Idler screw will not unscrew

Hi all,

I'm having significant difficulty with my extruder idler screw. I have a Prusa Mini which is still pretty new (only a couple kg printed on it). I've been messing with the idler screw quite a bit trying to fix underextrusion problems with various different filaments. Now, I'm back on prusament PLA but the idler screw will not unscrew.

I have tightened the idler screw significantly and am unable to loosen it. I've always had difficulty unscrewing it but have been able to do it (sometimes I have to orient the hex key sideways); now, the screw is stripped enough that it will not loosen. Interestingly, I can still tighten it.

I've read suggestions elsewhere to reprint the extruder housing, but as I don't have another printer this isn't possible for me. I could theoretically get spare parts but I need to fix this asap and I would hope that Prusa's printers are a bit more resilient than that.

After numerous cold pulls and taking apart and experimenting with the extruder I believe that it is this screw which is causing jamming. Currently no clicking, just the extruder doesn't extrude at all.

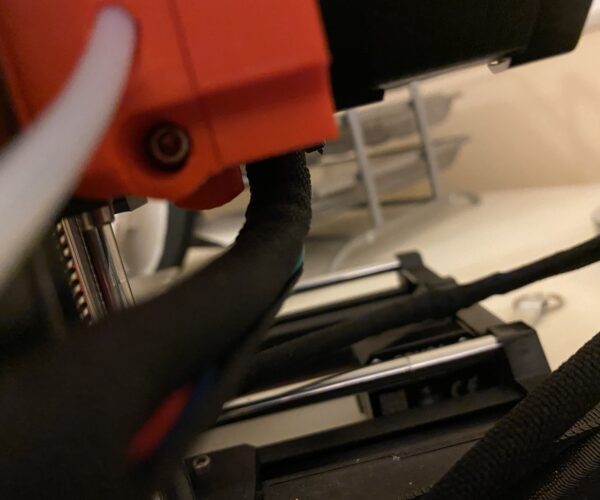

Any suggestions on how to loosen the screw? Picture attached.

Thanks for the help.

RE: Idler screw will not unscrew

Not that I'm defending Prusa for (not) being resilient, but in my opinion, it's entirely your own fault in this case -I'm sure you (will) realize that 😉

Now, here's what I would do... assuming you have a Dremel or similar.

First, I would take whole extruder off the printer, so bolt is more accessible and the whole extruder more manageable to work on. You can see, because bolt is fully screwed in, a small part of it is protruding out on back side (thread). There I would made a small thin cut, where I could then use normal (flat) screwdriver. Now I would be able to actually screw in the bolt from backside.. which would actually unscrew the bolt.

Yes, when making cut, you would damage extrusion lever a bit, but that won't impact it's working later. Needles to say, that cut should be made precise and patiently (that's why demounting whole extruder).

I'm quite sure that this should work. Other than that, I don't have a better idea (without making some damage).

[Mini+] [MK3S+BEAR]

RE: Idler screw will not unscrew

That's genius... I'd read about dremeling but never thought to do it from the back!

Yes I agree that it's user error... I guess as a first time 3d printer owner I hoped Prusa would be more resilient to user error. I've only seen a couple of other people online with this issue so its cause is probably pretty specific to something I did. But I think I assembled it correctly, and I also think my use of the idler screw has been pretty normal. Prusa support suggested replacing the nut and bolt (which of course was unhelpful because that's what I'm having issue doing) and said it might be an issue with one of them, because the bolt can screw in only one direction. My guess right now would be the screw got bent somehow as I disassembled the extruder for the fifteenth time trying to get flex and esun pla to work...

reply

Totally agree on possibility that bad thread on the nut caused your trouble. These insert nuts are more like an "emergency" solution and don't really suit the purpose in this case -because it's expected that user will adjust tension more than two-three times only. Bolt seems to be of higher quality and I can't imagine it would bend that easy.

Anyway, if you enjoy the printer and you're planing to experiment with various filament types, I recommend you think about Bondtech upgrade. Yes, is kinda expensive, but worth in my opinion.

[Mini+] [MK3S+BEAR]

Fixed!

Solved! It was the nut. But it was a lot of trouble to fix…

I started by hand sawing a ridge in the back end. I also tried using a clamp on pliers (a vice grip alone wouldn’t work). Both methods turned the screw and I thought I had fixed it! Until… I noted the nut was moving *in its casing*. Now I’m not sure why the nut threads got messed up (not at all ruling out it being my fault) but making sure the nut doesn’t move in its hole seems like it should be doable by Prusa.

To fix this I put a spare nut into the slot and clamped it such that the first nut could not turn. I was able to screw the back end in only so much, especially given the end was so rough. The slot I sawed turned into half the screw being gone and then I lost the whole quarter centimeter.

Anyways, what fixed it was drilling the screw out from the front. After I got through the bolt head I could just pull the two parts apart. I tried the nut with another screw and surprise surprise it would not go on.

Adventures with a Prusa mini… thank you very much for the help Bogdan. Now I’m just praying I have fixed the under extrusion by fixing the idler. The extruder casing got a little cracked but I believe it to have only an aesthetic affect. I do think I’ll have to upgrade to Bondtech in the not so distant future.

defective spring

Root cause of the issue - a defective spring. I noticed the extruder still wasn't working until I screwed the idler in almost a centimeter extra. The spring itself provides almost no force.

This must have caused me to continually overexert the idler screw/nut which eventually drove the nut to failure.

t

Glad you found the root cause of the problem. Still, I second Bogdan's suggestion to consider the Bondtech dual drive extruder upgrade if you intend to print in a variety of filament types. Installed them on my Minis, never had to change anything for any filament, everything just works.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

reply

...The spring itself provides almost no force.

For sake of comparison.. I just tried to squeeze the spring with my thumb, which is quite hard to do.. almost impossible to squeeze it fully.

I don't have original extruder installed right now. But if I tighten the bolt to the point where head is flush with extruder surface, then by feeling, lever already gives enough tension for gear to grip filament good enough. I mean, I can't imagine screwing the bolt all the way in, because tension would really be too high.

[Mini+] [MK3S+BEAR]

.

Thanks - that's actually quite helpful. Prusa support said that screwing in the bolt quite a bit was fine but the way the idler feels in hand just doesn't feel right. After reading your message I'll probably order a replacement screw just in case.

RE: Where to buy spring?

So I don't think I'd like to order a $2 spring from Prusa and pay the shipping costs... any recommendations on where to buy it?

reply

Because I just can't imagine spring could be damaged or faulty.. here's a stupid question: you did insert the spring on the right side of the bolt, right?.. hey, just making sure 😉 .

[Mini+] [MK3S+BEAR]