How much bridging "drop" should be expected? Pic included.

Hi!

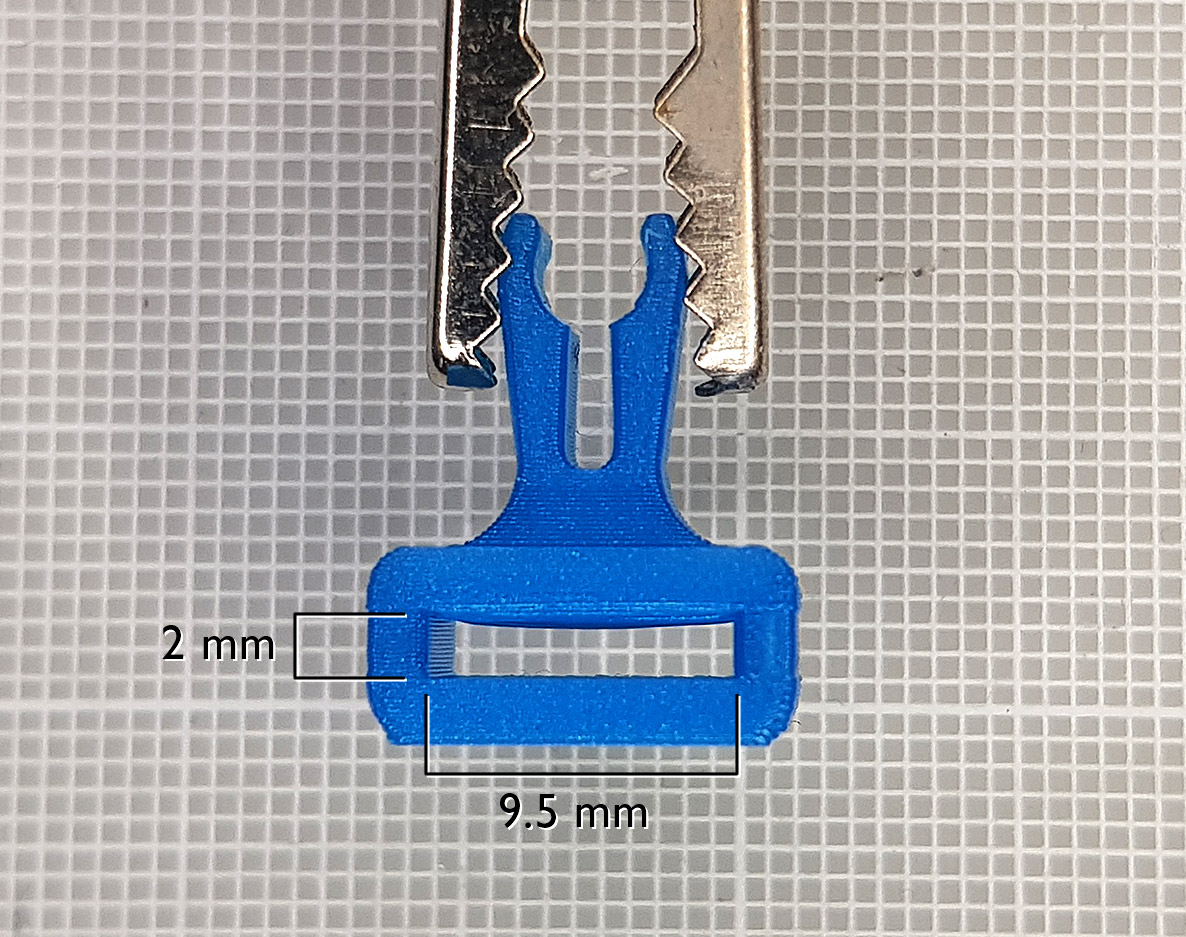

Been having a great time printing on my mini but so far I've mostly been printing objects that feature minimal to no overhang/bridging. I just now tried to do a print with a 9.5mm overhang and I'm getting about 0.3mm of drop. Is this to be expected? I printed the same print with supports and turned out perfect but I'm doing loads of these tiny things and removing supports takes time.

RE: How much bridging "drop" should be expected? Pic included.

Hi. Any reason not to print it in the same orientation like on the pic? Would prevent from any bridging issue for sure.

Anyway, try to tune cooling fan speed, bridging extrusion multiplier and moving feedrate during bridging to improve results. Maybe a slight drop of hot end temp could also help.

regards Jan

RE: How much bridging "drop" should be expected? Pic included.

Not sure what the thing is for, but it seems to me that the strength of it would be greatly improved, if you printed it on it's side.

