Correction for print size

How do I correct for printed size? Everything is printing about .5mm small in X and Y. Z is perfect. I am using this to print machining fixtures so I need to dial in the size. I'm using prusasilcer. I found some info talking about M500, M503. Some also talk about M92. I checked the belt tension they are ok. I printed all deferent kinds of test prints. Everything checks out. I am super happy with everything. I just need to tune in the size.

RE: Correction for print size

How do I correct for printed size? Everything is printing about .5mm small in X and Y. Z is perfect. I am using this to print machining fixtures so I need to dial in the size. I'm using prusasilcer. I found some info talking about M500, M503. Some also talk about M92. I checked the belt tension they are ok. I printed all deferent kinds of test prints. Everything checks out. I am super happy with everything. I just need to tune in the size.

Hello and welcome to the Prusaforum!

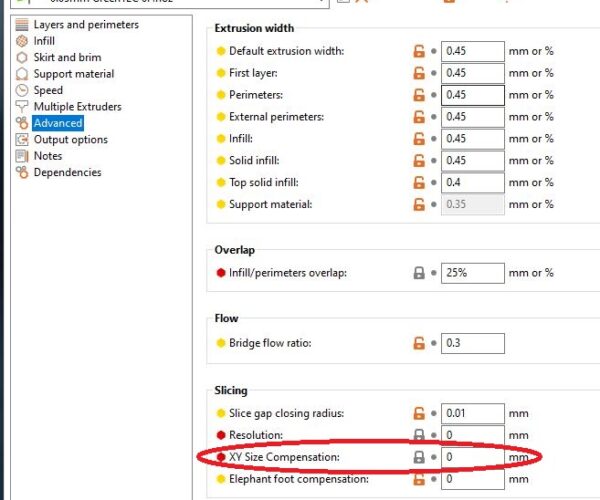

An easy way to correct this is to use the Slicer:

Also you should calibrate your extrusion multiplier. You have also to consider the material shrinkage (0.5 - 1%).

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Correction for print size

What Karl mentions makes small features larger (or smaller), it does not compensate for an XYZ calibration issue. You need to either recalibrate (if that is where the problem is - X & Y scale change due to changing belt tension for example), or, rescale the part during slicing.

There's a third area where scale can be a problem: but since you only see an X and Y problem, not Z - the printed part can shrink or even grow during and after the printing is complete. Most plastics have a thermal expansion coefficient.

RE: Correction for print size

In such cases I always make a test print before I print the entire component and make any necessary corrections. Holes, for example, I usually design somewhat larger (0.1 to 0.3mm) in CAD.

However, to get into the range of +-0.1mm, it probably takes some trials. There are simply too many parameters and materials which have an effect on this.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Correction for print size

@tim-m30

I will try the setting in the slicer first and see how that works. I'm getting similar results with PLA and PETG. I would like to know more about how to recalibrate. If you could point me to a resource that would appreciated.

RE: Correction for print size

Calibration procedure is usually in the assembly manual or printing guide ... try page 14 of the printing handbook that came with the printer -- though I also suggest you start by reading from the first page until the last - the information in these manuals is important and will save you time and trouble.

ps: that said, the mini may not be dimensionally as accurate as the Mk3 nor include calibration points in the heat bed. In that case you'll need to make adjustments outside the firmware.

RE: Correction for print size

@tim-m30

The manual they sent me is in German. I emailed them for new one. They sent a link to the online assembly guide which only has the assembly. They said there is no pdf version. Apparently they are unwilling to send me an English copy.

RE: Correction for print size

@dpar15

the manuals are online

here is a link to the printing manual

https://www.prusa3d.com/downloads/manual/prusa3d_manual_mk3s_en.pdf

here is a link to the new user guides page

https://www.prusa3d.com/new-user-mk3/

the prusa3d.com page has links to a load of useful information,

https://www.prusa3d.com/

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Correction for print size

There's a third area where scale can be a problem: but since you only see an X and Y problem, not Z - the printed part can shrink or even grow during and after the printing is complete. Most plastics have a thermal expansion coefficient.

RE: Correction for print size

When you need accurate dimensions on parts, adjusting the XY size compensation may not give you the results you expect. For example, if the distance between 2 holes is not accurate then the XY size compensation is not going to fix that. In my former life designing plastic injection molds, one always designed in the shrink factor of the material being molded. The same can be applied to 3D printing. Some materials shrink more than others. You can compensate for this by scaling the part in the slicer before slicing. Scale the part up by the shrink factor for the material to be used. Using this technique may fix the issues you're seeing with accuracy. At least it's another option to try.

RE: Correction for print size

I found a solution that works. I scale in fusion 360 just in the X and Y. I found the scale function in Prusa slicer to be not accurate. It varied quite a bit depending on the size of the part to be printed. Also you can only use 2 places after the decimal point, which on small parts is not fine enough. I also tried the XY size compensation mentioned in an earlier post and that basically adds size to each surface( i.e. Holes are smaller and outside sizes are bigger). I found using fusion 360 I can use the same scale amount for any size part and is the same for PLA and PETG. Have a sticky note with that amount on my desk. 😉

RE: Correction for print size

@dpar15

The advantage of most CAD systems is that axes can be scaled individually or differently. I always do this in CAD and name the part e.g. "partxxx_PETG".

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.