Must do: Hardware upgrades, why?!?

Hi guys,

I'm having some hard time to decide which printer is the right one, and no less important hardware upgrades needed.

For what is worth it, I have an Ender3-V2 with few upgrades in place.

So:

- it will work out of the box but it cannot print TPU. For AUD1k you expect the printer to have no issues. My cheap Ender can print TPU without problems

- extruder flaw: to solve the problem above and other issues related to it, users install a BMG

- the stock cooling doesn't have the best efficiency either. If you need a lot of bridging, things seem to be disappointing. I believe there's upgrades to be printed

- hotend flaw: it will work out of the box but you will have coggled nozzle for numerous reasons you can find online

- there are some very light direct drive to replace the BMG and solve both issues

- Firmware: Hardware upgrades require gcode changes which cannot be applied via firmware, only via slicer or "printing" the gcode. This restriction seems so wrong taking into consideration the money you spent on it.

Those are the main problems I see and shouldn't be there due to its price. These are operational issues/flaws which will affect the printer.

Again, it will work out of the box but you you wanna more advanced models, is where you start having problems. Is there anything else I should do to have a good experience with no headaches?

Is Prusa working on those issues to make it worth the money you spent on it???

Thank you

If I had my choice again I'd get the Mk3 over the mini

Hey mate,

I have a highly modified Ender and wanted a reliable workhorse so I could continue to develop it. Always wanted to try a Prusa so the Mini looked like a good fit.

I've had the Mini + for about 3 weeks and have had quite a bit of trouble with it. It's not been the experience I'd had hoped for.

Got the standard heat break clog and extruder binding that's been well documented.

I've since got over those issues and it prints PLA quite nicely now. In comparison to the Ender the Mini is far more dimensionally accurate with PLA with a much better finish.

However forget PETG on the Mini, the stringing on the current Mini bowden setup is impossible to dial out. The Ender does a better job with PETG.

I will note that the heat brake mod is not necessary and I've had worse results with it. Move the wires out of the way of the heat sink fan to increase the airflow, apply a better quality heat paste and get the heat break further up into the heatsink. Ensure the PFTE tube to protrudes out the top by a few mm rather than make it flush as per Prusa's instructions. This allows the brass coupling to put more little more positive pressure on the PFTE tube and stops the cloggs forming at the hot end.

Not being able to save to the EPROM also is quite disappointing. PID tuning and then entering in the results into the slicer is average. Knowing the extruder change would mean another thing to add as well.

Extruder has been better once I pulled it apart 6 times and found that leaving the hardware loose allows the filament tension-er to work. It was assembled to tight and allowed the filament to be ground down and then clog the extruder. The extruder looks to be where they reduced the cost too much.

If the Mk3 had a 32 bit board and I had my choice again I'd get the Mk3 over the mini.

If they enable saving to EPROM function and the bond-tech extruder fixes the PETG stringing, the mini could be the perfect printer but not yet.

If you only print PLA it's pretty good now.

Same boat

It's not been the experience I'd had hoped for.

This has been my issue.

I have an Ender3 V2 with few upgrades:

- z-axis stabilizer

- metal extruder

- Bullseye fan housing

- chep hotend fix (capricorn)

- PEI sheet magnet bed

I have printed PLA+ as usual, TPU and PETG, 70-degree angle without the support and great bridging support using the stock fan.

The more I read about Mini+, the less I wanna buy it really 🙁

As I mentioned in the post out of the box I cannot print TPU which is a big WTF!

Importing to Australia will be around AUD1K which is a lot of money.

I see people commenting that it works out of the box, but they are printing standard models which doesn't require much.

If you wanna print more advanced models, forget about it. Respectful Tech Youtubers have reported the same issues.

I wanted a Prusa to stop the endless tweaking with Ender but the tweaking only gets more expensive 🙁

I have asked this same question in the MK3S+ group. It will be around AUD1.5-2k to import it to Australia and it also has design flaws that require extra money with upgrades to get it right 🙁

I think I will spend half of the money I would spend with a Mini+ to buy upgrades to the Ender.

I am hoping to find users like you who shares the actual problems rather than "it works out of the box".

Thanks a lot.

My experience using PRUSA MINI+

I want to share my experience using prusa mini+ (well honestly YES it is works out of the box, until one month later and finally clogged).

I start in 3d print from feb 2021, i don't have ender, my first 3d printer is mini+. And from what i learn, the basic problem on my mini+ is the thermal paste on the heatbreak. (there is only a small amount of thermal paste on the heatbreak from the factory) so heat will travel and melt down the PTFE tube.

