Mini - Built In Bowden Issues? Design Issue?

So my Mini lasted around an hour before the control knob failed while calibrating the live z, but during that short period I experienced some difficulty in loading filament and getting consistent flow. From other posts it seems other are suffering filament feed issues so as I can't use my Mini until Jan 30th (Thanks Prusa, Xmas, UPS) I thought I'd look a little deeper.

When I dismantled the Bowden I found a section of filament inside it stuck in the hotend and PTFE. I heated up to temp and manually removed it. What I found may explain some of the filament issues.

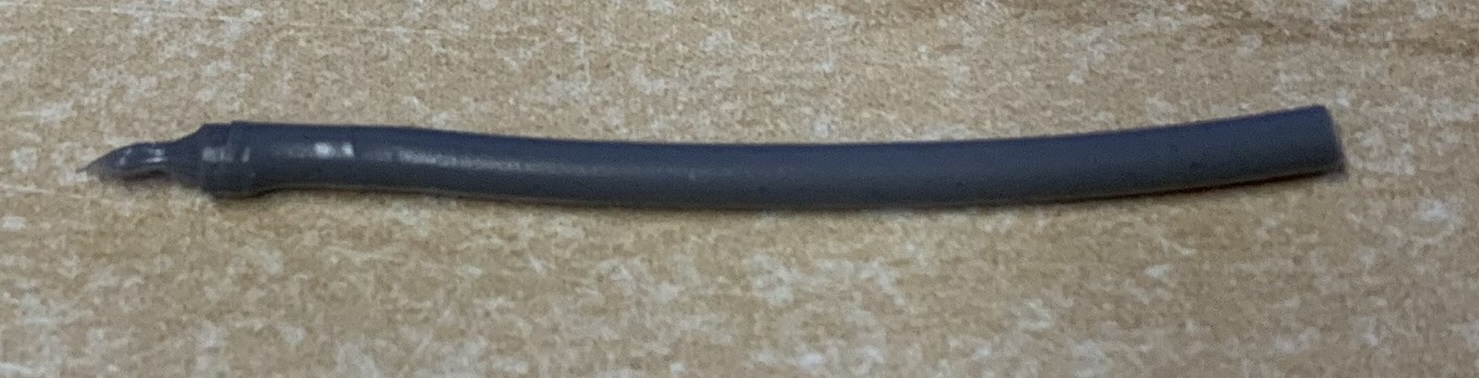

As you can see there is a bulge from inside the hotend. This bulge measures 2.02mm - 2.06mm in diameter.

Measuring the Bowden PTFE the maximum I can get is 1.96mm ID. This is at the end, before the brass fitting constrict the tube further. A plain piece of 1.75mm filament passes through the tube without issue as you would expect but a distinct restriction can be felt past the two brass olives. I would estimate the ID there is down to 1.80mm - 1.85mm. There is no way the blob will pass even the end of the PTFE let alone the restricted areas.

