RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@treyrey64

I understand, thank you... Vase mode is per definition a single outer wall with thickness of a single extrusion, but someone clever could have invented inside/outside wall or zig-zag and made it two walls thick. And that would have been interesting... 🤔

I know about thicker wall width and that do make the "vase" more strong in PETG. Never tried PLA.

Have a look at my models on Printables.com 😉

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@rgustafson

PTFE tubes are cut by a machine they made themselves. But there could be some bad piece, even machines have bad days. Person assembling it should have spotted it though and throw it away.

I remember seeing a tube cutting machine in a tour video I watched. This was very much like if someone were to cut it with side cutters though, on both ends. I have tubing cutters at work as a mechanic, it's not hard to do a good job with tubing. Machines having bad days is the leading cause of work for me every day, haha.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Had my Mini for a week now. Have yet to get a complete print. I will say that I have a handful of other Prusas, so I feel like I can troubleshoot most things. Also I haven't felt like spending 24/7 on this. Basically the filament gets jammed somewhere or ate by the gears. I've adjusted the hotend, put in the spare tube (which was a bit longer), removed the extruder and examined it (everything seemed ok) and messed around with the tension screw.

I swear the tension screw is almost all the way out. It's the only time I've been able to get past 2 layers for the most part. I did notice in the manual it said to have the screw head flush with the part when no filament is in, and that you should be able to push it through easily? It seems like mine, no matter what is always super tight.

Anyone have any other suggestions?

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@g-j-sieben

What size are those three grub screws? Nothing I have fits and the kit I ordered has 2.0mm (too big), 1.5mm (too small).

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@samuel-l6

Remove the bowden tube and see if a piece of filament slides through easily.

I noticed that if I tighten down the brass caps at the ends of the bowden tube it makes it too hard for the extruder to push the filament through.

All your filament are belong to us!

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

I had less than 20 hours of printing with the new Mini before I experienced the same under extrusion problems. I am running the latest 4.04 firmware. Over the past few days I've adjusted the feeder tension, performed several cold pulls, checked the inner PTFE tube for length and fit and replaced the nozzle. Nothing solved the problem except for boosting the nozzle temperature an addition 25-30 degrees for PLA. I have two i3 MK3S that operate flawless. The Mini produces excellent prints once it is dialed in. Can we all be doing something wrong?

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@corywest

I received 3 extra grub screws in a small "spare parts" bag with my mini.

According to these cheap calipers, the allen-wrench that fits in the grub screw is 1.5mm

And the grub screw itself is a 3mm (2.89mm)

All your filament are belong to us!

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

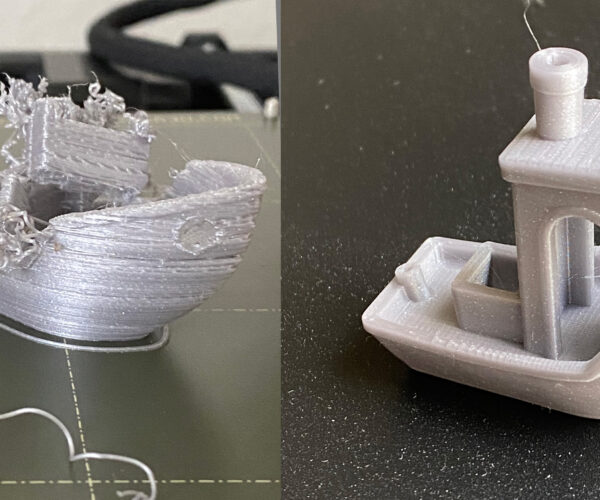

have u try this

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@rick-m12

Heh, Maybe just a little... Hope that didn't happen halfway into a long print.

I'm betting you'll have this thing dialed-in perfectly today.

All your filament are belong to us!

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Sorry I hadn't come back to report. After trying everything, I ended up getting it to print by upping the print temp by 15 degrees. I'm guessing because the fan blows at the nozzle. I'm ok with it for now. It's printing super nicely.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@frankincell

It was a ~30 minute test print and it looks like it failed about half way through. First I preheated for PLA, pushed down on the filament until it started to extrude then pulled it out of the hotend. Then I cut off the melted end on the filament and ran the unload function multiple times until the filament was out of the extruder. I reattached the loose end of the tube making sure it was tighter than it was before and reloaded the filament. It’s been working fine since.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@frankincell

Thank you. I had some fit issues but was able to get them out with a 1/16th wrench. Adjustments made and the printer is happier for it.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

I had the same problem as the original poster, except I've only used Prusament.

Prints less than an hour seem to work fine. Longer prints fail and jam.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

i was having the same problem and like marc-c13 i turned the temp up with the same results it has to be a software glitch as whenever i load a sliced model the nozzle temp sets its self at 170 degrees even if i set the temp at 215 in the slicer so that might be happening when the nozzle cloggs but i still have to print at 235 degrees to get good adhesion.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

Hello Guys!

+1 ….not really happy to join the "poor guys facing extruder issue" cluster.

Paid in advance, 4 months awaiting delay, and to receive a printer which extrusion fail after couple prints….not Serious mister Prusa!

HELLO MISTER PRUSA? ANY ROBUST SOLUTION ON THE WAY?

Hopefully you all guys gave nice approaches and solutions

I confirm by the way that PTFE tube diameter is dangerously close to 1,75 at both brass rings crimped on PTFE tube. So already drilled it with Dremel and 2mm drill bit.

On the way to solve it….

Best regards

Sylvain

J'essaye de faire, mesurer et partager...plus pratique que théorique, peu de blabla, des résultats… La preuve incombe à celui qui affirme….en faisant et mesurant

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

@cruff180

It seems to set it to 170º when it initially probes bed. Then it raises the temperature before printing.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

As an update to my original post I have been printing every day using PLA with the nozzle temperature between 235 and 250 degrees depending on which manufacturer of filament I’m using. The prints have been coming out flawless. It’s not the cure but it is a solution at this time until Mr. Prusa can solve the temperature issues.

RE: Prusa Mini: Filament frequently jams after about 2 hours of printing

My problem was fixed by closing the gap between the heater block and the heatsink. Like in the video in the first post, or info on these Prusa pages:

Use the instructions on this page, but you don't have to actually replace the PTFE tube.

https://help.prusa3d.com/en/guide/how-to-change-a-hotend-ptfe-tube-mini_119449

After adjusting the gap, I needed to move my MINDA up and re-do the Z-offset.

See step 26 of How to change a M.I.N.D.A. sensor - MINI - Prusa3D