Any way to change the Z Offset?

My MK4 seems to be printing well, and the first layer is very consistent. Unfortunately, it's just a hair too close. Every print it's just a bit off. On my Mk3 machines, I'd just raise the offset by 0.02mm, and that would probably be perfect. Is there any way to change the Z-offset for the MK4? If not in the hardware, is there something I could add to the starting G-code to raise it up by 0.02mm each print?

RE: Any way to change the Z Offset?

Go to the release announcements for firmware 4.6.1 and look for "Changes to Live Adjust Z". Should still apply to version 4.6.2 and is at least one way to to what you want, not automatically for every print, but possible.

RE: Any way to change the Z Offset?

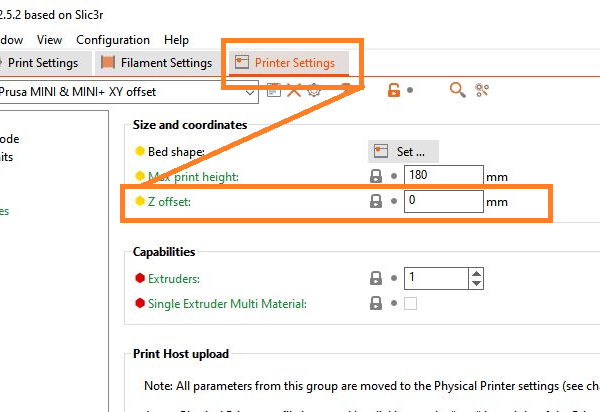

Yes you can specify that in prusa slicer.

Click on the printer settings tab and for the Z offset enter the value 0.02.

After this adjustment, save the settings.

After this, every time you print, the value in the gcode is adjusted.

RE: Any way to change the Z Offset?

Ooh, that's exactly what I needed, at least for now while I have only 1 MK4. Once I get more, we'll see if they all are consistent with each other, and the same value works for all of them. Hopefully they'll implement this into a firmware adjustment that you can dial in for each printer. Thanks!

Yes you can specify that in prusa slicer.

Click on the printer settings tab and for the Z offset enter the value 0.02.

After this adjustment, save the settings.

After this, every time you print, the value in the gcode is adjusted.

RE:

It would be a good idea to make that offset a part of hardware profiles, set on the printer, as it was on MK3 with different print beds. For textured sheet I always squish Z some more, to hide the first layer head streaks.

RE: Any way to change the Z Offset?

I now also got into this and found this setting via Support. I need +0.05 and now need to add it to each single print, since it cannot be stored permanently. According Support this "Z offset" in the slicer will not bring a difference, but I did not try it. I'm disappointed now, since if need to apply offset for each print, the whole Loadcell leveling feature does not make sense...

RE:

Hi, the loadcell aim is to avoid the necessity to set the z-offset . The correctness of the MBL significantly depends how clean is the nozzle tip during MBL and whether the loadcel sensitivity tolerance is within the required threshold. The z-offset is then done automatically. The first layer pattern can be different for the same material with different nozzle temperatures, which could be the solution for a good first layer.

RE: Any way to change the Z Offset?

Yes, the same for me. I added some extra squish of 0.02 for my first layer of PETG. And with slow printing I'm able to remove the traces of the printing completely. But I also have one mk4 and use only the satin sheet.

So I do it right now in the slicer, but it does not feel right. But if all MK4 behave the same (the chances are fair with the load cell), the slicer solution should be ok.

RE: Any way to change the Z Offset?

Prusa Support told that this z-offset setting does not matter on mk4. My delta is around 0.05. Cleaning the nozzle before printing is not easy on mk4, since the nozzle is not hot enough for this when its steady, and it start moving to the home position when it is hot

RE: Any way to change the Z Offset?

Oh wow, thanks Vladimir! So did I trick myself? I'll test the offset value again and write back.

I found out, that if I print directly after a filament change, that there is of course much more oozing. And then I also had the issues, that the z-probing left some filament dots all over the build plate. So there is a fair chance, that I just have an issue with a dirty nozzle and nothing else. I'll do some more tests (I stopped testing, as the results were reasonable and the results ready to sell).

Prusa Support told that this z-offset setting does not matter on mk4. My delta is around 0.05. Cleaning the nozzle before printing is not easy on mk4, since the nozzle is not hot enough for this when its steady, and it start moving to the home position when it is hot

RE: Any way to change the Z Offset?

Hi Vladimir, I sliced an object twice. One with an offset of -0.03 (left in screenshot) and one with an offset of 0.3 (right). The first G1 movement is changed by this offset - the left is G1 Z.017 and the right one is G1 Z.5. And the printed objects behaved as expected: With positive z offset there a gaps between the lines.

Interestingly, the purge line is not modified by this - it's in both cases Z0.2.

The the offset is working - so the question for me remains, of this will be the same for all mk4 or should it be a feature for an individual printer.

Prusa Support told that this z-offset setting does not matter on mk4. My delta is around 0.05. Cleaning the nozzle before printing is not easy on mk4, since the nozzle is not hot enough for this when its steady, and it start moving to the home position when it is hot

RE: Any way to change the Z Offset?

Sorry, another late update: You can do a z adjust at the printer if you keep the dial knob pressed during an active print.

RE: Any way to change the Z Offset?

