My attempt to make the Z-Axis more rigid

Sorry in advance for my rudimentary english,

I hope this will bo not a big trouble to read this topic.

As i do like my Mini so I do not like to look at this flexible Z-Axis.

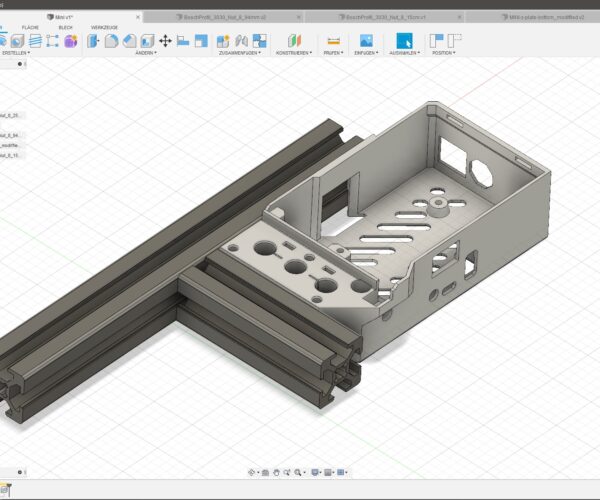

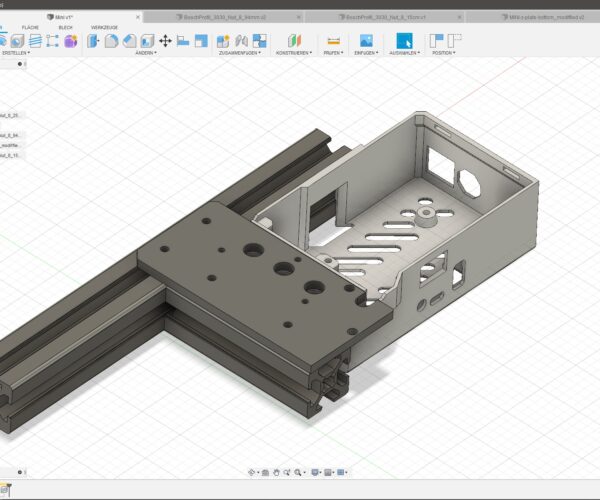

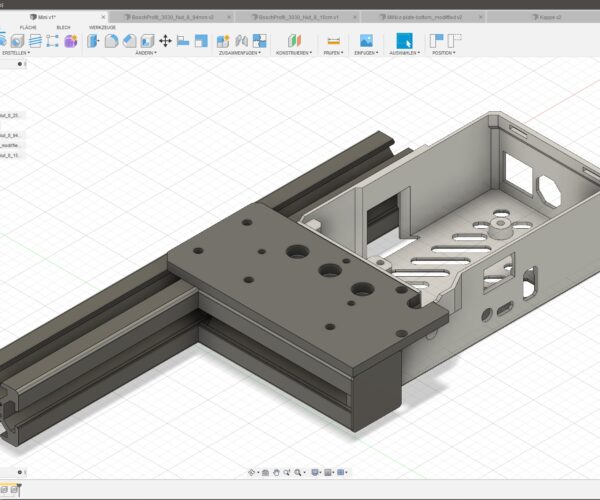

So I want to try to make it more rigid, my idea:

