Durability of smooth PEI sheet

How many hours of printing do you generally get before needing to replace the smooth PEI build sheet?

Mine seems to start losing adhesion with PLA even though I have been diligent in keeping it clean with IPA.

RE: Durability of smooth PEI sheet

I've been using the same sheet on my mk3 for about 2.5 years. That's the same side too as the reverse side I ripped a small section out with petg at the very start before I figured out that petg needs a release agent on the smooth sheet.

I also don't use IPA to clean it. Like many of the long term users here we take the smooth sheet to the sink and using a plain unscented no additives dish soap such as fairy/dawn give it a good scrub using clean paper towels. We then rinse it with lots of HOT water and dry with more clean paper towels. Then only handle by the edges afterwards to stop finger oils getting back on the sheet.

Yes IPA is the recommended way but dish soap just works better. Tim can go into the scientific reasons behind it but basically ipa/alcohols dissolve the grease into suspension and so can leave a micro thin film behind unless you use loads of ipa. Detergents like dish soaps are surfactants and surround the grease and then it washes away when you rinse. Also gallons of water rinsing vs a tiny puddle of ipa.

You just have to make sure the sheet is thoroughly dried afterwards as it is steel.

This method is NOT recommended for the textured sheets as the texture allows access to the steel below and the tiny spaces can trap water, making drying much harder and so the chances of rust are massively increased. You can still do it but you have to be alot more careful drying, I like to bake it on the printer for 20 mins to dry the textured out and if it does rust then that's on my and I cant complain to Prusa about it.

If adhesion gets really bad you can use acetone to replenish the SMOOTH sheet only. Acetone melts the top surface of the pei and so 'resets' it. Its to be done sparingly only. Theres an article on the Prusa Knowledge base about it. https://help.prusa3d.com/en/article/first-layer-issues_1804

RE: Durability of smooth PEI sheet

The keyword is sparing. I have used it for both the smooth and textured. It is not recommended for the textured but it will reset the surface if you can't get anything to stick.

I start with n escalation of forces type of approach:

-

Alcohol: I use it every few prints. I use 91% or better isopropyl alcohol. I spray it on a cool bed and let it sit for 10-15 seconds and wipe it off with a lint-free towel. Once in a while, an alcohol rinse is helpful to remove PLA residue. It does not remove finger oils as well as soap and water.

- Dish soap and water: Alcohol doesn't clean the body oils off the bed; soap and water do. I prefer Dawn dish soap. Wash the bed in hot water, use a fresh paper towel as a washcloth, with a few drops of plain dish soap. Rinse well in hot water - if you have very soft water, rinse a bit longer. If you are going to scrub the surface, use a non-scratch sponge. Try with a lint-free towel.

-

Acetone wash: Use very, very sparingly. This should be a last resort if you are considering tossing and replacing the surface. Do not under any circumstances soak the surface. Pour a 1-2 cm puddle of acetone on the bed. Spread it around with a fresh paper towel. It will evaporate fast as you clean. You do not want to leave it on there long. This step removes PEI oxides that form over time. It will improve PLA adhesion to a like-new state. I have 10 printers that use textured and smooth sheets. I have done this 4 times with great success in 3 years. This should what I mean by sparingly.

I do 1 and 2 every week. #3 have done only 4 times on two different sheets in 3 years. They were troubled from the start and it worked at resetting them when I consider tossing them.

Streak test: when contamination is suspected and after a wash

With a fresh piece of paper towel, and very clean fingers, dampen the towel with 91%+ alcohol, and wipe the bed side to side moving back to front, like you're painting it with alcohol. The alcohol should be thin enough on the towel it quickly evaporates. If you see any streaks, the bed is dirty and needs a wash.

--------------------

Chuck H

3D Printer Review Blog

RE: Durability of smooth PEI sheet

I've been using the same sheet on my mk3 for about 2.5 years. That's the same side too as the reverse side I ripped a small section out with petg at the very start before I figured out that petg needs a release agent on the smooth sheet.

I also don't use IPA to clean it. Like many of the long term users here we take the smooth sheet to the sink and using a plain unscented no additives dish soap such as fairy/dawn give it a good scrub using clean paper towels. We then rinse it with lots of HOT water and dry with more clean paper towels. Then only handle by the edges afterwards to stop finger oils getting back on the sheet.

Yes IPA is the recommended way but dish soap just works better. Tim can go into the scientific reasons behind it but basically ipa/alcohols dissolve the grease into suspension and so can leave a micro thin film behind unless you use loads of ipa. Detergents like dish soaps are surfactants and surround the grease and then it washes away when you rinse. Also gallons of water rinsing vs a tiny puddle of ipa.

Same here after more than a year and several hundred hours of printing on just one side of the PEI sheet. Still have a spare PEI sheet and don´t yet need it.

I actually use a small, rechargeable Bosch delta sander to rub kitchen towel paper across the PEI sheet vigorously....

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Durability of smooth PEI sheet

How many hours of printing do you generally get before needing to replace the smooth PEI build sheet?

Mine seems to start losing adhesion with PLA even though I have been diligent in keeping it clean with IPA.

