Mini Y Axis Endplates - Strength?

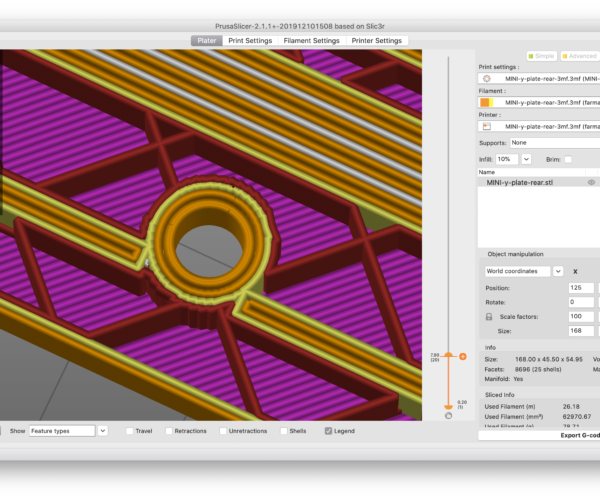

Has anyone downloaded and sliced the Mini Y axis endplates yet? I looked at them yesterday and they have really lightweight internal supports of 10% only. Also looking at the 3mf file they appear to be printed with .60 nozzle?

I am quite surprised at these seeming so apparently lightweight - surely they are a structural part?

RE: Mini Y Axis Endplates - Strength?

i am gona print tonight first mini parts. maybe i can say then more.

but strenght is more given throug perimeters than infil. how much perimeters do they have?

RE: Mini Y Axis Endplates - Strength?

Only had a quick look but it appeared to be two

RE: Mini Y Axis Endplates - Strength?

If it is using a 0.6 nozzle then thats equivalent to 3 perimeters from a 0.4 anyway. On my printer with 0.6 I normally drop from 3 to 2 and parts are plenty strong enough. Also that area might not be subject to huge forces anyway.

RE: Mini Y Axis Endplates - Strength?

@neophyl

Y belt tensioning is usually there.

RE: Mini Y Axis Endplates - Strength?

Yes the belt tension is but if you are tensioning your belts that tightly then you are risking damage and stretching of the belts themselves. Cant remember the values Tim mentioned that the steppers are supposed to max out with sideways torque but it isn't a huge amount and a printed panel of that size with the infill at the angle it is shouldn't have a problem.

RE: Mini Y Axis Endplates - Strength?

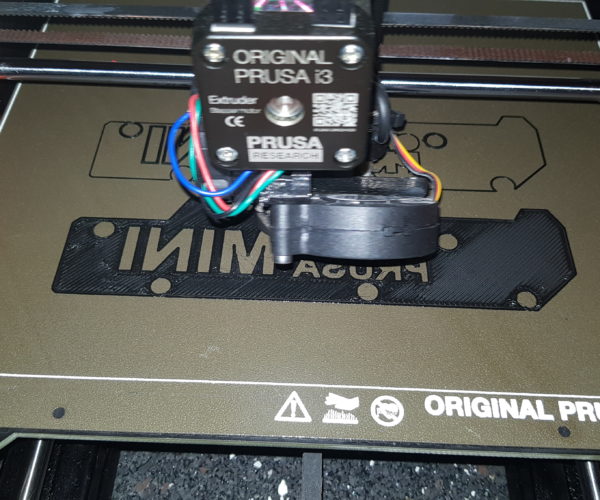

This goes below the metal plate?

RE: Mini Y Axis Endplates - Strength?

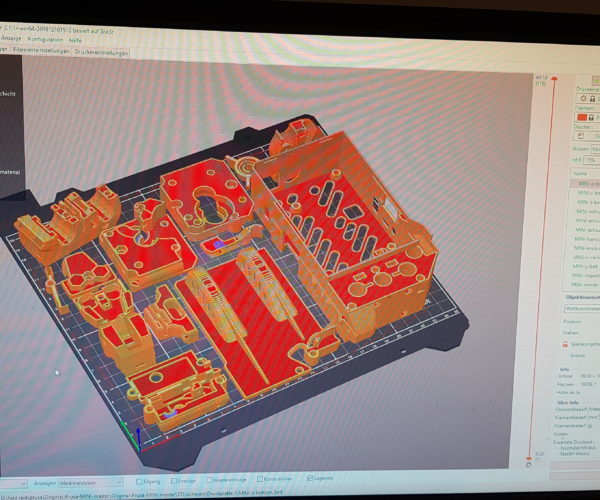

but i have to reprint it. Layer shift.... but its enourmous strudy. They reinforxed it with massive infill sections

but i have to reprint it. Layer shift.... but its enourmous strudy. They reinforxed it with massive infill sections

RE: Mini Y Axis Endplates - Strength?

Wonder what the front plate would look like with the the first layer(s) in orange - so black lettering showing through... hmmm...

RE: Mini Y Axis Endplates - Strength?

Really like the 2 colour print Pingu, also those extra interior sections look like the result of some stress analysis to determine where it needed the extra stiffness. Seeing that I don't have any reservations about it being up to the job (not that I had any before anyway).

If you look at the whole MKx series it was designed to trim costs where it could without compromising the core areas. A lot of people complained about printed parts but look at history, it works. So I'd fully expect that philosophy to carry on with the mini. I'd imagine that there was a lot of design iterations before getting to what we see today.

RE: Mini Y Axis Endplates - Strength?

it is very study. because its failprint (layershift) i tried to break the parts in the morning. no way!

i tried it on a table edge in the middle of the part and my full weight and muscle force on the very ends of the parts for maximum lever force.

not shure if i managed to even bent it a little... VERY studdy part.

by the way, anyone any idea why i get ocasionaly layershifts? this time it was on the X axis... retensioned the belts about a month ago because of layershifts on y axis. the last 4 days i printed over 10 hour parts, one per day, no problems. and with tense gyorid patern... now retringular patern and problems... dont get the problem

RE: Mini Y Axis Endplates - Strength?

I see it near the top of the print. Id actually remove the belt(s) and check the axis in question moves freely in both directions as a starting point.

Next I would check the gears grub/set screws to make absolutely sure that its 100% against the flat of the stepper shaft. Belts should be taut but not tight. Ok not the best description I know but I usually just go by feel as I'm quite used to machinery. I do know that you can over tighten them and that actually puts more friction into the system which can then lead to binding (with bearings sticking). Which then leads to shifts etc.

Tim is probably the most knowledgeable in this area.

RE: Mini Y Axis Endplates - Strength?

Where can I find the 3mf files for the Mini parts?

At GitHub I can find the parts, but not the 3mf files. Asking support they just told me to use standard settings in PrusaSlicer for Prusa PETG.

Have a look at my models on Printables.com 😉