RE:

Luckily there is no believe needed anymore, please do the experiment in "My Tech Fun"s video with your food dehydrator and see if you can compete (2g water on a sponge with milligram scale, heat and measure wheigt of sponge after 30 minutes and 60 minutes of heating. Then see (and report here) where your food dehydrator is on the diagram I posted from the video.

Drying filament is nothing like drying a sponge. My experience is from dozens of rolls of filament printed, both PETG and ASA, dried in a food dehydrator. The print quality improvement is unmistakable.

Regards,

Mark

I talked with my older son today on this, and he works as student assistant in a robotic institute for more than 3 years now. They are 3Dprinting >100 rolls of filament per year and do not use any filament dryers. He said there are slicer parameters that can reduce stringing instead. I will see whether I can get my MINI+ stringing reduced that way.

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

The effects of moisture in filament are highly dependent on what shapes & features are being printed, as well as what material is being printed. Your son's operation might use filament fast enough that it doesn't pick up significant moisture. Some regions have persistently low humidity & don't need to dry filament. Stringing is only one of the effects of moist filament. I print a lot of tight-tolerance items that don't work unless I'm using dry filament.

Whatever you find to do with your hands, do with all your might!

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

The effects of moisture in filament are highly dependent on what shapes & features are being printed, as well as what material is being printed. Your son's operation might use filament fast enough that it doesn't pick up significant moisture. Some regions have persistently low humidity & don't need to dry filament. Stringing is only one of the effects of moist filament. I print a lot of tight-tolerance items that don't work unless I'm using dry filament.

He told me that they print with PLA, PETG, Nylon, ...

Used rolls (they use many different colors) are lying there for months before being used next time.

Also they do multi-part prints where nozzle has to move from one part to the next.

They don't have any special environment for printing, not dry.

Hi questioned that my Fillamentum PLA roll that is opened for only 14 days can show moisture effect.

He told me in case I cannot get rid of stringing with my MINI+ by settings in PrusaSlicer, I should first try with an oven to see whether that has any effect.

I will try with PrusaSlicer, and if that does not help, try the oven first.

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

for me it's impossible to let unsealed filament laying for months at my room without silica gel. My room humidity is around 50% and reach more than 80% when it's raining. Not even months, if i forgot to put the PLA filament in storage for just one day, the print results will shows bubble that can caused a bad stringing and. Especially the nylon filament, i have to dry it with eibos cyclops for at least 3 hours at 70'C before i print the nylon to get better results. I'm curious how low the humidity level in your son workplace. Or maybe can you ask him what filament brand that they use?

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

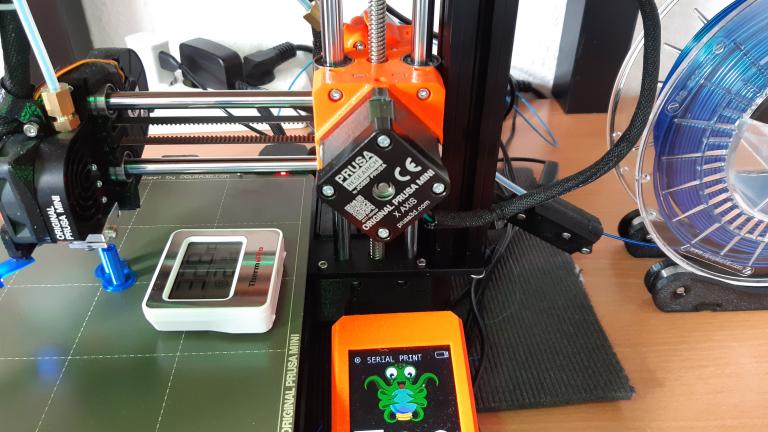

6 of my son's robotic institute Prusa printers were moved to robotic exhibition in 2019.

As you can see the spools are on top without anything around and without filament dryers.

