Extrusion issues

Hi all - out of the blue last night a print failed on me due to underextrusion, PLA filament completely stopped extruding halfway through. I am able to load and unload filament just fine, can purge when loading. But when I go to print, or even do the first layer calibration, it will extrude OK at first and then just stop after 30 seconds or so, the extruder starts clicking, and nothing comes out of the nozzle. I tried cleaning the nozzle, replacing it, (partially) reassembling/cleaning the hot end, tightening and loosening the extruder tension, no luck. Everything looks clean inside the hot end as best I can tell, and like I said it purges just fine when loading PLA filament.

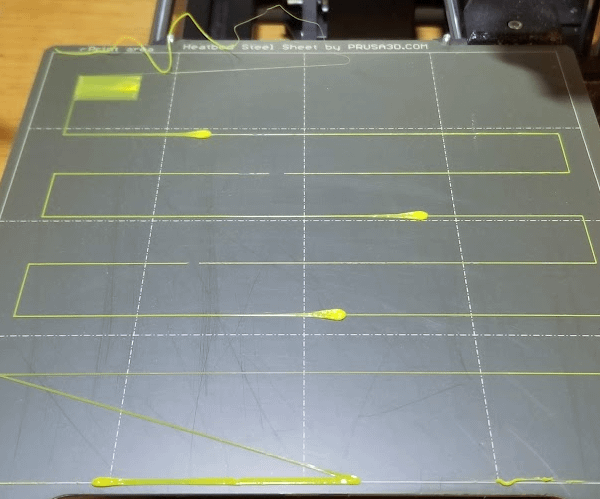

One thing I notice, when I load filament, I can purge just fine, but if, after loading and purging, I wait maybe 30 seconds, and try to purge again, then nothing comes out. I thought maybe things weren't hot enough, so I set the printer to PETG filament (230C extrusion temp vs. 215 for PLA) while loaded with PLA, and I was able to extrude a bit, however it would extrude ok, then start to underextrude, then spit out a large blob (see picture below from a first layer calibration run at these settings). So I'm not sure if this is indicative of my root problem, or just a side effect of extruding PLA at high temperature.

My system is a stock Mini+, using the default profiles for Prusament PLA and Generic PLA. I've been using my mini regularly for 2.5 years and have not run into any problems like this. I've tried all the troubleshooting guide and youtube videos I can find without any success so far. Any and all advice/guidance is much appreciated.

Best Answer by Tysonsw:

How does you PTFE tube look inside of the hotend?

You also have to make sure that your really tighten the nozzle against the heatbrake, and not to the heatblock.

https://help.prusa3d.com/guide/how-to-replace-a-heaterblock-heatbreak-mini-mini_122769#123322

RE: Extrusion issues

How does you PTFE tube look inside of the hotend?

You also have to make sure that your really tighten the nozzle against the heatbrake, and not to the heatblock.

https://help.prusa3d.com/guide/how-to-replace-a-heaterblock-heatbreak-mini-mini_122769#123322

Printer: Original Prusa Mini+

Nozzles: E3D 0.25, E3D Nozzle X 0.4 , E3D 0.4, Bondtech 0.6 CHL

Printables: Tysonsw

Mastodon: [email protected]

.

RE: Extrusion issues

Replace ptfe tube even if it looks ok sometimes they can get dented bent etc or you may have experienced heat creep take ptfe out and put new one in

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Extrusion issues

Thank you guys, I had replaced the PTFE tube recently for the spare that came with my kit, and it was about 2 mm shorter than the original. I didn't tighten the heatbreak against the tube. It's printing like new now 😀

RE: Extrusion issues

glad you found the cause

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models