Certainly... The only problem with this that this setting is reset on each new print. You need to keep setting it each time...

RE: Any way to change the Z Offset?

This doesn't really solve the problem, though. The issue is not that we can't adjust the Z offset at all, it's that we can't dial in each printer individually. I know that all of the prusas are supposed to behave the same, and within a certain tolerance, they do. But, they are not exact. My 6 MK3S+ machines are very close to each other, but one clearly runs hot, as the prints are more likely to come out shiny on that one, even printing the same file with the same roll of filament as another machine. Having multiple machines means that you need some way of dialing in each one to account for the individual quirks. As of right now, if you have 3 MK4 machines, and one of them levels itself slightly higher than the others, there is no way to account for that in the firmware. Each printer should be able to have it's individual offset adjusted, so if you know your machine needs an extra 0.02 of squish, you can do that.

Sorry, another late update: You can do a z adjust at the printer if you keep the dial knob pressed during an active print.

RE: Any way to change the Z Offset?

I fully agree with this. I've had the MK4 for 3 days now and was extremely disappointed when I couldn't successfully complete a single print at first. It was only after learning about the solution presented here that I was able to do so. I had to set the Z offset to -0.25(!!) in order to achieve a clean and adhesive first layer.

However, this cannot be Prusa's final solution. Reasons have already been mentioned. I would like to add that this method does not allow for the sharing of G-codes. The G-code that works on my MK4 could potentially cause significant damage to the print sheet on any other MK4.

This doesn't really solve the problem, though. The issue is not that we can't adjust the Z offset at all, it's that we can't dial in each printer individually. I know that all of the prusas are supposed to behave the same, and within a certain tolerance, they do. But, they are not exact. My 6 MK3S+ machines are very close to each other, but one clearly runs hot, as the prints are more likely to come out shiny on that one, even printing the same file with the same roll of filament as another machine. Having multiple machines means that you need some way of dialing in each one to account for the individual quirks. As of right now, if you have 3 MK4 machines, and one of them levels itself slightly higher than the others, there is no way to account for that in the firmware. Each printer should be able to have it's individual offset adjusted, so if you know your machine needs an extra 0.02 of squish, you can do that.

Sorry, another late update: You can do a z adjust at the printer if you keep the dial knob pressed during an active print.

RE: Any way to change the Z Offset?

I'm now on 20 days of printing on the counter and see that the problem has settled a bit, but not gone. The first layer is still not so perfect as I can tune it on mk3s+. I also learned for myself that a clean nozzle matters lot even though there is a "nozzle cleaning" step. I started (or resumed what I do on mk3s+ anyways) to clean the nozzle from the leftovers each time with a cotton swab. I recently installed the 5.0.0 with Input Shaper... I do not have a full test yet, but it looks like z-layer calibration now works a bit better

RE: Any way to change the Z Offset?

Alright, I was also quite disappointed, that the live z offset is reset to 0 for each print. So it's ok for testing, but not usable adjustment of individual printers.

So I guess the simples solution would by to set the live z offset permantly - so like the mk3. Then the issue solved. It's a pity, that this kind of adjustment is needed for the load cell system, but the other thing then would be the adjust the threshold for the probing. And then the z offset is probably easier to handle.

RE: Any way to change the Z Offset?

I'm not sure, if I did it right, but I created this as an enhancement at GitHub.

RE:

My observation after a few more weeks: I had ordered a textured shield along with the printer because I had the best experiences with it on the Prusa Mini.

I immediately set aside the smooth shield. After the problem described here, I used the smooth shield, and it works perfectly. However, the significant drawback of the smooth shield is that PETG adheres extremely. I hope for a solution to be able to use the textured shield again.

RE: Any way to change the Z Offset?

I've been using my MK4s for a few months now. After going through a whole (and seemingly unnecessary) load cell swap, I had the same first layer issues. Ended up setting Z height offset in PrusaSlicer for prints where the first layer visible quality is important and it's been working like a champ ever since. MK4s is a phenomenal machine!

However, I don't plan on buying any more MK4s to replace my MK3s. Instead I will likely replace them with Vorons as I already have a few of those. The reason? I just have too many models to bother with having to potentially slice all of them for each specific Mk4s I have just to set the Z offset. That would easily be multiple hundreds if not into the thousands of files.

I've been trying to get Prusa to update us on ( https://github.com/prusa3d/Prusa-Firmware-Buddy/issues/3306) noting that the assignee hasn't committed anything since February.

Otherwise, the only option I see fit (other than buying another brand printer which is likely what I'll be doing, unfortunately) is forking the firmware and adjusting the z-height values there and using custom firmware on each printer. Meaning I'd have to manage multiple forks.

I'm just baffled why Prusa is being so stubborn here, to an incredible fault relative to the fairly stiff competition. I don't expect z-height to be a thing for the novice to adjust. But for those of us with print farms or where first layer quality is paramount, it's *really really* important. They're turning me from a promoter to a detractor over this one feature and I don't understand why they're clinging to an idea that is increasing warranty part replacements and decreasing sales. At least my own sales. I'd buy another MK4s literally today save for this one feature.

I really don't like having to be obnoxious and making stinks I love what Prusa is does and have since I bought my first printer in 2019 (which I still have and will probably keep forever being my first). But I can't invest in printers that end up costing me more time and the human cost of having to slice models per printer is just too high.