Is it bad that I've had to move the PINDA sensor down one revolution after installing a new nozzle?

hi y'all, sorry if this post comes off as really rambly but I've been so scattered and stressed with this entire thing and I'm honestly not knowing what I did wrong in anything, any help would be greatly appreciated

so this problem started about a couple days ago, when I was trying to match the settings of a really old good print I had. w/ the exact same settings, I was getting much worse results that looked really coarse and just bad in general, so I figured that this was a problem with hardware. in following with that, I eventually deduced that it was probably a partial clog, as I had been noticing filament generally came out curled in small purges. so following this, I tried a cold pull which didn't work, and I figured the only possible solution would be to replace the nozzle (I hadn't replaced the nozzle for about 6 or so months of having the printer. due to an apparent mistake I made, I accidentally bought an 0.8mm nozzle rather than the default 0.4mm that comes with the Prusa, but I just figured it'd be a good way to try a different nozzle size anyway so I kept it. I installed it w/ instructions, and I eventually got it to work, but when I tried to run calibration as I should with a new nozzle, the test probes kept crashing into my bed leaving dents, and then promptly stopping (I assume this is programmed in to prevent hardware damage). I was alarmed at this, since I assumed this meant I installed the nozzle incorrectly (please see second to last paragraph for more reasons why I thought this), but I figured the quickest fix to this was to move the PINDA sensor down as it was working (if it can't detect the bed when it's literally kissing it, probably move it further down). I did this, and mesh bed leveling worked correctly. however, when I was trying to level the bed, I was getting mixed signals because for some reason the left side of the bed was getting squished more than the right side of the bed??

I'm assuming this just isn't right, but I have no idea what's causing this as the entire bed leveling process is automated and I can't see the results of it. I know I can w/ Octoprint, but that would take at least another week to set up.

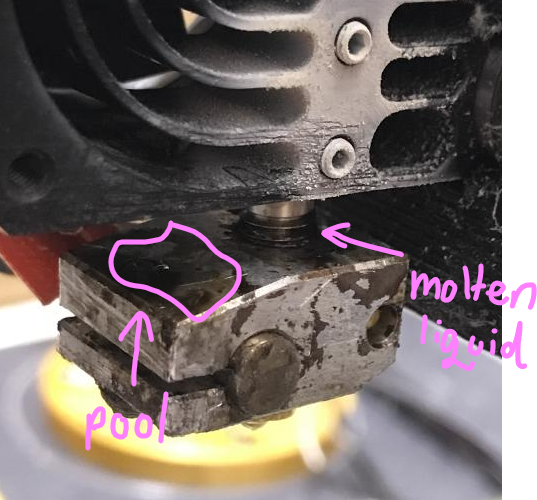

w/ regards to the nozzle being changed, this is the problem that I was having. right after I changed the nozzle, I looked at the entire heat block assembly, and I was noticing that there were these blobs of molten metal both on the heater block (probably not that bad) and on the screw (alarming?) I noted that the instructions were saying that if there were any leaks of molten metal that I should immediately stop printing, but I had no idea what was causing this as I made sure to tighten all parts.

honestly I'm really confused as to how all of these are connected, and if anyone could shed any light on what's happening I would greatly appreciate it. thanks y'all, I'll try to answer more questions to the best of my ability.

RE: Is it bad that I've had to move the PINDA sensor down one revolution after installing a new nozzle?

one other question I had was, would I need to disassemble the entire heatblock assembly and replace wires? I bought this printer as a kit and I'm slowly realizing I'm having to learn each part of it from scratch, haha

RE:

The leakage (I assume you mean molten plastic and not 'metal') around the threads of the hot end is, unfortunately, quite common.

It's almost always because the nozzle is not seated flush against the flat mating surface directly above it, either by not being close/tight enough or having debris in there that prevents a tight seal.

Remember that there's a lot of pressure in there, and if there is a leak, even tiny, the molten filament will find it.

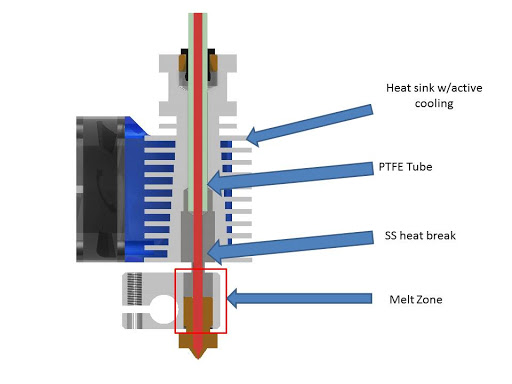

The circled (actually rectangular) melt zone below is where this is occurring.

Pay particular attention to the gap between the head of the nozzle and the heat block. If the nozzle is flush against the heat block, it's probably not seated properly.

RE: Is it bad that I've had to move the PINDA sensor down one revolution after installing a new nozzle?

I see, this makes somewhat of sense. I did mean molten plastic, haha, I'd be a lot more worried if it were molten metal somehow. I think I've fixed it, but just in case it does happen to resurface is this something to worry about as in introducing heat creep?

I am somewhat worried as well about the inconsistent layer heights but this definitely helps for me when I will hopefully add the replacement 0.4 nozzle back on. thank you!

RE: Is it bad that I've had to move the PINDA sensor down one revolution after installing a new nozzle?

The sudden terrible print quality out of nowhere was caused by the ptfe tube inside the hotend shrinking on my mini. I replaced the heatbreak with the Bondtech replacement, and Ive never had that issue happen again. On mine it happened after printing petg for an hour and a half, and after that my prints were all terrible. I print petg all the time now though and it works great.

RE: Is it bad that I've had to move the PINDA sensor down one revolution after installing a new nozzle?

There's a lot in the OP's original posts. @jsw has already explained the nozzle issue. What I would add is that it's important to tighten the nozzle hot, I use 285 degrees.

Is it bad that I've had to move the PINDA sensor down one revolution after installing a new nozzle?

No. Sometimes you have to move the PINDA to make sure you can get good Live Z, ideally around -1 because then you have plenty of room for finetuning up and down. I put this little gadget online to help with the adjustment: https://www.prusaprinters.org/prints/57192

some reason the left side of the bed was getting squished more than the right side of the bed

I would check the sheet for xz skew: https://help.prusa3d.com/en/article/xz-axis-skew-correction-mini_158518

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/