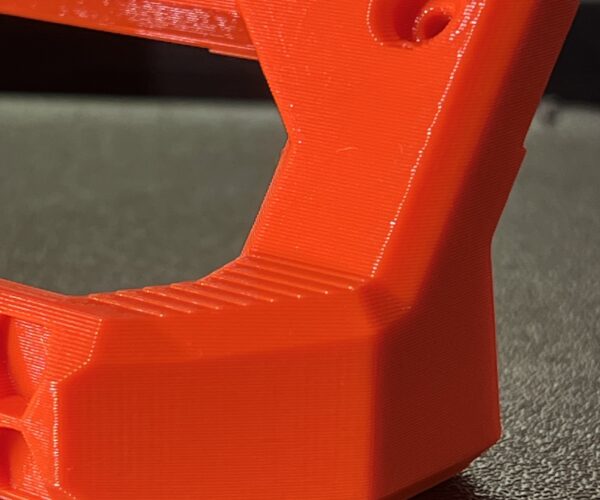

Over-extrusion part way through a PETG print

A few people are reporting a problem whereby PETG prints begin to produce very rough layers part way through a print. The print will begin smoothly, but some time into the print it's as though there's a lot of over-extrusion for a number of layers. There are a couple of reports on Reddit (e.g. here and here).

I tried printing the handle that's being discussed in the first of those links. I used PrusaSlicer 2.6.0-rc2, and the printer's on 5.0.0 Alpha2. The issue showed up around the 13mm point, but there's a bit of an issue below that as well, at around 5mm, where there's a ridge that shouldn't be there.

On my MK3S+, using the same slicer, there's no sign of either problem (over-extrusion or ridge), and the print looks good all the way up.

By trial and error, it looks like the problem appears after about 8.5m of filament have been printed. The model above uses 8 perimeters, but if I reduce that to 2 perimeters the problem shifts up from 13mm to 22mm. If I use the slicer to cut the bottom 11mm off the model, the problem then shows up at around 21mm (which would have been 32mm in the uncut model). In all three cases, the start point corresponds to about 8.5m of filament.

I've done prints in PLA that have used more filament than that and haven't seen this problem. It seems to be a PETG problem. I'm currently printing the above handle in PLA, just as a check.

The OP in the first of those Reddit threads says he's reported the problem to customer support, but I feel it would help to bring it to the attention of the developers directly. I realise that this forum isn't monitored by the Prusa developers, and that Github is the place to report issues like this, but it's not clear to me whether this is a firmware issue or a slicer issue (or both?), so I'm not sure which repository to report it under.

Anyone else seeing the same issue? If so, by cutting at the appropriate point in the slicer, can you confirm how much filament has been used when the problem starts?

RE:

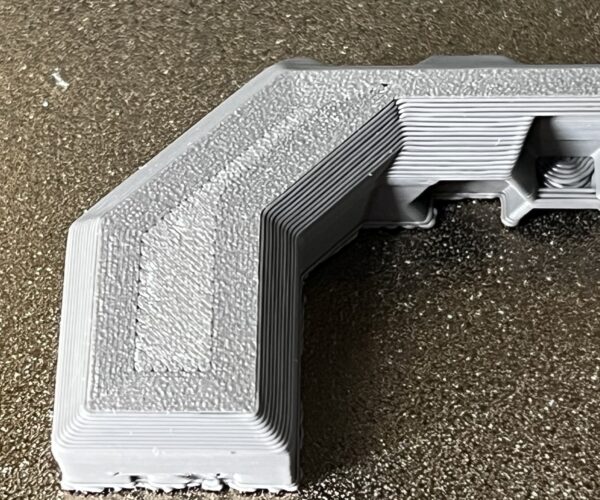

Uh oh - looks like I was wrong about it being restricted to PETG - this is with some 'Generic PLA'. Both problems are still present - over-extrusion and ridge.

This is odd - I haven't seen this with anything else that I've printed on my MK4. But looking back, I suspect the only prints I've done so far with more than 8.5m of PLA have been with the Input Shaper profile, and maybe all my other PETG prints so far have used less than 8.5m of filament. So I'm re-running this PLA print with IS.

RE: Over-extrusion part way through a PETG print

I should have checked again before posting - looks like this issue has already been reported under the buddy firmware repository: https://github.com/prusa3d/Prusa-Firmware-Buddy/issues/3121#issue-1784054807

RE: Over-extrusion part way through a PETG print

Thanks for this thread... I was just about to give the Alpha firmware a try, but I print about 80% in PETG and don't need this problem. Seems like a pretty high priority item, so hopefully we won't have to wait too long for resolution!

Please show us the underside of a failed print.