My mini+ clogged in the first month when i switch from PLA to PETG, in just one week print with PETG it and jammed, i try to look any tutorial but still clogged, i change the PTFE tube with capricorn but still clogged... then i try to re-apply the thermal paste using thermal grizzly kryonaut (i never read any tutorial on the internet about this), since then i never find any sign of clogged/jam anymore... even now i'm using cheap $1 PTFE tube, and often change filament from PLA to PETG vice versa without cold pull and never clogged.

Print TPU (SUNLU) using prusaslicer flex preset, never get any problem, with eSUN PETG i get the best settings (less stringy, best layer adhesion) at 220C and 2mm retraction. Until now my mini+ is 98% stock original, the parts i have changed is only PTFE tube (cheap one) and thermal paste (thermal grizzly kryonaut).

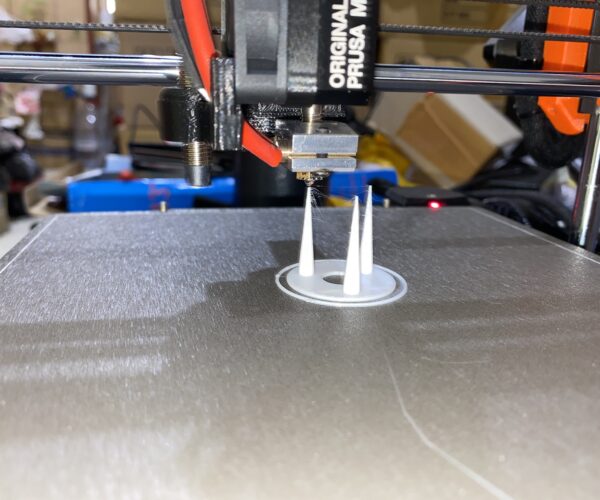

pic attached : white object is eSUN PETG

and black object is SUNLU TPU

@ratolloko

I'm curious... It looks like you have an upgraded Ender you're quite happy with. Why are you looking at Mini? It seems you watched Mini's reviews and so you're more or less familiar with it's positives and negatives. Some say Mini is better (than Ender), some say is not worth the money, some say it works out of the box and some say it doesn't, etc -and all that is true! It depends on user expectation, skill, experience and needs.

No matter what "other" say, if you buy Mini, then you'll have two average printers and nothing more. Or you can sell Ender and buy MK3S or similar printer in that price range. Then you'll have one better printer -I prefer to say "more versatile" printer. Yes, MK3S is kinda outdated by having 8-bit board.. still, it does better job than most 32-bit printers up to 500€.

I have Mini+, which was my first and still is the only printer. After reading reviews, I upgraded to Bondtech heatbreak & extruder during the assembly -the only change I've made. And it does the job as I expected. Was it too expensive? Hell, yes -it always is 😐 .

[Mini+] [MK3S+BEAR]

Your pricing is a bit off.

Your pricing is a bit off it's about,

$650 AUD for the mini.

$1160 AUD for the Mk3S+ (additional $200 for tax, gst and import fees)

Use pay-pal and pay with your banks conversion rate to get a little better deal. (bank fees depending)

It's not been the experience I'd had hoped for.

Importing to Australia will be around AUD1K which is a lot of money.

I have asked this same question in the MK3S+ group. It will be around AUD1.5-2k to import it to Australia and it also has design flaws that require extra money with upgrades to get it right 🙁

I can honestly say despite enjoying my tinkering with the Ender, the Prusa mini prints way better. If it wasn't for the poor PETG performance it's a very good deal.

I'm closing in on $800 AUD with the Ender modifications and it's not guaranteed to be any better than a Mk3 or even a Mk2.

I think I'll be on the look out for a Mk3 for my next addition.

thermal paste

then i try to re-apply the thermal paste using thermal grizzly kryonaut

@sandysasmita thanks a lot for sharing your experience. I've heard this issue related to the stock thermal paste.

The thermal paste you mentioned, is a high standard paste for CPU focused in the overclocking community, that might explain why.

I have that very same TPU, yours look just gorgeous, holy f.

it is complicated

It looks like you have an upgraded Ender you're quite happy with. Why are you looking at Mini?

Yes, I did a few upgrades but there is always something to tweak around, a z-axis line that appeared from nowhere in the model for example. I am tired of the endless tweaking.

I was in love with Mini+ because it seemed so problems free, assemble and voila. But the more I read the more I get disappointed.

I don't wanna a print to print cute things, cube and 3DBenchy only. I just started to design and print in 3D so I wanna be able to use the printer.

Ender is an awesome printer for you to learn how a 3D printer works, and you really do believe me.

You have this freedom, Prusa you cannot save the new extruder value in the firmware which is a big WTF?!

So the question "Why are you looking at Mini" is more like "I am not so sure anymore"

I looked at the big one but the same happens, if you actually explore the printer, you will have problems with extrusion and so on.

My conflict is the money you spent should give you a problems free printer, not really. I am lost.

