ABS Printing with the MINI+

Hello everyone!

I am currently wondering wether the Prusa Mini+ is able to print ABS within its entire printing volume. I want to order the Prusa Mini+ because the dimensions are absolutely perfect for my upcoming subjects I want to handle with the printer and one of them needs ABS. I have already read that the maximum bed temperture is 100°C and it is probably because of the limiting power of the power supply which may overheat. I was just wondering wether the Prusa Mini+ is able to achieve the necessary temperatures to print ABS. In their documentation it's stated that it's possible, but I want to be sure about that before I order the printer. Can anyone tell me if it's possible to print ABS in the entire printing volume of the printer when used in an enclosure?

Thank you very much in advance.

Cheers,

Keromida

RE: ABS Printing with the MINI+

I print almost exclusively these days in ASA on my mini, as long as you have a good enclosure and let it warm up before starting the print it should be fine.

RE: ABS Printing with the MINI+

Very much appreciated! Do you have a picture of the printquality?

RE: ABS Printing with the MINI+

What is the temperature in your enclosure while printing? Do you monitor it somehow?

RE:

I wouldn't recommend the mini at all. Especially not for printing filaments at hotter temperature (ABS: ca. 240 - 270, depending on the filament). Just check out the forums how many people have problems with heat creep and other hotend related issue. The hotend fan and fan duct are limiting factors too. There is a reason why you find so many upgrades for the mini that look basic. Another problem will be the stability and vibration: You can't print fast like on a i3. Keep that in mind in case you need to print prototypes or other things that need to be finished in a given time. If you check the forum you will probably also find out that many people started to have the problems after some months (not directly after getting the printer). If you buy a mini you have to be aware that the chances are to spend a lot of time and money to get it working for a longer time (as a workhorse).

I had to replace the hotend with a dragon hotend and added a 5V Noctua Fan with an external power source (FYI: The Fan is in the FW limited to 40%, so you need an external power source for more airflow). I also replaced the extruder (not directly related to ABS, just for information how I print ABS). Now I can print more or less any filament without a problem in an enclosure.

I hope that helps you on your decision

To your second question: Unfortunately I have no pictures of ABS (from eSun) prints at the moment.

Off topic: A good idea is to use a ventilation that transports the air from the enclosure outside of your room/house and/or to use a good filter (like the nevermore + hepa) because of the dangerous fumes from ABS.

RE: ABS Printing with the MINI+

Very much appreciated William! I actually was aware of the problem with the heat creep and the non-working / problematic extruder. I already bought the Bondtech Heatbreak and Extruder specifically for the mini. I also planned to use my Phoenix Contact 300W Quint4 passive cooled Power Supply with NFC onboard to monitor and regulate the output voltages. I don't need the Prusa Mini as a workhorse, I only need it for personal projects such as printing brackets for my Philips Hue smart light setup, electronic enclosures for my custom PCB's and for other things. The problems with vibration is actually not that difficult to solve. I don't know why people always have to hesitate the print and go for like 100mm/s as a printing speed. I personally print at aroung 50-60mm/s which is not really fast and even my horrific Tevo Tarantula was capable to print ASA with all the acrylic components. But to sum my post up, I want to thank you for the input William! It was a very informative experience for me!

RE: ABS Printing with the MINI+

Very much appreciated William! I actually was aware of the problem with the heat creep and the non-working / problematic extruder. I already bought the Bondtech Heatbreak and Extruder specifically for the mini. I also planned to use my Phoenix Contact 300W Quint4 passive cooled Power Supply with NFC onboard to monitor and regulate the output voltages. I don't need the Prusa Mini as a workhorse, I only need it for personal projects such as printing brackets for my Philips Hue smart light setup, electronic enclosures for my custom PCB's and for other things. The problems with vibration is actually not that difficult to solve. I don't know why people always have to hesitate the print and go for like 100mm/s as a printing speed. I personally print at aroung 50-60mm/s which is not really fast and even my horrific Tevo Tarantula was capable to print ASA with all the acrylic components. But to sum my post up, I want to thank you for the input William! It was a very informative experience for me!