They use these 3Dprinters as shown in the youtube video in the institute as well, here video for completeness:

"The official Universal Robots ROS Driver Powered by FZI"

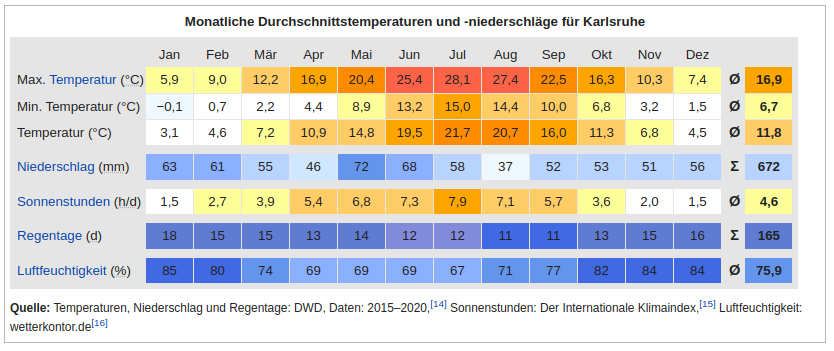

Regarding humidity question, the institute is located in Karlsruhe/Germany, which might have a higher humidity than normal in Germany because the city is located at big river Rhine. Just looked up Wikipedia on humidity (bottom row, "Luftfeuchtigkeit" in German), year average is 75.9% humidity. But I am not sure how this translates to rooms inside a building:

https://de.wikipedia.org/wiki/Karlsruhe#Klima

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

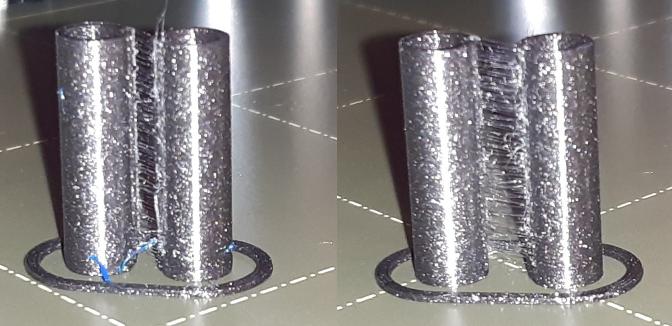

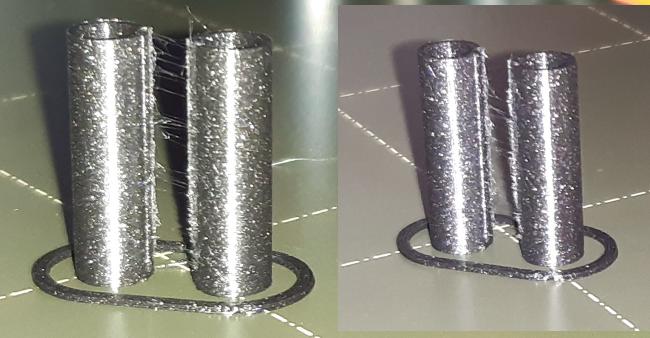

I did another test with my Fillamentum PLA, two parts close, with lots of stringing. Photo captured with nozzle camera:

I did print the gcode with sample Prusa PLA (left). That was opened 3 weeks ago as the Fillamentum PLA when I received my MINI+. After I realized that gcode was creaed for Fillamentum PLA, I used PrusaSlicer to create gcode for Prusa PLA (right). It seems that right has worse stringing though:

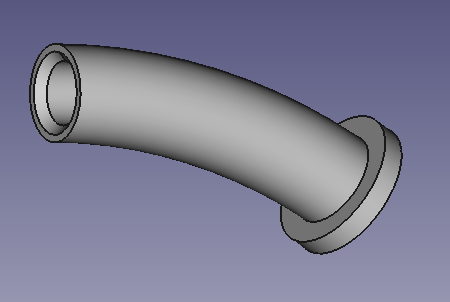

Finally I prepared for heating elements to arrive. I constructed and printed several filament transport pieces, until finally this 30° of holed torus with 2.75mm inner diameter and 0.4mm chamfers on both sides worked:

I placed it into a hole of the size needed into Ikea Samla box, and used that without issues for the Prusa PLA sample prints:

The box is 50% too high, but MINI+ spool holder and filament spool do fit inside.

Put one of those filaments in an oven at 50 degrees for a few hours then retry the print.