- 94 mm 3030 Nut 8 Alu profile

- 1mm cap for the end of the new 3030-piece

- sliding blocks, M4 screws and other necessary stuff to mount it

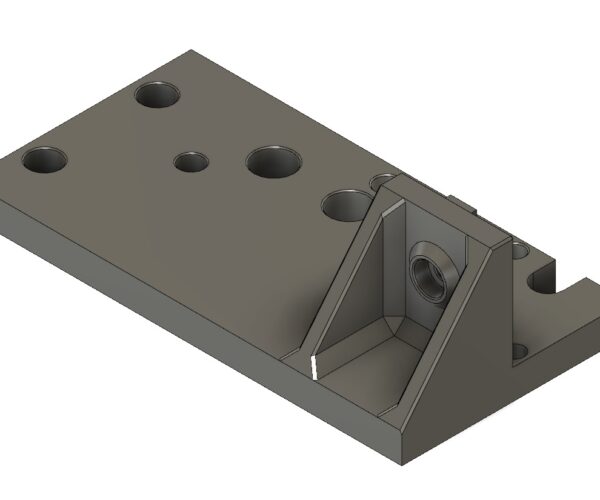

- a slightly modified MINI-Z-Platte_bottom (5mm Aluminium)

- a slightly modified Mini-Z-Bottom

Now there will be a larger Z-Platte so the Z-Bottom only need one fixing sliding block instead two of them.

Also I am able to make this design more compact if i do remove the one Sliding block and it's fixture.

I am able to made such a plate on a mill, is nothing complicated.

Just a flat 5mm Aluminium-Platte with some holes

And at the end, there will be a 1mm cap for the 94mm 3030-Profile.

I just want to throw this Idea to this forum, maybe someone has a bit more refined idea.

What do do all of you are thinking about this?

Kindly regards.

RE: My attempt to make the Z-Axis more rigid

Maybe try something like this:

https://www.prusaprinters.org/prints/32054-prusa-mini-z-axis-support-brace

or this

https://www.prusaprinters.org/prints/51415-prusa-mini-z-axis-brace/comments

Personally I use the first model and it preforms great for what it is. Of course you can make something similar but in alu - for extra rigidity

RE: My attempt to make the Z-Axis more rigid

I like the idea a lot! I wish instead of one straight plate and plastic 3D printid electronics box housing, they make T or L-shaped profile which sits firmly against 3030 extrusion. This would help make XZ perpendicular, less twisted and more rigid (metal to meatal rather than metal to plastic).

Those braces are good, but make sure your printer is not crooked in first place while printing it 😀

RE: My attempt to make the Z-Axis more rigid

@pinkie-pie

I already tired some of these parts. But they do not solve the problem at its root also these part are pretty useless if you do want to print them on an already twisted Mini.

You do have to print them on a properly aligned printer first, they may help to stiffen the Z-Axis but does not help to make the X-Axis perpendicular to the Y-Axis.

Of course you can try to bend and twist the Mini but this is only a matter of few movement / prints and the Mini will bend by itself due to movements / vibrations.

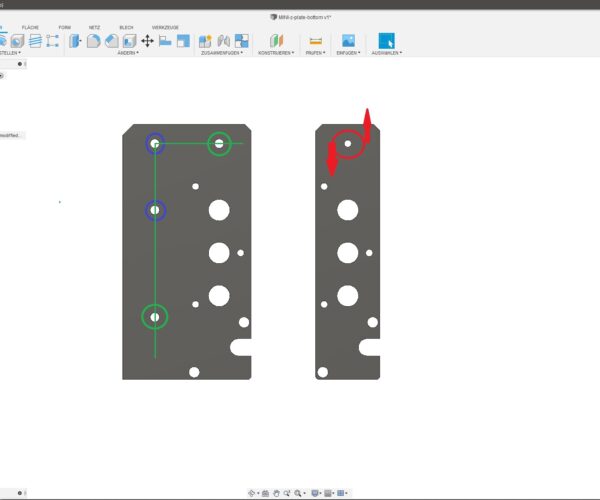

The issue here is that the Z-Platte only has ONE screw connection to the base instead at least two.

As shown in this picture, you can see, the method with only one screw connection (red circle) works like a lever point.

You do need at least two points (green circles) for a proper aligned X and Y axis .

The connection point in the blue circles are not necessary but nice to have for a firm connection.

I also thought a night about my first draft and had a nice second idea:

I will do a second version with 3030-Aluminium corner joints:

This will be cheaper and there is no need to order an additional 3030-Profile anymore.

