Looking for a guide to fine tune the dimensions

Hi,

I designed a 3D print and printed it out. This was the 1st print I did which required precise measurements. I noticed that the print actually came out slightly smaller than the designed dimensions. So I am looking for a guide that can help me callibrate the XYZ movements to match the 3D object dimensions correctly.

Any guidance would be greatly appreciated.

Thanks,

Milind

RE: Looking for a guide to fine tune the dimensions

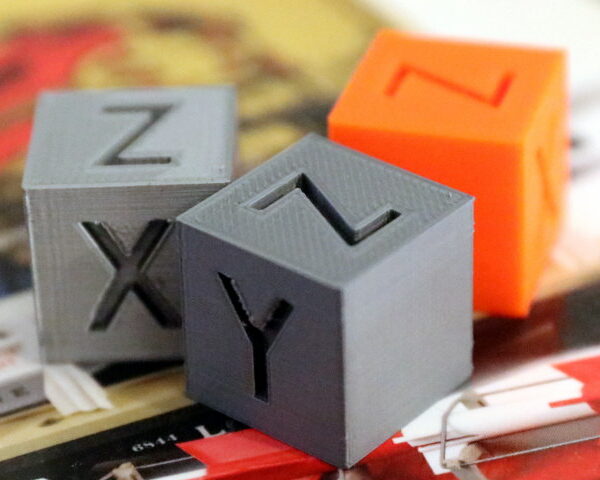

First of all, I suggest you print one or more of those standard 20mm calibration cubes and measure with a good digital or vernier caliper to get a base-level accuracy of your machine. Those below are PLA, ABS, and PETg, and ABS will indeed show some, but not much, shrinkage on cooling.

If you need very precise dimensions, such as holes into which shafts and registration pegs will fit, I suggest you do test prints using the same exact slicing parameters as your finished print, and fine-tune the dimensions on your model to zero in on the optimum size.