Cheerio,

RE: Over-extrusion part way through a PETG print

Thanks for this thread... I was just about to give the Alpha firmware a try, but I print about 80% in PETG and don't need this problem. Seems like a pretty high priority item, so hopefully we won't have to wait too long for resolution!

I wish I could change the title of the thread. It's not restricted to PETG - I had the same result when printing that model with PLA. What misled me was that I hadn't seen it in any of my earlier PLA prints, but I realised that they'd all been with the IS profile, and I've now confirmed that the IS profile doesn't exhibit this problem.

I agree, it seems like it should be a high priority fix, assuming they can reproduce it at Prusa. It means that a great many prints will be poor quality, unless the IS profile is used, which I believe is only aimed at PLA in this version of the firmware. But it's a thing to behold when the printer's going full tilt on an IS PLA print! I can't wait for it to become the default for all prints.

Please show us the underside of a failed print.

Cheerio,

It's definitely not an adhesion problem. In all cases I've had no lifting whatsoever, and the phenomenon occurs over the whole layer. The images posted by the author of the bug report show the problem repeating on and off over the full height of some rather tall, thin prints. It looks like fewer perimeters were used in those prints, since the effect is less pronounced, but I think that fits with it being an error in the extrusion width/volume perhaps - with fewer perimeters there's more space for the excess material, whereas with those 8-perimeter prints it can only squish out to the outside.

RE: Over-extrusion part way through a PETG print

So what's the difference between the IS and the non-IS profiles? My Mk4 is en route right now so I haven't looked at those profiles yet.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

From the user's point of view, the difference is that selecting the 'Original Prusa MK4 Input Shaper (Alpha)' Printer preset gives you only a single Print setting preset ("0.2mm Input Shaper"). I had read that it only works with PLA, but having just compared some print times in the slicer I don't think that's correct - it seems to give the same time saving with PETG too.

I don't have a great deal of experience with it yet, but I've been very pleased with the quality of some 0.2mm IS prints. This is a cylinder for a circular sock knitting machine. I figured it would be a good test for IS, due to all the direction changes, and the fairly uniform profile as the height (and therefore mass) increases. The complex shape certainly generated quite a bit of shaking in the printer's frame, but the finished print seems every bit as good as one that I printed on my MK3S+, and instead of taking ~17hrs it took only 6h45m.

RE: Over-extrusion part way through a PETG print

I just loaded the IS profile and compared it to the regular one. I don't see many differences apart from the obvious huge differences in speed and accelaration. Slight differences in retraction length, extrusion width for top solid infill, and infill/perimeter overlap, plus no wipe when retracting. None of which would explain your observations or why the IS profile would perform better. Confusing…

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

It's definitely not an adhesion problem.

Always worth checking. Offer the underside up against a straightedge and check for warping that might have lifted the build sheet. I don't expect to see it but it needs to be ruled out. There are a lot of perimeters so the warp stresses must be high.

I would also try cubic fill on larger parts to take some of the printing stress.

And as a double check, try slicing with 2.5 to highlight issues inherited from the original design.

Cheerio,

RE: Over-extrusion part way through a PETG print

Theres also the other differences such as the filaments pressure advance settings that the new firmware uses. I mean the printer start gcode has the M593 commands its using for the Input Shaping itself but the filament profiles have the M572 pressure advance settings. Considering that looks like quite a considerable amount of over extrusion when it does happen I am wondering if theres something messed up in the firmware's handling of that.

Given that it seems to happen after xx amount of extrusion (given the contents of this thread as I don't have a MK4) then its very likely firmware rather than anything the Slicer is putting into the gcode file beyond the fact that the profiles are including those sorts of values.

RE: Over-extrusion part way through a PETG print

Always worth checking. Offer the underside up against a straightedge and check for warping that might have lifted the build sheet. I don't expect to see it but it needs to be ruled out. There are a lot of perimeters so the warp stresses must be high.

I would also try cubic fill on larger parts to take some of the printing stress.

And as a double check, try slicing with 2.5 to highlight issues inherited from the original design.

Cheerio,

It's completely flat. The proof, for me, that it's not due to lifting, is that it happens across the whole piece at exactly the same layer, not just in one corner. It's entirely repeatable for a given gcode, but when sliced with a different number of perimeters it moves up or down the model, so I think that rules out any issues with the z-axis on my printer.

The same model, sliced with the same slicer and same settings, prints perfectly on my MK3S+, which I think rules out model artefacts.

