All Prusa MINI prints winding up failed

Hi all,

I've only had my Prusa MINI since September and unfortunately I've gotten a limited number of successful prints out of it. At first it was simply a bed leveling issue where mid way through prints I was witnessing the nozzle raising from the object and no longer placing PLA material. After figuring out that the MINDA probe needs to go through first layer calibration each time my prints worked for a while but now I'm faced all of my prints winding up like this:

I'm not sure if this is due to the nozzle being raised mid print, but sometimes this failure state results in me being unable to purge filament and the nozzle being clogged. I then have to heat the nozzle to 250 C and use the cleaning needle on it to get any material out.

I'm getting quite sad over not being able to use my 3D printer pretty much at all without issues. I essentially only print PLA at default settings and have gone through Prusa support's MINDA probe troubleshooting guide ensuring the height is correct and that the sensor is operational.

I'm reluctant to use the custom warm up code as I'm under the impression that flashing custom firmware voids your warranty.

Just unsure how to proceed cause as it stands my MINI is a very expensive paperweight. Thanks so much for your insight in advance.

RE: All Prusa MINI prints winding up failed

You certainly shouldn't have to do the calibration before each print, so something is clearly wrong! How far does the nozzle go above the print, and is it consistent every print? Do you have a video of the fault occurring?

Customising the start g-code isn't the same as flashing custom firmware, so you don't need to worry about that.

RE: All Prusa MINI prints winding up failed

look at the extruder [tension | gear] it could be that the gear is full of 'shaved' filament or/and the extruder tension is not right for your filament.

Stock MK4S with FW 6.2.6

RE: All Prusa MINI prints winding up failed

You certainly shouldn't have to do the calibration before each print, so something is clearly wrong! How far does the nozzle go above the print, and is it consistent every print? Do you have a video of the fault occurring?

Customising the start g-code isn't the same as flashing custom firmware, so you don't need to worry about that.

Gordon, thanks for your post! I think it's only moving slightly above, as if I do a lowering live adjust the second the underextrusion over the open portion of my print occurs as shown in my first post's photo I can salvage the print.

I'm sorry to say I don't have a video at the moment but I can try to take one. I've wasted enough PLA at this point to justify it.

RE: All Prusa MINI prints winding up failed

look at the extruder [tension | gear] it could be that the gear is full of 'shaved' filament or/and the extruder tension is not right for your filament.

Thanks for your response oxygen.

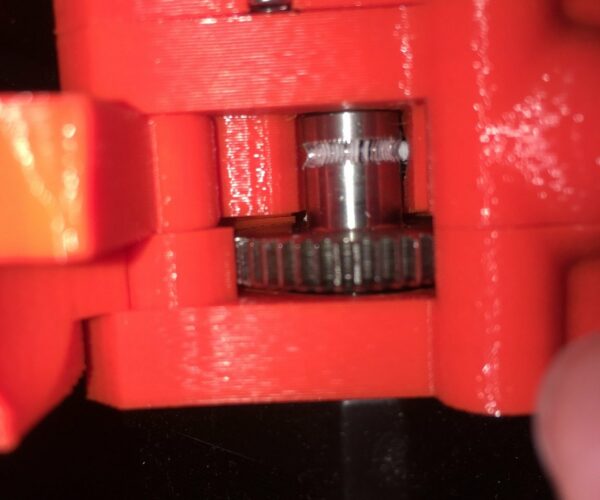

I have taken pictures of my filament extruder gear and it does look a bit clogged with filament.

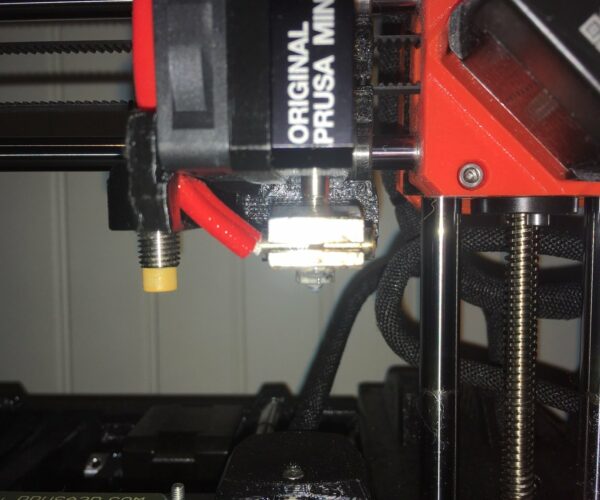

One thing I've also noticed is a lot of early MINI buyers had a nozzle/heatbrake that was too low. Would you fine folks say mine is sitting too low as well? In the "Avoiding early MINI problems" post a gentleman who was having issues with his printer constantly clogging and failing (not dissimilar to my current experience) raised his nozzle up by 10 cm and fixed his issues.

Thanks again, all.