RE: Thermal paste alone won't fix an incorrectly set up PETG tube

Just keep in mind it's two fold, thermal paste alone won't fix an incorrectly set up PETG tube.

Arctic silver or any CPU thermal paste will suffice for this application. Just my opinion grizzly kryonaut would be a bit of a waste on this application, you also get very little of it.

Also route those cables away from the heat sink fan. Makes a world of difference.

3D Printing is still a tinker hobby. You can't get set and forget, well not yet anyway.

Yes indeed.

Just keep in mind it's two fold, thermal paste alone won't fix an incorrectly set up PETG tube.

Arctic silver or any CPU thermal paste will suffice for this application. Just my opinion grizzly kryonaut would be a bit of a waste on this application, you also get very little of it.

Also route those cables away from the heat sink fan. Makes a world of difference.

Agree with you Nick! Every brand PETG have different settings. Not all PETG are the same.

About thermal paste, well at that time as a newbie i'm very stressed about how to fix that issue 😖 , so i'm looking on the internet and find a boron nitride paste, but that is not available in my country and i want to solved the problem ASAP, so i try to look the best alternative and find that thermal grizzly kryonaut are the best choice for me... and yes i get very little amount of it and it is very expensive, but i don't have any experience about 3d printer before, and i don't have infrared thermometer to measure the temperature at the heatbreak, so i choose that paste and hope for the best.

i will try to route the cable as you said, thank for the tip! 🙂

not really

Your pricing is a bit off it's about,

$650 AUD for the mini.

$1160 AUD for the Mk3S+ (additional $200 for tax, gst and import fees)

I am taking into consideration the upgrades I will need in order to have the printer doing what my Ender does, functionality speaking.

MK3S+:

- BMG extruder: The stock one is know for eating the filament and being terrible to clean. Design flaw. $$$ involved

- Direct driver: I need to find among my notes that its direct-drive will give you a hard time and an upgrade might be needed

Mini+:

- BMG extruder: Same as above $$$ or buy BMG parts which are cheaper than the whole BMG, print a housing and install a NEMA14

- Hotend issue: Upgraded needed

My Ender didi cost me AUD382.00 + AUD200 tops with upgrades to do what I do, sure, endless tweaking but it does.

Mini Plus + Upgrades are too much money for the headaches I didn't expect.

I am asking you guys ( the community) to understand the real problem and decide if I should wait for Prusa to improve the printer quality or forget about it altogether.

Agreed but...

3D Printing is still a tinker hobby. You can't get set and forget, well not yet anyway.

No doubt. If you have an Ender, today everything is fine but tomorrow, well. You have a Z line here, something off there.

Prusa "as the ADs say" it just work and work so I was happy to spend the extra money. Well, that is not quite right.

Being unable to print a basic material like TPU, extrusion issues because of a design flaw, coggled nozzle coz design flaw, use workaround because you cannot save the new extruder value in the firmware aren't the things you wanted from an "it just work and work".

Or I am doing research in the wrong places or Prusa users without problems only print PLA and basic models which don't stress the printer like bridging.

RE: Contex and user needs change the recomendaion.

I think you have a few things to nail down before you can make the call and remember many, myself included, can be wrong and give false accounts.

What's your intended use and build volume needs?

what fillaments do you need to print vs want to print?

Do you need more than one printer?

A Bowden setup it was always going to have a hard time with some filaments, flexible's in general are a not going to go well.

I've got the Mini working exceptionally well with PLA and ok with PETG all with stock items no additional parts were needed. It did however need some carefull assembly to make it work. I think they are really under the pump with the popularity of this model and are throwing them together so fast a few QC issues are happening.

The dual geared extruder may be required to help the PETG performance but that's yet to be confirmed by myself yet. I'm also working though other PETG manufactures that have proved to be better and worse.

I can confirm the heat break, sock and heater block have all been tried on my Mini with no better quality, worse in most cases. Also comes with the additional issue with slicer settings.

Also remember $1500 for a 3d printers quite cheap, they were 3-4K before Prusa. Now others have copied their design we have a warped sense of value now.

The Mini is leagues ahead over the stock Ender I started with. Not perfect sadly but it's got more right than wrong.

Fresh start perhaps...

The Mini is leagues ahead over the stock Ender I started with. Not perfect sadly but it's got more right than wrong.

Thanks a lot for your sincere point of view.

I believe my problem is because I already have one printer, I already had the most common problems and learned a lot from it so it's natural for me to see the problems right away.

If I was starting now into this hobby, totally newbie, I would be happy with Prusa Mini+ as it is.

