G-code expert needed, or maybe other slicer than PS?

Hi,

I've been trying to find the best settings for my model for over one day, but long story short, i need some help from a g-code master!

I'll upload my model here: https://we.tl/t-Ftx3nSPry1

I would like to make the extruder in the mid section of my model to follow a simple circle movement (according to model) and then cross the circles with a simple straight move, the way a infill travel would do. At the moment the slicer makes the extruder travel about 4 times more than it should.

The reason i need help is print times. For the moment, the model estimated print time is ~36 hours, but with that optimization i would be able to reduce the print times in under 10 hours. The walls thickness is 0.6 mm, with the idea in mind that when set the extruder width to 0.55 mm, the slicer would generate a code that will only pass once trough each area. Of course this didn't happened and i'm still stuck with way to much travel and over complicated motion of the extruder head.

So if someone could help me or guide me trough the magic of g-code, it would be awesome!:D

If other slicers can do this please share your thoughts.

RE: G-code expert needed, or maybe other slicer than PS?

Could you please load the file on the forum, rather than using an external site which will only lets you download the file after accepting cookies and advertising.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: G-code expert needed, or maybe other slicer than PS?

@joantabb

I have no idea how to upload anything but images or videos. Is there on option for files?

RE: G-code expert needed, or maybe other slicer than PS?

The forum only accepts a few file types, it does however accept .zip files. So if you zip it up first and then use the attach file button it should work fine.

RE: G-code expert needed, or maybe other slicer than PS?

Thx for suggestion!

Here is the file: Br v4

RE: G-code expert needed, or maybe other slicer than PS?

@razvand21

Try Cura. There are some experimental settings to optimize the travel paths. Otherwise, manual programming of a simple gcode, e.g. circles and lines only require basic knowledge in gcode programming that can be learned quickly.

STL and other files you can upload as compressed files over "Add Media".

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: G-code expert needed, or maybe other slicer than PS?

@karl-herbert

I have just tried Cura, but with no success. If anything, Cura is less customisable. Can you point me where to learn some G code?

RE: G-code expert needed, or maybe other slicer than PS?

Travel moves are not a limiting factor here. You're printing outer/inner walls most of the time. You can go with 0.6 nozzle and 0.35 layer height, 0.55 width and bumping up the speed for this type. Still you're near 36 hours. With this settings you're already printing almost 50mm/s outer walls with ~6mm3/s volumetric speed. That's pretty fast. You could technically double it to 12mm3/s but even then it would be ~20 hours print time.

You would also loose a lot of quality and rigidity on this part with this settings.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: G-code expert needed, or maybe other slicer than PS?

@razvand21

You can increase speed and nozzle diameter, but this is always at the expense of quality and attention to detail. If you are interested in Gcode programming, especially for Marlin, then have a look here.

https://marlinfw.org/meta/gcode/

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: G-code expert needed, or maybe other slicer than PS?

@nikolai-r

Thanks for the tip. This is why i need custom G-code. PS "see" the geometry as perimeters, instead of circles and straight lines. I could easily print circles and straight lines at 150 mm/s with much longer and fewer moves of the nozzle. Infills are set to 200 mm/s now and it's ok.

I also choose 0.35 width for extrusion because of the estimated filament use. I save ~30-40% of total object mass over a wider extrusion setting for the same geometry. I know it's counter intuitive but with 0.55 with the total mass would be ~550 grams, with 0.35 it's ~360 grams.

RE: G-code expert needed, or maybe other slicer than PS?

@karl-herbert

Loosing quality is not a problem for this part, as the exterior is a cylinder, so there are no details to begin with. But i choose the 0.35 width extrusion for saving filament (less mass for the same object).

Thx for the link! I'll read g-code stuff tomorrow:D

RE: G-code expert needed, or maybe other slicer than PS?

PS "see" the geometry as perimeters, instead of circles and straight lines. I could easily print circles and straight lines at 150 mm/s with much longer and fewer moves of the nozzle. Infills are set to 200 mm/s now and it's ok.

I'm not sure I can follow you. Are you talking about ARC commands (G2/G3)? If yes, they are currently not supported either in Cura or PS. Everything is a linear move G1. But even with G2/G3, you can't achieve your aimed 10 hours print.

Best you can do is 100mm/s print. And this is something you can achieve already in PS with regular settings. There is no magic gcode required. You're hitting the max. possible extrusion speed with the MK3. With this settings your print time is 32 hours.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: G-code expert needed, or maybe other slicer than PS?

have you considered changing the extrusion width to 0.55mm and increaseing the external perimeter speed a little that will reduce the number of extruder moves significantly. and produce a stronger print than using 0.35mm extrusion width with a o.4mm nozzle

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: G-code expert needed, or maybe other slicer than PS?

Shortest time I managed to get to to was with changing to 0.55mm extrusion width and that was 1d 6h. The problem is not the path planning.

The print is hitting the Max volumetric setting of 15 for PLA for the hotend. It simply can not lay enough plastic down to print any faster. Even the 15mm/3 that Prusa sets for PLA is I think optimistic, I usually drop mine to 12. You would need a printer with a higher capacity hotend like a Volcano or similar to increase throughput.

Also trying to print with extrusion widths less than your nozzle diameter is not recommended. It can lead to problems and make your prints weaker.

RE: G-code expert needed, or maybe other slicer than PS?