Cheerio,

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

Thanks, I will try that after having verified that oven 50°C setting really gives 50°.

Last night I tested unload/load of filament into/out of Ikea Samla box, both works with 3Dprinted filament transport part.

Unload:

Load(+purge)

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

you should use PTFE tube. Don't use that small pipe like the one you printed. It will create more friction an squeaky noise

RE:

you should use PTFE tube. Don't use that small pipe like the one you printed. It will create more friction an squeaky noise

Thank you, I did order PTFE tube yesterday, should arrive today:

https://www.amazon.de/gp/product/B07VHJ62RV/ref=ppx_yo_dt_b_asin_title_o01_s00

Posted by: @diem

Put one of those filaments in an oven at 50 degrees for a few hours then retry the print.

Cheerio,

As said I wanted to verify that our old oven does heat with 50°C when marker is set on 50°, and it did not. I placed sensor of digital thermometer inside oven and digital display outside, with thin cable in and out. It was below 50° marker to get 50°C, but I had to change settings the whole 2 hours of print for preventing going above 54°C or below 46°C.

Then I placed the 2h heated Prusa MINI+ sample PLA inside Ikea box ...

... and printed the two parts close, which had shown so much stringing in the previous postings of this thread.

I did record the whole printing from my 2nd borescope nozzle camera:

wget http://octopi3ap:8081/?action=stream

Then I converted recorded 9:32min mjpeg stream to mp4, took 2.5 hours on my Raspberry Pi400:

time ffmpeg -i index.html\?action\=stream -c:v libx264 -preset veryslow -crf 18 output.str.mp4

Finally I used ffmpeg to cut out few seconds of video, crop and convert to animated .gif with 2 passes using gifenc.sh:

pi@pi400-64:~ $ cat `which gifenc.sh` #!/bin/sh # doc: http://blog.pkh.me/p/21-high-quality-gif-with-ffmpeg.html # needs: ffmpeg palette="/tmp/palette.png" #filters="fps=15,scale=320:-1:flags=lanczos" filters="scale=-1:-1:flags=lanczos" ffmpeg -v warning -i $1 -vf "$filters,palettegen" -y $palette ffmpeg -v warning -i $1 -i $palette -lavfi "$filters [x]; [x][1:v] paletteuse" -y $2 pi@pi400-64:~ $