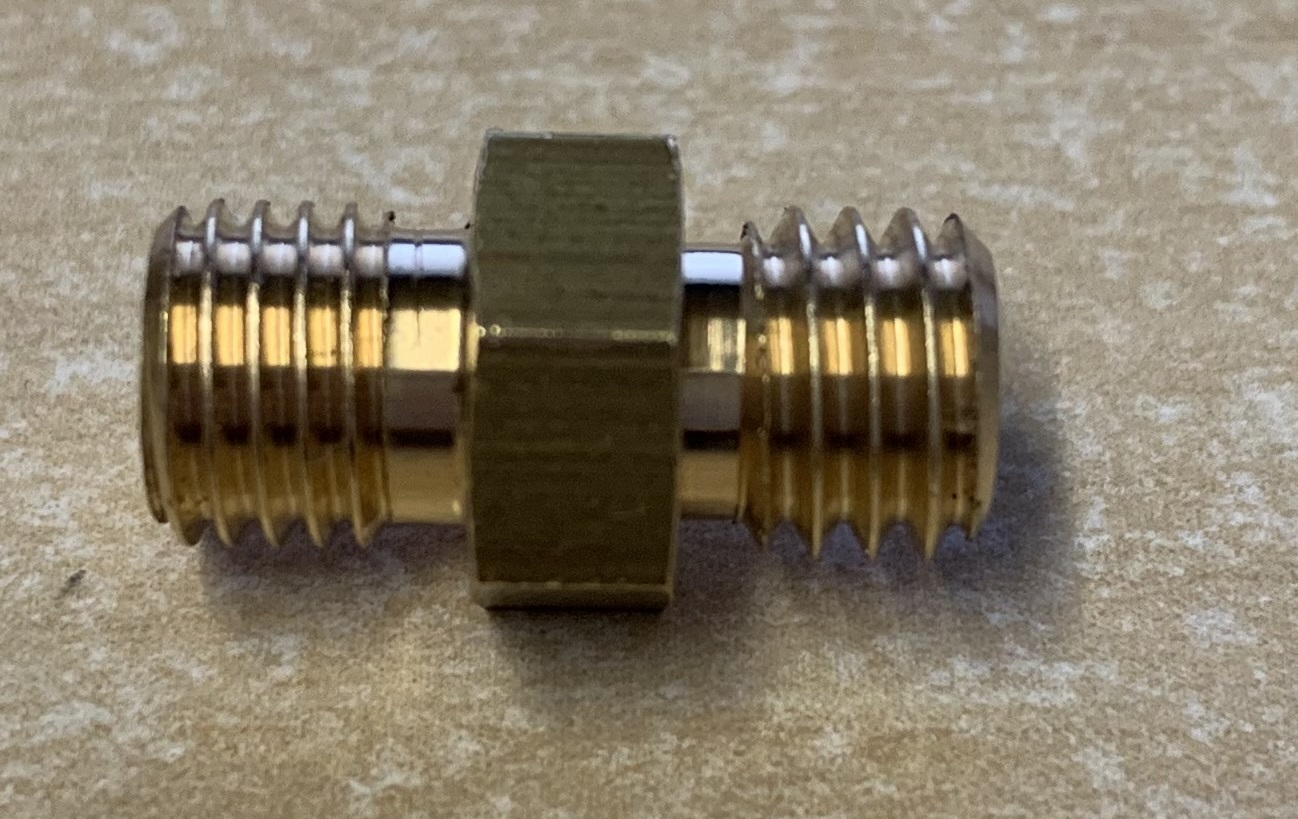

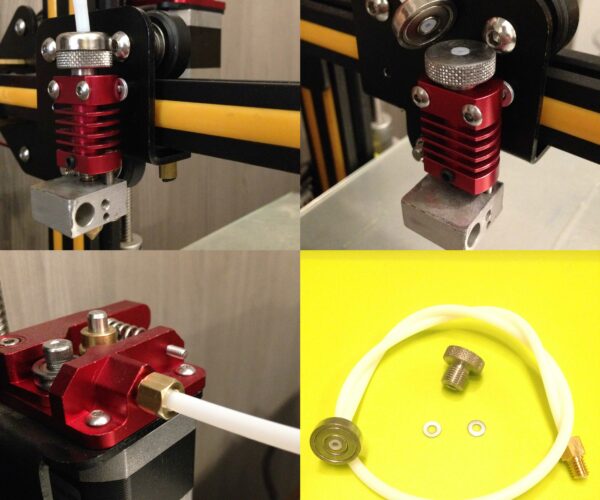

I decided to try festo's, and some of the 4mm OD x 2.5mm ID PTFE I bought for the MMU2S. The couple of different sized festo's I have in stock are nothing like the thread in the Mini. The fitting in the x carriage heatsink is a standard M/M brass adapter but the two threads differ. On the heatsink end (RH in the pic) the thread is quite coarse, and the brass nut end is finer.

Q. - Has anyone found a festo that will fit yet?

Finally, when removing the stuck filament from the PTFE I found a section that had been chewed up by the extruder. It was the extra diameter of this section that was jamming the filament in the PTFE and I had to use some force to withdraw it, especially past the brass olive. The filament I was using was a generic Amazon PLA that I have been printing with successfully with Mk3S's for some time.

