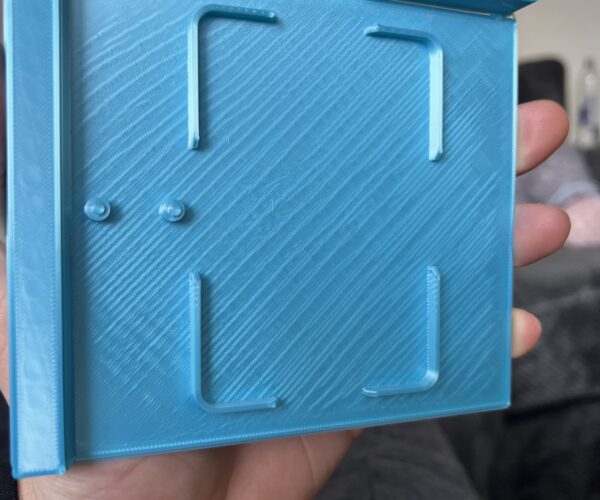

Wave or roughness in center

Greetings!!I am a newbie to 3d printing , but I’m a cnc machinist who self programs and who also used CAM software.I recently bought the mini+ because I also sell on Etsy . We are a retro reproduction game based store who creates game cases.I’m having an issue that I can’t seem to resolve and have tried multiple prints with different PLA brands and colors.Was wondering if you could help me identify what is created waves or rough patches in the center of my Turbo Grafx 3d printer case Pictures attached!

heat bed 60 deg Celsius

nozzle 200C

Recent prusa purchaser. Any recommendations will help.

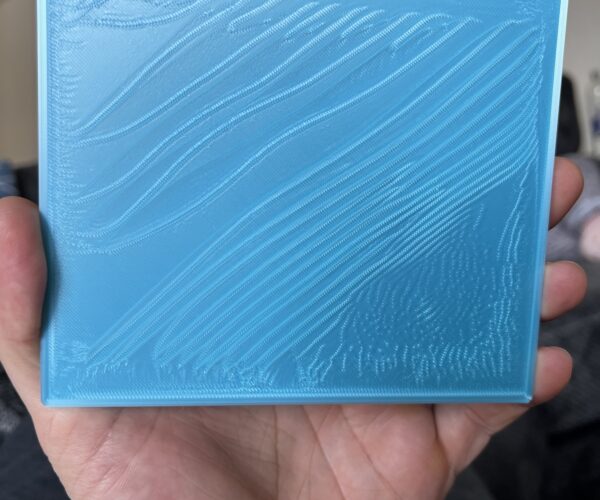

The bottom is smooth but has waves with slight roughness between them

The extruded front is rougher with waves possibly because of the first layer.

RE: Wave or roughness in center

*** also

I’ve tried raising my live Z , and using 200 C nozzle /60 heat bed and the first layer didn’t stick to the plate .

if I go down more, it’s more squished . Is it my temperature nozzle and heat bed ??

Let's get the first layer right - it's the foundatiom for everything else...

Your first layer 'Z' calibration is too low. Raise it until you *just* get rid of those first layer ripples.

If a smooth first layer is not sticking, or if it's warping like your example, then the next thing to look at is print-sheet cleanliness.

Clean the sheet with dishwashing detergent (Dawn/Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

Cheerio,

RE: Wave or roughness in center

You can try calibrate with this: https://www.printables.com/model/36706-bed-level-test to get an idea how your bed level is.

RE: Wave or roughness in center

Since the top solid layer is rippled I would say that it is over extruding. Sure you could raise the first layer to fix that part however the rest of the model has too much material.

Check your filament with digital calipers that measure to two decimal places, check your filament in a a few spots. Turn it 90 degrees as some filament is a little oval. Take and average and use this value in Prusa slicer. Usually that will be all you need to do, then you can calibrate your first layer.

There is also the extrusion multiplier, however this is more of a fine tuning feature that works better when used sparingly after everything else is calibrated. It's good for maybe a weird filament or a little tweak mid print.