clogged nozzle (Solution)

Hello everyone

I had the following problem with my factory assembled Prusa MK4: After some time while printing, the hotend always got clogged.

I was able to print some files and the hotend kept clogging up with larger ones. I stumbled upon the following video by accident, which had the same problem:

So now I want to post my solution here in case someone has the same problem and point it out to Prusa so that this error doesn't happen anymore.

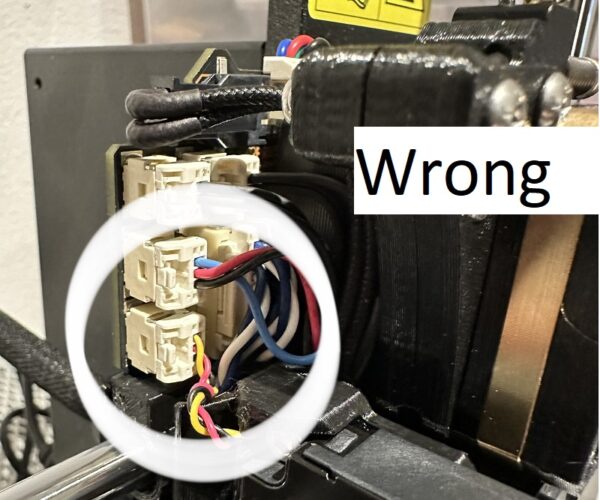

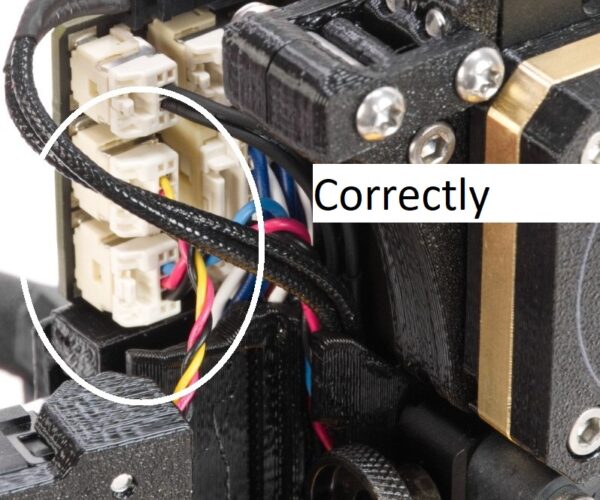

The two fans were incorrectly connected to the board and must be replaced.

This is easily done by removing the Loveboard cover and swapping the plugs.

I hope I can help some as well.

RE: clogged nozzle (Solution)

Strange not to idiot proof the sockets with a key variation or at least color coding the plugs? Some variation to make that more clear.

RE: clogged nozzle (Solution)

My MK4 clogged up after the 4th print... the wires for the fans were assembled backwards... sigh....

RE: clogged nozzle (Solution)

Since the Nextruder has an additional thermistor in the heatbreak, a selftest might detect swapped plugs. Apparently, the firmware still lacks such routine.

Detecting backwards assembled wires seems harder -- at least if you do not want false alarms and consider potentally modded printers as well. Or, maybe, it is not so hard if a selftest compares the thermal response for both fan rotation directions. That is, if the board allows to do so.

RE:

An easy mistake to make when you mind is given repetitive tasks.

--------------------

Chuck H

3D Printer Review Blog

RE: clogged nozzle (Solution)

Before I disassemble stuff, I try to make at least one photo showing which wire/cable/plug goes where. At least the wires on the fan plugs have different colors. As you have to remove the plugs when you change a nozzle on the MK4, a photo taken beforehand could be a valuable resource. 🙂

RE: clogged nozzle (Solution)

An easy mistake to make when you mind is given repetitive tasks.

Yea but it's not an assembly mistake. It's a design mistake.

RE: clogged nozzle (Solution)

sadly thats not it for me (the cables are like in the "correct" photo of the op)...

and it seems to happen only with fine layers (o.1mm) ... had 5 Misprints with 2 different filaments.

(yes, i did the nozzle cleaning process with the needle and made sure the filament purged fine (to me, still a noob with the whole printing stuff ^^)

Always a clogged nozzle and broken filament on top of the feeding tube (between nextruder gear and "feeding tube" of the nozzle). At least when i got to it, which was always some time after the incident.

switched to 0.2mm layer hight, will see if it helps ...

RE: clogged nozzle (Solution)

seems editing posts is time-constrained?

Update1: layer height 0.2mm printed fine.

will try the 0.1 with a temperature of 220°c instaed of the default 215 ... but not today. I will keep this updated, Ideas and comments are very welcome 🙂

RE:

I also got a clogged nozzle on my first print with PETG. I was able to unload the filament, but the extruder would not load new filament as it made rattling noises when trying to push it into the hotend. Turned out the filament got broken right underneath the top of the metal tube:

To get it out I set the extruder temp to 280° and tried to push the filament upwards with a cleaning needle, but without success. So I again took the hotend out and used a heatgun to finally push the remaining filament with a needle up and out of the metal tube. The needle now went all the way through the nozzle, but there was still too much molten filament stuck to get new filament loaded. So I tried to do multiple cold pulls with PLA (inside the extruder with the Idler Swivel opened and external with the heatgun), but that didn't work. Prusa support was very nice and even offered a replacement nozzle, but in the end I was able to clean the nozzle with the Noclogger tool and the extruder is working again.

I like the new hotend design without the PTFE tube, but cleaning the metal tube seems to be a really hard task. If that happens frequently, Prusa should add something like the Noclogger tool to the package.

PS: Cables were connected correctly on my factory assembled printer.

RE: clogged nozzle (Solution)

Does the no clogger pass by the extruder gear, or only with the nozzle out of the nextruder?

RE:

no, even if you disable the filament sensor, you won't get past the drive gear without the Noclogger touching and maybe damaging it

RE: clogged nozzle (Solution)

no, even if you disable the filament sensor, you won't get past the drive gear without the Noclogger touching and maybe damaging it

How did you go about using the NoClogger with the MK4 without it damaging the gear?

RE: clogged nozzle (Solution)

Will acetone dissolve the PLA?

RE:

no, even if you disable the filament sensor, you won't get past the drive gear without the Noclogger touching and maybe damaging it

How did you go about using the NoClogger with the MK4 without it damaging the gear?

taking the nozzle out and heating it with a heatgun