RE: Mini - Built In Bowden Issues? Design Issue?

The fine thread on the brass nut side of the adaptor appears to be M8x1.0

RE: Mini - Built In Bowden Issues? Design Issue?

I decided to try festo's, and some of the 4mm OD x 2.5mm ID PTFE I bought for the MMU2S. The couple of different sized festo's I have in stock are nothing like the thread in the Mini. The fitting in the x carriage heatsink is a standard M/M brass adapter but the two threads differ. On the heatsink end (RH in the pic) the thread is quite coarse, and the brass nut end is finer.

...

Q. - Has anyone found a festo that will fit yet?

Festo goes up to M7x1.00 threads; the larger ones are all G/BSPP.

RE: Mini - Built In Bowden Issues? Design Issue?

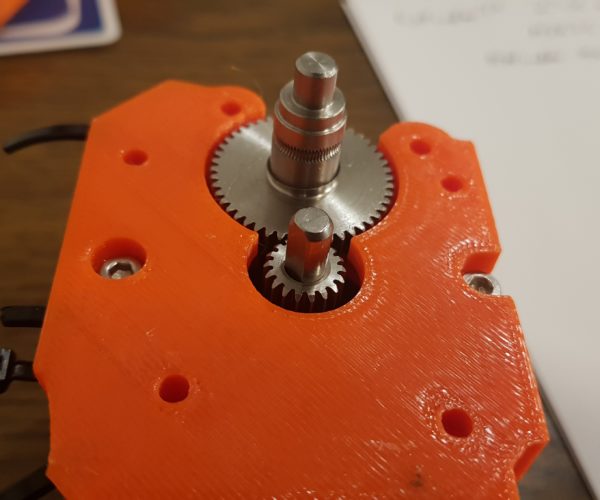

I have very similar issues. I’ve dismantled the entire extruder and can’t see exactly where my issues lie. I did see a small strand of orange filament from the extruder in the Bowden tube to the hot end, removed that to no avail.

I actually think my extruder is missing steps and this is causing the hobbed nut to chew up filament as I try tensioning the idler, creating bulges and jams, and compounding the issue.

I am waiting on Prusa support to return from their break and will see what they say.

RE: Mini - Built In Bowden Issues? Design Issue?

probably experiencing the same issue here. i started noticing when i unload filament it often gets stuck and i have to pull hard to get it out. after i find shreds of filament everywhere..

RE: Mini - Built In Bowden Issues? Design Issue?

Have that problem too. It is like the end (hot end) of the filament has a to big diameter and has a hard time getting through the PTFE tube when unloading.

Have a look at my models on Printables.com 😉

RE: Mini - Built In Bowden Issues? Design Issue?

I also ran into this problem on my first print, the prusa logo and I was very frustrated. After taking apart and pulling out a totally malformed string of filament, the situation is much better now. It sometimes sounds like the extruder gear is making some very strange noise, but it actually prints and no noticeable defects in the prints. I kinda glad that other also suffer from this problem, so it is more common.

RE: Mini - Built In Bowden Issues? Design Issue?

I have similar feed problems. All will be well and then the hobbed gear springs back about a quarter of a turn, with a very distinctive noise. It's almost as if the pressure in the nozzle end is too much and the filament pushes back. Initial prints were fine but this problem is causing noticeable under extrusion.

RE: Mini - Built In Bowden Issues? Design Issue?

@jockspice

Check out the “under extrusion” topic. Some of us have found that the hot end (three screws) that secure the heat break etc are not tight. This caused under extrusion for us and when tightened it resolves the issue. Not sure if you are seeing similar issues but worth checking.

RE: Mini - Built In Bowden Issues? Design Issue?

i had several times also malfunction during unloading filament.

it was the same szenario every time: the unloaded previous molten filament tip was too thick for either the couplings or the ptfe tube.

the extruder gear scraped filament off and when i took it apart the half diameter of filament was gone.

i was woundering since my first day when i did a complete teardown of the printer ehy they did not keeped dual extruder teethed gears like in the i3 series. i guess a secound teethed idler would make double torque possible during unload. not happy abput this design issue.