You are welcome. Some additional information that may help you later:

I also started with the bondtech heatbreak and like many others I had new problems starting with it. Event he bondtech heatbreak doesn't solve the problem that over time the heat travels up and the airflow is not enough to cool it down on higher temperatures. If you stay with the original hotend maybe have a look on replacing the fan duct with one that optimizes airflow and get a hotend fan with an external power source (I have a Noctua 5V with an external USB power supply). Even if your enclosure is in optimal ambience (as I have), the hotend will get to hot over time (longer print duration and high temp filament). And when you are already replacing the heatbreak you can replace the PTFE tube with capricorn (just to be on the safe side that it wont shrink / or at least not so fast). In the end I replaced the hole hotend, that did the trick for me.

The vibration problem is combined with alignment issues: the whole Z-axis is attached with a PETG part (small area too) to the Y-Axis. This leads to problems that the X-Axis is not perfectly aligned (90degree angle) to the y-axis. This is of course solvable but still a questionable problem. All this issues are here since day 1 on the mini release and not addressed and therefore the user must solve them. If you are aware of all the problem that are unsolved, you are willing to thinker, spend a lot of additional money and not depending on the printer, give it a try 🙂

RE: ABS Printing with the MINI+

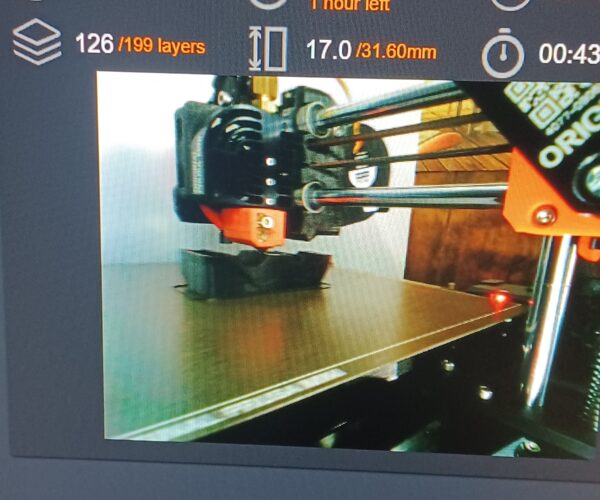

Hey OP, here's a photo of me currently printing with ABS+ with my Prusa Mini inside a Lack enclosure. Works absolutely fine and results are quite nice, though I did have to tweak the stock profile and increase parts cooling a little to get better overhangs. Not exactly the whole bed, but almost! Hope that helps.

RE: ABS Printing with the MINI+

Very much appreciated! May I ask at which temperatures you are currently printing?

RE: ABS Printing with the MINI+

Started at 240C but I found my overhangs actually getting burnt (turned yellowish-brown), so went down to 230C, then started increasing fan speed to about 40% after the first layer. I was worried about warping, but turns out it's a non-issue with this brand of filament I'm using with the smooth PEI sheet. I don't even need a brim (or glue stick), it just adheres like no tomorrow. The filament I'm using is Quinx ABS+ which is an in-house brand of a local store in my country.

Very different experience with eSun eASA. Definitely needed a brim, fans off, and print sheet cleaned with dish washing soap and IPA in between prints to avoid warping.

Haven't tried eSun ABS+ yet. I've heard that's easy to print with too, and I'll be trying those out soon.

RE:

Thank you very much. I'm planning on using Extrudr DuraPro ABS. At which heatbed temperature were you printing?

RE: ABS Printing with the MINI+

Oh I forgot to mention my bed temp! 100c, the highest the Mini can go, and what is default for ABS when you choose what filament type to load.

RE: ABS Printing with the MINI+

Not sure what William is on about, but I commonly print PC & PC-CF@ 275-280°C regularly in ambient temperatures from 40-60°C with zero heat creep issues. My workhorse filament is ASA though and the quality comes out better than my MK3S+.

RE: ABS Printing with the MINI+

Not sure what William is on about, but I commonly print PC & PC-CF@ 275-280°C regularly in ambient temperatures from 40-60°C with zero heat creep issues. My workhorse filament is ASA though and the quality comes out better than my MK3S+.

It was about the heat-creep problem many have with the mini and the stock hotend. If it works for you, I'm glad to hear that.

I also just pointed out other problems many users have (but are not related to ABS printing) so he knows it before he buys a Mini

RE: ABS Printing with the MINI+

Been printing abs non stop for weeks on the mini

I did upgrade the hotend to a slice copperhead though