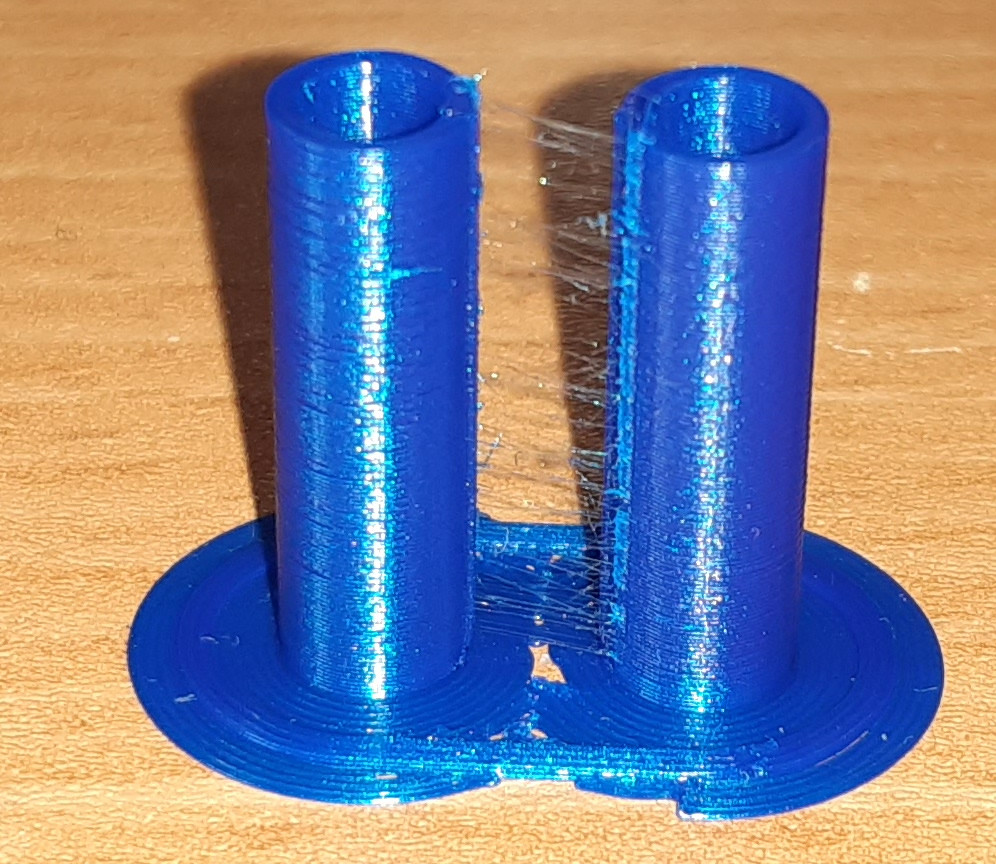

As you can see there is nearly no stringing left with same PLA and same gcode as before, only a single string at bottom. Only a little frayed PLA on left part, I believe on what I saw here with 2h oven time, more oven time would avoid that as well:

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

As you can see there is nearly no stringing left with same PLA and same gcode as before

So in spite of whatever magic is occurring in your son's lab, am I correct that you have now convinced yourself spool drying *is* beneficial?

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

not only PLA, i often print using PETG, and i always dried the filament using EIBOS filament dryer before printing, the results is very good.

here is my stringing test using eSUN PETG

RE:

As you can see there is nearly no stringing left with same PLA and same gcode as before

So in spite of whatever magic is occurring in your son's lab, am I correct that you have now convinced yourself spool drying *is* beneficial?

Yes.

And even more, I did 3Dprint the same parts 17h and 25h after I printed the stringing free parts. PrusaSlice said that filament length for the parts was 0.25m, and I measured that this is a bit less than the whole way from extruder through PETG tubes through filament sensor to the outside. So the first parts (left) were printed completely from filament that was dry 17 hours before and was completely inside MINI+ PETG tubes. As can be seen (left) this did not prevent from stringing again, not even less than filament from the box after 25 hours (right). I took both photos with smartphone flash, because that made stringing easily visible:

Between the two prints shown I tried several other same parts prints, and they all failed, adhesion of part(s) got lost.

One example video can be found here:

https://forum.prusa3d.com/forum/english-forum-awesome-prints-hall-of-fame/hall-of-shame/paged/2/#post-591535

So when 3Dprinting these parts close together next time, I will create a new gcode file with brim enabled as countermeasure to adhesion loss (I did clean heatbed with isopropanol before each failed print).

Given the 17h experience, it seems that I will have to unload filament into Ikea box for drying with heating element, and load again when drying completed.

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

Do you have a way to measure the humidity levels in the room where your printer is located? I would have to assume that the robotics institute where your son works has gone to lengths to control humidity in that environment. Nevermind the filament, you wouldn't want a moist environment for any of the type of equipment they have. I am a woodworker, and I store my wood inside, 4' away from a dehumidifier. In 24 hours a piece of wood can change dimensions or warp if the moisture content is excessive or inconsistent from surface to surface. My point is, that I was experiencing issues when the room didn't "feel wet" but once I added an actual dehumidifier it has eliminated those problems.

It would be interesting to know what the turning point is for filament in terms of relative humidity. In other words, what % does it have to be where you wouldn't actually need special drying/storage and the filament does just fine in the room's normal airspace. Too dry isn't healthy for humans of course, but sometimes we need to make sacrifices for our projects haha.

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

Do you have a way to measure the humidity levels in the room where your printer is located?

I had not, but ordered bluetooth hygrometer (±2% humidity, ±0.5°C) yesterday:

https://www.amazon.de/gp/product/B093PT1NL1/ref=ppx_yo_dt_b_asin_title_o01_s00R

Room temperature before print done was 22.2°C with 39% humidity.

During print I placed it onto heatbed.