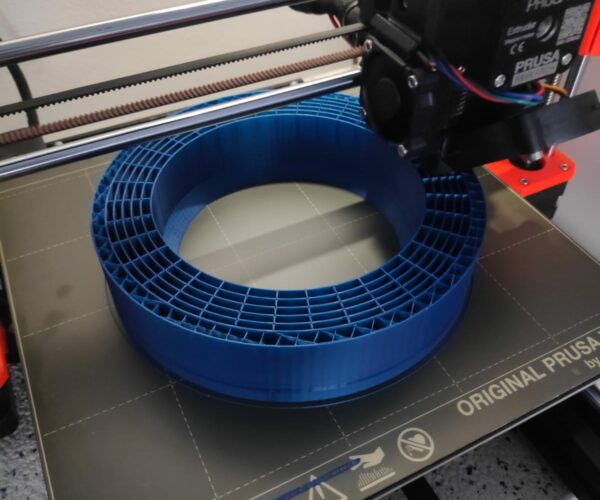

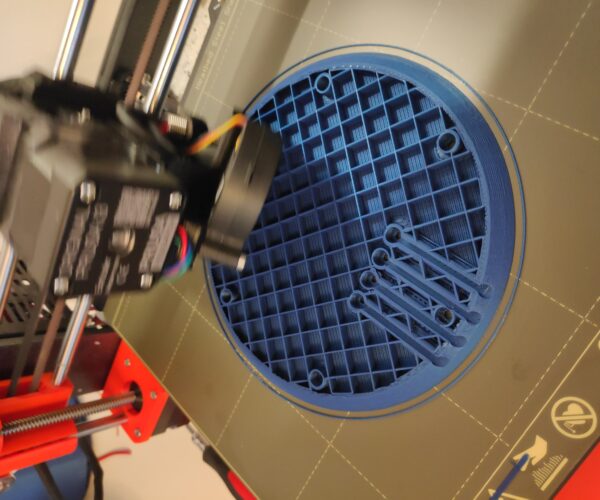

This is what i mean by slicer g-code optimisation. This way you can extrude with faster speeds, use less filament, and it requires way less time to print. Hope this helps to understand my point. I can extrude circles with 0.8 width and 0.25 layer height, with no problem at 150mm/s. And combined with less moves(only one pass over each layer) it would give much better results and print times:)

RE: G-code expert needed, or maybe other slicer than PS?

how can i post the video?

RE: G-code expert needed, or maybe other slicer than PS?

[...] This is what i mean by slicer g-code optimisation. This way you can extrude with faster speeds, use less filament, and it requires way less time to print.

Is this something you've actually seen applied to FFF 3D printing, or just an idea you have. Yes, you can draw the shape more efficiently, but notice that your drawing has a lot of lines crossing, which can cause filament to accumulate at the intersections on successive layers. If the slicer skips the intersections for the crossing lines, you get weaker walls due to the resulting small gaps.

The slicer thinks in terms of shells. Current slicers can't look at an entire model and identify different strategies to be used for different parts. Everything is broken down into shells which are sliced into layers and extruded as perimeters or infill. Newer slicers should start incorporating arc moves but not every printer implements those moves consistently. They'll still be looking at a model as shells.

Hope this helps to understand my point. I can extrude circles with 0.8 width and 0.25 layer height, with no problem at 150mm/s. And combined with less moves(only one pass over each layer) it would give much better results and print times:)

Keep in mind, your nozzle doesn't come up to speed instantaneously. Take a look in preview mode after slicing to verify actual speeds being attained. 0.8mm extrusion widths with 0.25mm layer height and 150mm/s speed is 30mm^3/s volumetric rate. You may start having problems with some filaments at those rates with the E3D V6 hotend. A lot will depend on your filament selection.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: G-code expert needed, or maybe other slicer than PS?

@bobstro

Thx for the comprehensive reply. I am aware of the cross path of the layers in my intended g-code optimization, but this is how i currently print rectilinear infill: 200 mm/s and 0.8 extrusion width with 0 problems. I'm using prusament pla for the moment and i'll try prusament petg soon. I also fave a clip with exactly that "problem" of cross path. In reality it's not a problem at all, maybe because of the layer height or the fact that the extra material can be squished in the empty space around. I'll post a picture and a video with exactly those settings on my i3s showing the noise it makes when it intersects the lines, although the end result is very strong and good looking too:)

Regarding the acceleration/speed, using my intended g-code, it would allow much higher speed because there are no corners. The only limit would be the volumetric capacity of e3d v6. Until now i could not see that limit, because of the sliced g-code with tight corners and small rectangles in general.

RE: G-code expert needed, or maybe other slicer than PS?

[...] this is how i currently print rectilinear infill: 200 mm/s and 0.8 extrusion width with 0 problems.

Rectilinear infill is fine for filling spaces and providing a layer of support for top layers, but it's not suited to structural walls.

[...] the fact that the extra material can be squished in the empty space around.

In sparse infill, there is space for overlapping extrusions to expand into. Alternating layers are printed at different angles. Great for filling empty space, but this approach is not suited to structural walls.

[...] Regarding the acceleration/speed, using my intended g-code, it would allow much higher speed because there are no corners. The only limit would be the volumetric capacity of e3d v6. Until now i could not see that limit, because of the sliced g-code with tight corners and small rectangles in general.

What you are describing is a completely (and so far as I know, unproven) approach to slicing. I'm sure if it were trivial, slicer developers would be using this strategy today. This requires more than just a few gcode tweaks to implement. If I'm interpreting your video correctly, this is a task that the human brain is well suited to but a real challenge to program.

Slicers can and hopefully will be optimized over time, as will 3D printers. I don't think a slicer with the capabilities to analyze a large part such as yours and select optimal strategies for portions of a print based on shape is on the short-term horizon.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…