I have been using the foiled and also the textured PEI printing plate from Prusa for about 2 1/2 years. With careful handling this is easily possible. With abrasive materials I usually stick a Kapton foil on the printing area to protect the coating. So I could print a lot of carbon containing materials, like Nylon or PEEK, without damaging the plate.

It is important that the print is not removed from the hot or warm plate by force. Then it could happen that a piece of foil is torn out.

Acetone should also not be used too often, because it makes the surface brittle and it could crack.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Durability of smooth PEI sheet

I'm still using my original smooth PEI from March 2018 with no issues. I just do regular washes with Dawn dish soap when adhesion falters and the occasional buffing with a 3M 7445 pad.

The reverse side was replaced after a bad experience with high-temp PETG. The replacement surface is also excellent, but it's not as pretty.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Durability of smooth PEI sheet

Thanks for all your posts! I guess I'll remove the PEI sheet from the shopping cart for now and just order the new Super MINDA.

I've been using one side of the sheet for PLA and the other side for PETG with glue stick. So I have been cleaning the sheet with soap + water as well. Now I have to figure out why the sudden lost of adhesion. Would low ambient temperature (<15C) contribute to that?

RE: Durability of smooth PEI sheet

I actually have tried a sander with 2000 grit sandpaper on on sheet. It had worked well.

--------------------

Chuck H

3D Printer Review Blog

RE: Durability of smooth PEI sheet

@alex-hung

I don't want to talk you out of buying a PEI printing plate, a reserve is always good if something goes wrong. And if you order something from Prusa, it is better to place a collective order to save shipping costs. Thermistor for bed and nozzle and also a nozzle fan can always be needed, because according to the forum discussions these parts often break down.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Durability of smooth PEI sheet

@karl-herbert

100% agree. Shipping can kill you.

--------------------

Chuck H

3D Printer Review Blog

RE: Durability of smooth PEI sheet

@cwbullet

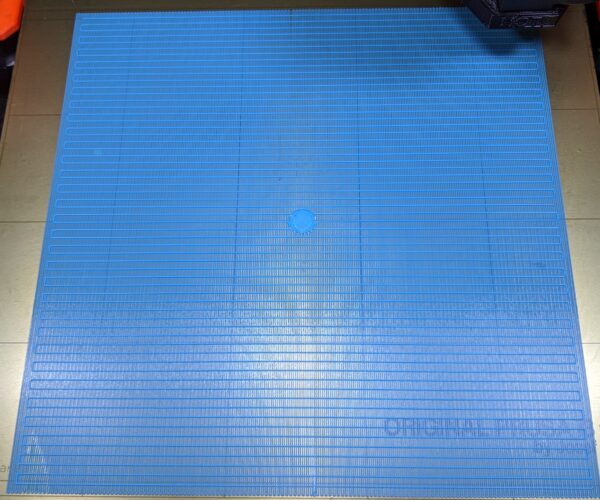

I always do the first preparation in the same way. 2000 grit sandpaper is stretched on this machine and carefully circles briefly over the entire surface:

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Durability of smooth PEI sheet

@alex-hung

I don't want to talk you out of buying a PEI printing plate, a reserve is always good if something goes wrong. And if you order something from Prusa, it is better to place a collective order to save shipping costs. Thermistor for bed and nozzle and also a nozzle fan can always be needed, because according to the forum discussions these parts often break down.

True! I already have a spare nozzle from when I originally ordered the printer. I’ll get another build plate just in case. Shame we don’t get the new satin plate 😢.

RE: Durability of smooth PEI sheet

[...] Shame we don’t get the new satin plate 😢.

I was able to order one yesterday. Are they out already?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Durability of smooth PEI sheet

@bobstro

I thought it is only for Mk3?

RE: Durability of smooth PEI sheet

Anyway, I was too slow to place the order and now the upgrade kit is out of stock 😢

RE: Durability of smooth PEI sheet

@bobstro

I thought it is only for Mk3?

Ah I did order for Mk3. Thought I saw it for both, but not so sure now.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Durability of smooth PEI sheet

As far as durability, I think the degradation will come from damage and not from use.

On one side of the original sheet, I pulled off a few pieces of the 'membrane' coating by not letting an ABS print cool down enough and/or not using a release agent. I got impatient and used a kitchen implement to pry the piece off and parts of the PEI came off with it. Lesson learned.

That side is still good for smaller parts, and I use it for PC Blend printing since I have not done that much and am still getting the feel of printing with it.

I have not seen any significant loss in adhesion. I usually use IPA (currently 99% technical grade) and sometimes denatured alcohol, which is easier to get around here. Very seldom I'll use Acetone prior to a print with a small footprint and/or small supports on the first layer, and usually use the Layerneer Bed Weld in addition with those. I have not yet had to use any abrasives.

RE: Durability of smooth PEI sheet

@alex-hung

At this time, I think they are selling it only for the ML3s. I am sure it will be available for the mini,

--------------------

Chuck H

3D Printer Review Blog

RE: Durability of smooth PEI sheet

@jsw

Defintly mostly from damage. Atleast that is what happened to mine.

--------------------

Chuck H

3D Printer Review Blog

RE: Durability of smooth PEI sheet

They just spoke about the satin plates for the Mini, they will be coming soon, but no date was mentioned.

My Mini has: A SuperPINDA + Bondtech Heatbreak + Bondtech Extruder installed