Nozzle Cleaning Advice

In the last few weeks, my Mini has logged over 3 days of printing time. I've used Black PLA (Comgrow and Prusament), Purple PLA (Hatchbox), and Orange PETG (Hatchbox).

I had always used a brass brush to clean the nozzle on my Creality E3V2 with no issue. However, the first time I used a brass brush on the Mini, there was an unnerving event. Something shorted; sparks flew and the machine shutdown. After a brief pause, cycling power restored operation with no apparent damage. Needless to say, I am now reluctant to use a brass brush on the Mini again.

I found a non-conductive nozzle brush which uses felt pads. I've been using that on the Mini ever since. It works fairly well, although the pads foul quickly and it is not as effective as a brass brush at removing stubborn buildup.

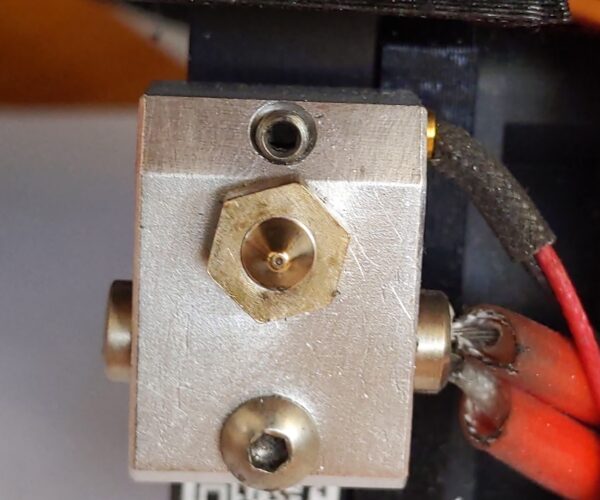

I can keep the nozzle tip clean with the felt brush, but the nozzle hex nut and heat block are very messy. The residue actually prevents a 7mm socket from easily fitting over the nozzle (although the Prusa wrench still fits fine). Sometimes it appears that bits of this residue fall off and mar an active print (e.g., black blobs in the middle of an orange print). Since I never see any purple or orange residue, I assume the problem is not related to a leak in the nozzle/PTFE junction. Also, I've never had a filament blob form around the nozzle.

Comments or suggestions?

RE: Nozzle Cleaning Advice

It may sound crazy but I use a toothbrush with nylon bristles.

RE: Nozzle Cleaning Advice

You can use a wire brush. Either be very careful around the thermistor and heater cables, or just turn the power off after heating the hotend to target temperature. It will stay hot long enough to do the cleaning job.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Nozzle Cleaning Advice

As has been said just turn the power off and consider a silicon cover for the heat block as well, there are a few moulds you can print off on prusa printables.

RE: Nozzle Cleaning Advice

You can use a wire brush. Either be very careful around the thermistor and heater cables, or just turn the power off after heating the hotend to target temperature. It will stay hot long enough to do the cleaning job.

As has been said just turn the power off and consider a silicon cover for the heat block as well, there are a few moulds you can print off on prusa printables.

Many thanks! I repeated the following cycle three times:

- Heat nozzle to 260° C

- Hold temperature for 10 minutes

- Power down and disconnect power supply

- Turn printer on side/front

- Remove residue with brass brush, probe, and scouring pad while useful heat remained

- Cooldown

And the result:

Quite a difference...

Must say: I am not impressed by the exposed conductors! What gives Prusa? I came way too close to frying the electronics as a result of this oversight.

I ordered some silicone socks to mitigate future build up. Anyone know why Prusa does not even offer a sock as an accessory? They're the only manufacturer I've come across that does not ship their printers with a sock.

I appreciate how very helpful this community is.

RE: Nozzle Cleaning Advice

Aah, a beauty! Reminds me to do the same at next maintenance.

Re sock, suffice to say that it's like religion, some believe in them, some (like me) don't. Maybe Prusa doesn't. The more interesting question for me is why they didn't ship a standard E3D v6 heater block, so any E3D sock would fit, for those who believe in them 🙂

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Nozzle Cleaning Advice

It may sound crazy but I use a toothbrush with nylon bristles.

Thanks. I'll give that a try for daily cleanup.

RE: Nozzle Cleaning Advice

First, clean the nozzle using a damp cloth or an alcohol wipe while the nozzle is hot. This may cause some steam but will indeed remove any material clinging to the nozzle. If this doesn't work, you can also use a wire brush, small blade, or needle to remove any remaining debris from the nozzle.

RE: Nozzle Cleaning Advice

Must say: I am not impressed by the exposed conductors! What gives Prusa? I came way too close to frying the electronics as a result of this oversight.

Are you sure you didn't damage the wire insulation with the wire brush, the first time you brushed it and it sparked?

RE: Nozzle Cleaning Advice

Are you sure you didn't damage the wire insulation with the wire brush, the first time you brushed it and it sparked?

I took many pictures while I was performing the initial assembly. I reviewed the close up picture of the hotend and, no, those exposed conductors were there from the very beginning.

RE: Nozzle Cleaning Advice

I only have one picture showing wires on me, and it looks better but not a great angle.

I’m away from the printer now, but I’ll check my printer later and see if my insulation goes all the way up. I’m assuming what you have is not how it’s supposed to be, and you may be able to get a replacement heater from Prusa under warranty.

RE: Nozzle Cleaning Advice

First, clean the nozzle using a damp cloth or an alcohol wipe while the nozzle is hot. This may cause some steam but will indeed remove any material clinging to the nozzle. If this doesn't work,you can also use a wire brush, small blade, or needle to remove any remaining debris from the nozzle.

RE: Nozzle Cleaning Advice

I would turn the printer power off, before using a wirebrush on the nozzle,

a number of folk have damaged their controllers by shorting the wiring around the print head.

Companies, like Bigtreetech are now adding protection against this issue to theit newer boards, like the Manta Series.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Nozzle Cleaning Advice

Been there, done that 🤣

RE: Nozzle Cleaning Advice

First, clean the nozzle using a damp cloth or an alcohol wipe while the nozzle is hot. This may cause some steam but will indeed remove any material clinging to the nozzle. If this doesn't work,you can also use a wire brush, small blade, or needle to remove any remaining debris from the nozzle.

I know it has been suggested elsewhere but I am not a fan of flammable alcohol on a hot nozzle. The only Isopropyl Alcohol I keep on hand is 99% and I would be concerned it could catch fire and burn with the almost invisible alcohol flame. Maybe lower concentrations won't burn easily. I heat the nozzle up and use an Exacto blade to scrape off the grunge and finish with a wire brush. I use silicone socks that keep almost everything clean, so I only have to clean the nozzle itself. The heater block stays clean and I don't have to get any metal tools anywhere near the wiring.

Regards,

Mark