The two parts next to the square hole are very weak if you pull something like a tie or a belt in that hole.

This will make the feed follow the shape and make it better for a pulling force in the square hole.

RE: How much bridging "drop" should be expected? Pic included.

It seems like a compromise. Ugly bridge/overhang droop or else ugly support interface. Pick the lesser evil.

One thing to be sure that you're doing is to be sure the 'Z contact distance' of supports is set to something like .25mm, as the default in prusaslicer is .1 mm, which is intended for soluble support. At .25mm the supports tend to break right off, but the lower layer under the support is never that clean looking.

RE: How much bridging "drop" should be expected? Pic included.

The only way to improve is if you play with speed, flow rate and also upgrade your cooling duct. Even though my prints are not so demanding at the moment I am trying to design a new fan duct for the Mini. Other than that... yeah I would also say that orientation plays major role but sometimes strengthwise you need to compromise.

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0

RE: How much bridging "drop" should be expected? Pic included.

Hi. Any reason not to print it in the same orientation like on the pic? Would prevent from any bridging issue for sure.

Anyway, try to tune cooling fan speed, bridging extrusion multiplier and moving feedrate during bridging to improve results. Maybe a slight drop of hot end temp could also help.

regards Jan

Picture doesn't show it but the "caliper" part that's clamped is centered so that would make an overhang issue instead of a bridge issue. Ah so manually playing around with settings then, might give it a try, maybe make a model just for different bridge lengths for more efficient results.

Not sure what the thing is for, but it seems to me that the strength of it would be greatly improved, if you printed it on it's side.

The two parts next to the square hole are very weak if you pull something like a tie or a belt in that hole.

This will make the feed follow the shape and make it better for a pulling force in the square hole.

The square hole are for popsicle-sticks so no real force is applied on the any of the walls. But yes I can see how anything with a curvature would be an issue.

It seems like a compromise. Ugly bridge/overhang droop or else ugly support interface. Pick the lesser evil.

One thing to be sure that you're doing is to be sure the 'Z contact distance' of supports is set to something like .25mm, as the default in prusaslicer is .1 mm, which is intended for soluble support. At .25mm the supports tend to break right off, but the lower layer under the support is never that clean looking.

Ah so I'm getting the feeling then that this sort of drop isn't unusual and I don't need to calibrate my printer. Oh that is a great tip because I printed with supports and I felt they were way too tight and difficult to remove. Had to use force to get them to unstick. Will definitely check that setting thanks!

The only way to improve is if you play with speed, flow rate and also upgrade your cooling duct. Even though my prints are not so demanding at the moment I am trying to design a new fan duct for the Mini. Other than that... yeah I would also say that orientation plays major role but sometimes strengthwise you need to compromise.

Gotcha. As mentioned above I might make or find some sort of test print just for bridging and play around with the settings to fine tune things in the future. For now I think I'll just try and get creative with design and orientation like so many of you have said.

Cheers guys!

RE: How much bridging "drop" should be expected? Pic included.

If you use Prusa Slicer, you can play with settings for speed and cooling for bridges. Speed is under Print Settings -> Speed, there's a speed value specifically for bridging. Fan speed is under Filament Settings -> Cooling -> Bridges fan speed.

Is this PLA or PETG? It looks more like PETG because PLA usually bridges quite nicely. PETG does not like bridging (it's less viscous and heavier than PLA), but try playing with fan speed and change it from default 50% on bridges to 80% for example.

You mentioned it's for popsicle sticks - is it asafety measure where you serve customers popsicles in holder instead of touching it with hands?

RE: How much bridging "drop" should be expected? Pic included.

@crawlerin

It's PLA.

I'm now also thinking my enclosure, even though it's open, might be a little too warm as well, it's been unusually warm weather during the past couple of weeks. Going to add a fan and see if that makes a difference before trying different settings.

No this is just for architecture models of triangular roof structures. But I like your idea 🙂

RE: How much bridging "drop" should be expected? Pic included.

@geoper2

Did you see the RHD fan duct modified for the Mini by Olof Ogland?

https://www.prusaprinters.org/prints/34475-prusa-mini-rhd-fan-duct-rev-c he's been posting prints to the FB group "Prusa Mini Users" about it. I haven't tried it yet, but am certainly curious about it.

RE: How much bridging "drop" should be expected? Pic included.

@mog

No I wasn't aware of that! Thanks for sharing I will have a look at it for sure!

Original Prusa Mini + Smooth PEI

Prusa Slicer 2.6.0