Kindly regards.

RE: My attempt to make the Z-Axis more rigid

@p-stock

If you make some, let me know. I’ll buy one from you!

RE: My attempt to make the Z-Axis more rigid

Hi,

I do want to make a little update:

- I did a new prototype of the Z-Platte which is full printable.

This is the Version 1.0:

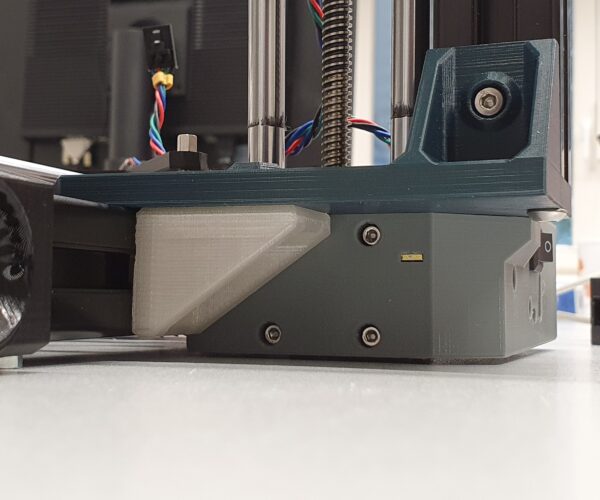

And mounted it's looks like this:

Now the plate is 8mm strong and printed of PLA with appropriate slicing settings to get it as stiff as possible.

This was already pretty decent, much better than expected and thanks to the additional joint on the Z-Axis there was much less wobble on the Z-Axis.

But there is still a bit room for improvement, so I will made few changes and a printable corner joint with will match to this platte and the extrusion of the Y-Base.

There will be a Z-Platte made out of aluminium, but I am still waiting for the parts and in this pandemic-times everything is taking much more time...

Meanwhile I will make a proper working solution which is full printable for every one who does not have the possibility to make an out of aluminium but I will still provide a version which is optimise to be made full of aluminium so all people will be pleased 😀

RE: My attempt to make the Z-Axis more rigid

Hi,

I just want to leave an update on my project.

So first: I tried the version with the printed Z-platte and printed corner joint.

But this does not works out well... Not as rigid as is should be.

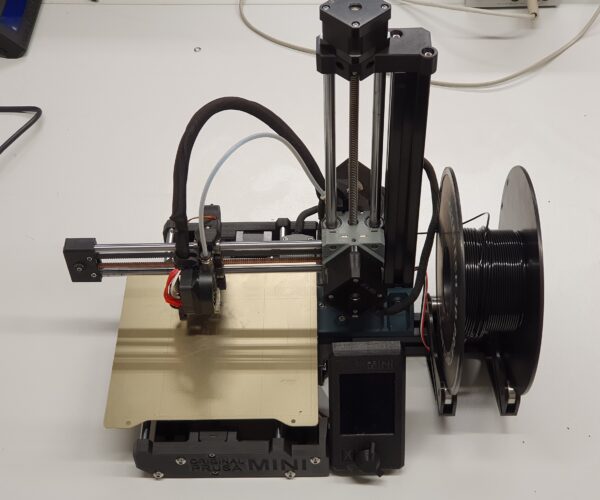

So I made minor adjustments and tried out the next version with 200mm 3030-Extrusion, as you can see here:

And this is the thing I was looking for.

Even now the Z-platte is still printed (not out of aluminium) the whole Z-Axis is very stiff and rigid and I am able to adjust the skew to make the X- and Y-Axis rectangular to each other.

This is how the current set up is looking now:

The benefits are a much more rigid Z-Axis, elimination of the X/Y-skew, space for a spool holder without putting load on the main construction.

(There are some designs which are putting the spool on this wobbly Z-axi... oh boys...)