RE: All Prusa MINI prints winding up failed

Looks like mine height wise.

Does the first layer print ok if you don't calibrate? I.e does it start failing higher up but you've just start calibrating to get a successful print? Any clicking noises? I had filament in my gear because of a blockage in the nozzle. I would potentially follow this guide

https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mini_112011

I ended up changing the ptfe tube as it was short 23mm Vs 23.4 to spec and it all started working again.

Fyi I'm not an expert only had my printer less than a week.

RE: All Prusa MINI prints winding up failed

Hi all,

I've only had my Prusa MINI since September and unfortunately I've gotten a limited number of successful prints out of it. At first it was simply a bed leveling issue where mid way through prints I was witnessing the nozzle raising from the object and no longer placing PLA material. After figuring out that the MINDA probe needs to go through first layer calibration each time my prints worked for a while but now I'm faced all of my prints winding up like this:

I'm not sure if this is due to the nozzle being raised mid print, but sometimes this failure state results in me being unable to purge filament and the nozzle being clogged. I then have to heat the nozzle to 250 C and use the cleaning needle on it to get any material out.

I'm getting quite sad over not being able to use my 3D printer pretty much at all without issues. I essentially only print PLA at default settings and have gone through Prusa support's MINDA probe troubleshooting guide ensuring the height is correct and that the sensor is operational.

I'm reluctant to use the custom warm up code as I'm under the impression that flashing custom firmware voids your warranty.

Just unsure how to proceed cause as it stands my MINI is a very expensive paperweight. Thanks so much for your insight in advance.

Have you tried using a different USB drive than what came with the printer? I had a similar issue and replacing the thumbdrive fixed it. If you rproblem resembles mine: https://streamable.com/zbbnu1 then this should fix it.

RE: All Prusa MINI prints winding up failed

@ dakoda84

You don't need to flash custom firmware for warm up routine. Just put the appropriate gcode in the printer settings under custom gcode at start gcode section. When you slice it it will put the code in there and will run when you print it. I found the warm up routine works for me 9 times out of 10.

RE: All Prusa MINI prints winding up failed

look at the extruder [tension | gear] it could be that the gear is full of 'shaved' filament or/and the extruder tension is not right for your filament.

Thanks for your response oxygen.

I have taken pictures of my filament extruder gear and it does look a bit clogged with filament.

One thing I've also noticed is a lot of early MINI buyers had a nozzle/heatbrake that was too low. Would you fine folks say mine is sitting too low as well? In the "Avoiding early MINI problems" post a gentleman who was having issues with his printer constantly clogging and failing (not dissimilar to my current experience) raised his nozzle up by 10 cm and fixed his issues.

Thanks again, all.

I see a few things here and you are very much correct. The heat break/block is way too low and needs to be pushed fully in. Unfortunately, you will also need to cut (or order) a new PTFE insert at the correct length for this fix to work correctly.

A major sign of this is that the extruder gears are quite jammed with filament "dust". The best solution is to tear down the extruder and clean it properly, but if you are not comfortable doing that I would contact Prusa support as they are better suited to navigate this issue.

Upping the temperature in this case is not ideal. It seems like a logical fix, but it is not appropriate for this problem as you would have to re-tune an entire filament profile in the slicer to prevent globs and strings.

Just my 2 cents. Cheers!

Edit: Oh, if you decide to order additional consumables and you live far away from the Czech Republic, order a few parts at a time to help with shipping costs. I automatically ordered spare thermistors, heater carts, PTFE tubes and other bits to limit this cost on my end. Don't go overboard, but focus on the things that will eventually give due to wear.

RE: All Prusa MINI prints winding up failed

Additionally, do not forget to adjust the MINDA probe when you change the heat break offset. This is kinda important.

RE: All Prusa MINI prints winding up failed

Thanks all, I sincerely appreciate each every one of you trying to help me out here.

I'm going to start by raising up the heatbreak and then I'm going to adjust my MINDA probe. I'll try to clean off the extruder gears as best I can. Then I'll also add some of the warmup g-code since I've finally figured out how to do so!

I will report back some time this weekend, fingers crossed. Thanks everyone!!

RE: All Prusa MINI prints winding up failed

Go slow and take your time! 🙂 I dunno what your experience level is with doing maintenance, but these changes are quite minor and normal. Like all things 3D printing, precision is key. Sloppy mechanics == Sloppy prints.

RE: All Prusa MINI prints winding up failed

Hi everyone, thank you again for all of your insights and replies.

I took the advice given to me in this thread and raised the hotend up into the extruder. I followed this video:

Voila! Just like that my prints have been perfect. I am hoping this luck holds up and I sincerely wish this was the state I got this printer in because I could not be happier.

I guess I am just curious as to why this actually fixes things? As I said this is my first 3D printer ever and I stoked to learn more, but an explanation as to why this fixed the problems described earlier in this thread would be awesome.