Temperature raised to 32.8°C only (heatbed temperature was 60°C), and humidity directly on heatbed went down to 21%:

Despite room humidity only being 39% the undried filament did show massive stringing again:

(as stated before I created gcode again, this time with brim enabled to enhance adhesion of parts)

RE:

Plastic molders set a limit of .2% to .02% moisture and dry their plastic before molding. I've found the quality of prints always improves with drying, and I live in a very dry climate. I always dry my filament in a food dehydrator before printing. Don't get so hung up on stringing that you ignore other quality issues. With the Mini, adjustments that improve stringing on test objects often make the surface quality worse otherwise. It may be a compromise and you may have to accept some minor stringing that can be easily removed.

Regards,

Mark

RE:

Posted by: @hermannsw

Despite room humidity only being 39% the undried filament did show massive stringing again:

Thanks for following up with those numbers. Your humidity definitely seems quite low. With my dehumidifier running 24/7 the lowest I can achieve is 35%. I came across this video last night that you might also find interesting:

Posted by: @mark-3

I've found the quality of prints always improves with drying, and I live in a very dry climate. I always dry my filament in a food dehydrator before printing.

I was discussing this topic with a friend who has been into 3D printers for over a decade and he commented that in his experience the filament producers had, over time, figured out formulations to make them less sensitive to moisture and thus he had not had any issues "for years". He doesn't use a dryer or do any special storage. What is your opinion? Do you feel that the current day "premium" filaments are less dependent on drying, or do you experience benefits drying no matter what? His primary filament is Matterhackers Tough PLA fwiw.

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

Posted by: @hermannsw

Despite room humidity only being 39% the undried filament did show massive stringing again:

Thanks for following up with those numbers. Your humidity definitely seems quite low. With my dehumidifier running 24/7 the lowest I can achieve is 35%. I came across this video last night that you might also find interesting:

Posted by: @mark-3

I've found the quality of prints always improves with drying, and I live in a very dry climate. I always dry my filament in a food dehydrator before printing.

I was discussing this topic with a friend who has been into 3D printers for over a decade and he commented that in his experience the filament producers had, over time, figured out formulations to make them less sensitive to moisture and thus he had not had any issues "for years". He doesn't use a dryer or do any special storage. What is your opinion? Do you feel that the current day "premium" filaments are less dependent on drying, or do you experience benefits drying no matter what? His primary filament is Matterhackers Tough PLA fwiw.

As I already stated, results for me are always better after drying, full stop. If they are good enough for someone else without drying, great. I have a dryer right here and there is no reason not to use it.

Regards,

Mark

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

As I already stated, results for me are always better after drying, full stop. If they are good enough for someone else without drying, great. I have a dryer right here and there is no reason not to use it.

I wasn't trying to be a source of irritation, I was just trying to analyze your experience a bit more. I did not see any place where you indicated what brands you had tried, and/or whether anything had changed over the years. The video I linked shows filament rolls literally submerged in tubs of water for over 24 hours. And yet they print better (or at least "less stringy) than what Herman is seeing with a low humidity environment. So is it 100% just down to the moisture content or is there some variability between brands and materials as well? That is what I was trying to explore a bit more. Nobody is suggesting you fill the dehydrator with fruit from now on 🙂

RE: Printing multiple (same) parts at he same time using Prusa Slicer (sequential)

During my searches I found fixed temperature heating elements, bought 40°C and 50°C versions powered with 5V:

https://www.aliexpress.com/item/1005003394446635.htmlI don't need a filament spool mentioned in DIY version, will use the spool holder that came with my MINI+.

Will see on 3/21 how it will work ...

Today 40°C, 50°C and 60°C versions arrived (in Germany, from China), two of each kind.

I used an airtight closable glass box with plastic top, and inserted bluetooth hygrometer (on top of mini breadboard) and two 50°C heating elements.

They did heat up from 22°C room temperature only very slowly, and ended at 36.7°C (I gave them hours):

So definitely those two elements are not powerful enough to heat even the small box to 50°C.

I will try with all 6 elements tomorrow (powered from constant voltage power supply) and see how much closer to 50° C I can get.