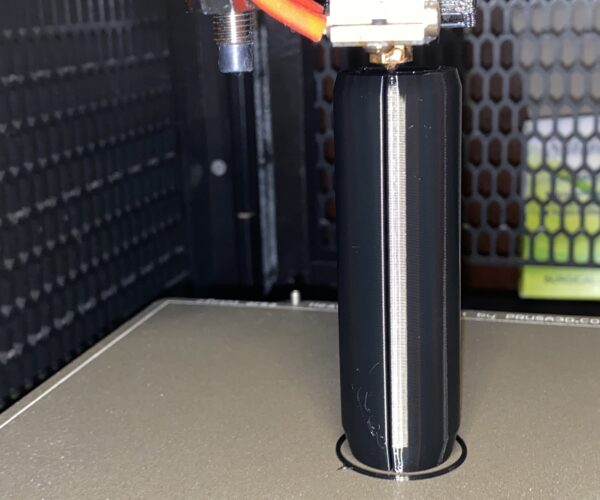

RE: This should illustrate the point a little.

This should illustrate the point a little, Same filament.

Refer - Attached Image - Left is the Mini, Right is the Ender.

Ender;

Linear rails, Dual Z axis, SKR 1.4 Turbo, 2209 steppers + much more but still runs the same stepper motors, hot-end, extruder and bowden tube.

Mini+,

Stock.

The Ender print was done stupid fast as I was trying to introduce stringing.

The Mini has a much nicer finish but strings though all temps.

Note - It's not a perfect comparison as the Ender profile in PrusaSlicer does not work on this Ender configuration so was sliced in cura.

My final thoughts about this ..trying to point you in right direction -and I'm not try to sell you a Mini.

If comparing both stock, Mini is better than Ender (I think that's common agreement). But as Ender is cheaper, one is ready to accept that and sees both printers as equally good/bad -which is not true. Mini is to begin with better. Mini only "needs" two upgrades (heatbreak=17€ & extruder=70€) and you're ready to go -no tinkering. How many upgrades Ender needs? And even then, it will only maybe match Mini.

TPU... If I say, you can print it with Mini, then that's only half of information. Because it depends on filament shore hardness and it depends on what you wish to print. Every bowden type printer is limited in this regard and if detailed TPU prints (with a lot of retractions) are your priority, then you need printer with direct drive extruder.

And finally, you can save extruder & heatbreak values into Mini's firmware -is open source as so you can modify it at will. The only downside is, if you wish to load modified firmware, you lose warranty. For me personally, that was no big deal though -but is still a big minus for Prusa in my eyes.

Would you be more happy with Mini than with Ender? Hard to say... is a lot of money to pay for "a bit better" printer -especially if upgraded Ender does the job for you (more or less).

[Mini+] [MK3S+BEAR]

Prusas

Is Prusa working on those issues to make it worth the money you spent on it???

Thank you

My Prusas are well worth the money spent with zero modifications. I own 8 Mk3S and 5 Minis. I own an Ender 3 and CR10 S Pro and would not pay a dime for another one. Pure garbage compared to the Prusas. I realized some folks get lemons, but I see far less with Prusas.

Just one users view.

--------------------

Chuck H

3D Printer Review Blog

RE: Work for Me in Stock Configuration

Is Prusa working on those issues to make it worth the money you spent on it???

Thank you

My Prusas are well worth the money spent with zero modifications. I own 8 Mk3S and 5 Minis. I own an Ender 3 and CR10 S Pro and would not pay a dime for another one. Pure garbage compared to the Prusas. I realized some folks get lemons, but I see far less with Prusas.

Just one users view.

I'm going to agree on the Mini. I don't have much experience with other printers. I used my Mini for a year, bone stock, printing 16 hours a day, going through dozens of rolls of filament, for months, with PETG and ASA and it worked fine with appropriate attention that all printers need. After a year the hot end PTFE tube wore out and due to my inexperience trying other things I had to rebuild the hot end. I got new hot end parts from Prusa and put them together as the guides said and it is working again, at least as well as before. I did add a silicone sock to keep the hot end from getting munged up.

No, it is not perfect, and it takes some attention and experience to run, but upgrades are not a "Must", or there would not lots of them that are working just fine. You just don't have many posting to forums when they have no complaints.

I've found the best "upgrade" to better printing is to dry my filament.

Regards,

Mark

...

but upgrades are not a "Must", or there would not lots of them that are working just fine. You just don't have many posting to forums when they have no complaints.

I guess this comes to my personal opinion, as it isn't a "cheap" printer on my currency, I had higher expectations with no need to do basic upgrades or extra care. I realised that now.

I've found the best "upgrade" to better printing is to dry my filament.

Same, I have a basic Creality dryer and leaving it on for hours or leaving it on during long printing leaves the skin so smooth. Some models look like it was made from a mold/cast.

Thank you

Hi guys,

First of all, thank you so much for all the help, thank you for sharing your experience.

I believe that right now I have a better understanding of what to expect with Mini+, what issues I might have or might not and how to solve them or even prevent them.

I am tagging this post as "Solved"

Thanks a lot.