RE: Over-extrusion part way through a PETG print

I'm printing a different model for a comparison. A simple cylindrical spindle, printed with 4 perimeters and 25% grid infill - settings that give enough strength for a 2kg spool of filament. It should be a smooth cylinder all the way up (apart from the lip at the bottom of the print), and it has been whenever I've printed it on my MK3S+ in the past. On the MK4, using PS 2.6.0 (non-IS preset) and FW 5.0.0-alpha2 it shows banding due to this variable extrusion issue.

The onset of the most serious over-extrusion happened at 83.6mm (I was watching the display, because I was expecting it). By cutting the model at this height and removing all the top layers I was able to determine that this layer corresponds to 7.9m of filament.

I'll only be able to measure the height of the other bands, shown with arrows, when the print is finished, but by scaling from the photo I think they're at about 30mm (3.15m of filament) and 75mm (3.8m of filament).

RE: Over-extrusion part way through a PETG print

Correction - the other bands occurred at 38mm and 15mm (the 30mm and 75mm were my raw measurements from the photo 🙄 ). These heights correspond to 1.87m and 3.95m of filament - interesting that the length of filament (almost) halves/doubles between the bands. The over-extrusion that started at 83.6mm never corrected itself - the print got as far as 168mm before detaching because I'd forgotten to add a brim.

RE: Over-extrusion part way through a PETG print

For confirmation I printed that spindle using the IS profile, and it's beautiful - perfectly smooth all the way up, with no sign of the variable extrusion issue.

A few off-topic but interesting observations:

Firstly, with the speed of the extruder movements, the whole printer was wobbling quite a lot. I have the printer in a Prusa enclosure, and I think a lot of the wobble is caused by the base of the enclosure flexing. As the spindle got longer, not only was the printer wobbling, but the top of the spindle seemed to be wobbling as well. It seems like a recipe for poor quality, but I'm astonished at the quality of the finished print. There's no visible difference between the bottom and the top. The wobble definitely justified the 15mm brim though.

Secondly, this is PETG, so I'd expect the finish to be quite shiny, like the smooth part in my previous picture. But in this print it's come out with a lot less shine - more a silk or even a matt finish - the photos look as though they're unfocussed, but there's almost no 'detail' for a camera, or the eye, to pick up on. You can just about make out the individual layers in the last photo (note that this is the "0.20mm Input Shaper" profile, but I changed the layer height to 0.3mm). I'm guessing this matt finish has something to do with the speed that the filament is being printed. Whatever the cause, I rather like it.

Finally, the screw thread at the top of the spindle is not as clean as I've seen on my MK3S+, and I was expecting it to be a poor/tight fit in the female threaded part. On the MK3S+ I deliberately use slow speeds because of the overhang on the threads - this seems to ensure a good fit. But in fact this IS print fits perfectly.

RE: Over-extrusion part way through a PETG print

Did you use vase mode? If not whats the seam like?

For confirmation I printed that spindle using the IS profile, and it's beautiful - perfectly smooth all the way up, with no sign of the variable extrusion issue.

A few off-topic but interesting observations:

Firstly, with the speed of the extruder movements, the whole printer was wobbling quite a lot. I have the printer in a Prusa enclosure, and I think a lot of the wobble is caused by the base of the enclosure flexing. As the spindle got longer, not only was the printer wobbling, but the top of the spindle seemed to be wobbling as well. It seems like a recipe for poor quality, but I'm astonished at the quality of the finished print. There's no visible difference between the bottom and the top. The wobble definitely justified the 15mm brim though.

Secondly, this is PETG, so I'd expect the finish to be quite shiny, like the smooth part in my previous picture. But in this print it's come out with a lot less shine - more a silk or even a matt finish - the photos look as though they're unfocussed, but there's almost no 'detail' for a camera, or the eye, to pick up on. You can just about make out the individual layers in the last photo (note that this is the "0.20mm Input Shaper" profile, but I changed the layer height to 0.3mm). I'm guessing this matt finish has something to do with the speed that the filament is being printed. Whatever the cause, I rather like it.

Finally, the screw thread at the top of the spindle is not as clean as I've seen on my MK3S+, and I was expecting it to be a poor/tight fit in the female threaded part. On the MK3S+ I deliberately use slow speeds because of the overhang on the threads - this seems to ensure a good fit. But in fact this IS print fits perfectly.

RE: Over-extrusion part way through a PETG print

Alpha3 is out, and while it doesn't specifically mention a fix for this problem, it does talk of fixes to layer shifts and layer skipping, with adjustments to Pressure Advance which "also fixes all remaining issues of PA during filament manipulations". I'm currently reprinting the gcode for the handle in my first couple of posts above, and so far so good - it's got past the first ridge (described as 5mm above, but actually at 6.8mm after measuring) with no sign of any variable extrusion.

Fingers crossed for the rest of the print....