And this design is cheap:

- 200mm 3030-extrusion cost about 10€ with shipping

- corner joint for 3030-extrusion about max. 2€

- few screws, hammer nut

To be honest: The placing of the fila-sensor is not optimal because I am not using it.

Maybe someone has a nice idea how and where to mount the fila-sensor.

I will do a bit of optimising to make the z-platte nice to print and post it here to download.

Kindly regards.

RE: My attempt to make the Z-Axis more rigid

Have you thought about this?

https://www.prusaprinters.org/prints/42318-prusa-mini-z-axis-support-strut-v2

--------------------

Chuck H

3D Printer Review Blog

RE: My attempt to make the Z-Axis more rigid

@cwbullet

The braces are good but you need a not twisted printer first.

Yes, indeed my solution is printed, too. But this is only at the moment and more a prototype.

I am still waiting for my aluminium-platte.

I printed my "prototype"-Z-platte on my MK2s Zaribo Mod, so this part will be rectangular enough 🙃

RE: My attempt to make the Z-Axis more rigid

@p-stock

Twisted Printer? Any relation to Twisted Sister?

--------------------

Chuck H

3D Printer Review Blog

RE: My attempt to make the Z-Axis more rigid

@p-stock

Twisted Printer? Any relation to Twisted Sister?

🤣

Sry or my english, as you may noticed unfortunately this is not my native language.

Here you do have a example of this what I was speaking about:

Kindly regards

RE: My attempt to make the Z-Axis more rigid

A suggestion for the filament sensor is to mount it on a sea-saw (spelling) hinge to allow it to move up/down with retractions and buildheight.

PLacement of the filament more towards the front, maybe resting on the table, could also help with alignment.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: My attempt to make the Z-Axis more rigid

@p-stock

Understand now.

--------------------

Chuck H

3D Printer Review Blog

RE: My attempt to make the Z-Axis more rigid

Would this be of help with filament sensor?

https://www.prusaprinters.org/prints/24951-prusa-mini-filament-sensor-holder-v2

RE: My attempt to make the Z-Axis more rigid

Dear P.Stock,

"I will do a bit of optimising to make the z-platte nice to print and post it here to download."

Respectfully ask, is your draft already available?

Unfortunately, I am also struggling with a z banding problem and have not found a solution so far.

Thank you in advance!

Daniel

RE: My attempt to make the Z-Axis more rigid

I had issues with the Z-axis flexing so added a support on the far side and then solid support legs directly to the existing 3030. This has pretty much fixed my issues. This didn't require disassembly of the Z-axis and although not as fancy it does work well.

https://www.prusaprinters.org/prints/40128-prusa-mini-xz-support

https://www.prusaprinters.org/prints/53953-prusa-mini-support-legs

RE: My attempt to make the Z-Axis more rigid

@bdaboy

Hi, this is a good idea indeed but does not remove a twisted XY-Axis.

@D3nkis

Yeah, next very few days I will do post everything.

As can be seen here, I could get rid of the twist in the XY-Axis an make near to perfect squared things.

All files will be online soon on this weekend.

I do know, this modification is not for everyone because is need a bit of work and new extrusion part.

RE: My attempt to make the Z-Axis more rigid

@p-stock

It's a great news. I can't wait for it 🙂

RE: My attempt to make the Z-Axis more rigid

@p-stock

where do you get the 30x30 aluminium Profile from and which type is it ? I wanted as well to improve the stability of the fixtation of the Z Axis to the Y frame, but could not find the information what alumium system has been used. I think it makes sense to make that that connection stiffer before spending much time in optimizing a skew, because more stiffness should minimize dynamic deviations (I was really surprised when I realized how weak effort is sufficient to move the X axis in Y or in Z).

RE: My attempt to make the Z-Axis more rigid

@kai-3

I got my extrusion from eBay (Germany).

Is a Bosch-Type 8mm T-Slott.

The files are available here: https://www.prusaprinters.org/prints/58842-prusa-mini-z-axis-modification