RE: Mini - Built In Bowden Issues? Design Issue?

i had several times also malfunction during unloading filament.

it was the same szenario every time: the unloaded previous molten filament tip was too thick for either the couplings or the ptfe tube.

the extruder gear scraped filament off and when i took it apart the half diameter of filament was gone.

i was woundering since my first day when i did a complete teardown of the printer ehy they did not keeped dual extruder teethed gears like in the i3 series. i guess a secound teethed idler would make double torque possible during unload. not happy abput this design issue.

RE: Mini - Built In Bowden Issues? Design Issue?

They didn't do dual gearing on the extruder?

This sounds a lot like my initial Ender 3 experience. It skipped so I turned up the temp to make it easier to push. It still skipped but a lot less. I put a dual gear extruder on it and now it consistently pushes/pulls the exact amount of filament even at lower but reasonable temps. The filament also has significantly less wear from the dual gears than the Prusa single gear is putting on the filament. The dual gearing made a huge difference in its ability to push filament out other end of the bowden tube and to pull blobs back out.

Dual gears are also a curse the way Prusa does their extruder designs because they can pull large blobs through the PTFE up to places in a direct drive setup where you can't easily remove them. The MKx's have done this to me before and created a nightmare to solve since the blob is trapped in the PTFE tub or in the heat break inside the extruder assembly. It seems like they should be able do dual gears and just detect excessive torque on retract and not pull it back too far, especially since they have a new board with enough memory.

I've had several malfunctions while unloading on the mini. In two of them, there was blob on the end of the filament that was just too large to enter the tube. It seemed like the filament had cooled this way and couldn't be moved forward or backward because of it. I measured the filament between the extruder and hot end and it was pretty close to 1.75mm so the end blob was the only issue I could see.

The other one I had the filament was stuck hard in the PTFE tube. I had to remove the tube completely and it took effort to pull out. I'm pretty sure the filament and tubing were just not compatible. This filament was 1.8 mm in diameter for most of the length and you could see there was little additional room in the bowden tube for it. I measured this one every cm or so looking for it to be out of spec but it was never over 1.8 mm. Based on that I'm guessing the tubing on mine can't be more than 1.85 mm inner diameter. What has me baffled with this one though, is the mini produced an amazing perfect 26 hour print with this same spool but the next print severely under-extruded and I got this jam trying to remove the filament after that to check it. So, it used to work, with the same spool, and maybe its just this part of the spool or maybe the extruder gear is loose now.

It would be nice to see some feedback from Prusa on what widths of filament were tested to know if it requires Prusament specs of no more than 1.77mm to work right or if there there is another issue.

RE: Mini - Built In Bowden Issues? Design Issue?

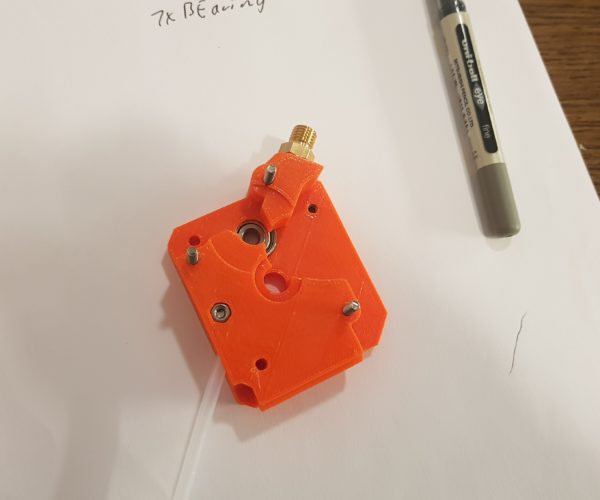

Want to try the Magnet MINI ?

I have already design this tips on other 3Dprinter. It's a brass part on extruder & a Magnet/steel part on Hotend with Capricorn Xs or Ptfe tubing.

It's very good, no one has more connector problems on theirs printers 😉

2 pictures & last on a printer to show

Contact me ,thx

RE: Mini - Built In Bowden Issues? Design Issue?

@olef

One side has a metric standard thread M8x1.25, the other side a metric fine thread M8x1.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.