Load Cell sensor - can somebody explain this to me?

I've haven't been able to figure this one out yet on my own and am hoping for some help. From what little I think I understand the nozzle is actually being lowered onto the bed until they both make contact and that's the leveling process?

If that were the case, is a ruby nozzle going to be damaged / become a problem with load cell bed leveling?

RE: Load Cell sensor - can somebody explain this to me?

It's like an upside down scale. The sensor detects resistance and uses that measurement to detect a surface.

Similar to what the Ultimaker has used for many, many years or a variety of lesser printers use nowadays. Very accurate and simple way to determine a surface by feeling for resistance.

RE: Load Cell sensor - can somebody explain this to me?

Does someone know the load that is applied to the surface? I would like to print on a soft surface.

RE: Load Cell sensor - can somebody explain this to me?

Based on information about the load cell function given here and possibly here, printing on a soft surface may prove problematic. When the load cell is "leveling the bed" it is also checking to see that the nozzle tip is free of plastic. If it detects that the touch feels squishy then it moves the nozzle sideways to wipe off the nozzle. I assume that a soft build surface would confuse the software and prevent it from establishing the correct build surface location. Certainly would be easy enough to test. If you can give me an an idea of what you have in mind with a proposed test object I can give it a try. Note: At this point I haven't printed anything with my MK4 due to other important (think taxes) projects.

RE: Load Cell sensor - can somebody explain this to me?

It's like an upside down scale. The sensor detects resistance and uses that measurement to detect a surface.

Similar to what the Ultimaker has used for many, many years or a variety of lesser printers use nowadays. Very accurate and simple way to determine a surface by feeling for resistance.

And the nozzle being used to determine that, I suppose.

I guess it does so very, very gentle but there's a chance it might damage my ruby nozzle, no?

RE: Load Cell sensor - can somebody explain this to me?

During the initial setup tests the routine askes you to touch the nozzle to test the load cell. It responded with the lightest of touches. I thing the nozzle is under greater pressure when it is extruding plastic onto the build surface.

RE:

Saw a twitter post where someone had printed a pretty great looking 1 layer surface onto a piece of corrugated cardboard secured to their print bed. It followed the uneven top surface perfectly. Last time I checked cardboard its the hardest thing around.

Found this reddit of it too https://www.reddit.com/r/prusa3d/comments/12fa028/perfect_first_layers_every_time_on_any_surface/

RE: Load Cell sensor - can somebody explain this to me?

During the initial setup tests the routine askes you to touch the nozzle to test the load cell. It responded with the lightest of touches. I thing the nozzle is under greater pressure when it is extruding plastic onto the build surface.

Cheers, I just read about people going too low with their ruby nozzles and breaking it, so load cell leveling sounded like a bad idea with a ruby nozzle at least. If the load cell sensor is extremely sensitive though, then I guess that's simply not an issue no matter the nozzle.

RE: Load Cell sensor - can somebody explain this to me?

I asked the question on the Prusa chat (do not recall the person), but they said they had tested this and it should not be a problem. I have a Ruby nozzle that I have been waiting to install for quite some time now, and once I can get a whole new hotend for use with the Nextruder, I will be installing it and trying it out.

RE: Load Cell sensor - can somebody explain this to me?

I would worry less about the nozzles than the printing plate.

Pressing a small hot metal tip on a smooth plate surely won't do much. I don't know if probing is done at printing temperature but even if it's done at lower temperatures, I expect that the plate will soon be full of marks. Textured plates are more resistant but still..

RE: Load Cell sensor - can somebody explain this to me?

Why?

I have been doing the pre-heated hotend to 160 when it does mesh bed leveling for at least 3 years, and no marks on any sheets at all. On top of that, the MK3 does all its mesh bed leveling in the same spot, this will probe only where it will be printing. Besides, print sheets are consumables anyway, so they will need to be replaced eventually.

RE:

Why?

I have been doing the pre-heated hotend to 160 when it does mesh bed leveling for at least 3 years, and no marks on any sheets at all. On top of that, the MK3 does all its mesh bed leveling in the same spot, this will probe only where it will be printing. Besides, print sheets are consumables anyway, so they will need to be replaced eventually.

The MK3 doesn't touch the bed during mesh bed leveling, so it would not leave marks on any sheets after 3 or 300 years (barring user error or firmware glitch). The MK4 does touch the bed during mesh bed leveling.

RE: Load Cell sensor - can somebody explain this to me?

I realized this after I had posted and left for the day.

RE: Load Cell sensor - can somebody explain this to me?

The nozzle is significantly cooler (@170 C) than the hot plastic that's normally deposited on the sheet. Why should a nozzle barely touching the bed put a lot of visible marks on it any more than releasing plastic ~40+ degrees C hotter onto it, I'm not sure. The nozzle may be not be touching with much force at all. But after doing my first couple of prints I will examine the sheet closely...

RE:

There's a mod for Voron printers which also probes the bed with the hot nozzle for automatically setting the Z offset of the first layer,

Quoting from the FAQS page of Voron's Githuh for this mod ( known as'TAP' ) :

"Will Tap hurt my print surface? : No, probing temp is restricted to 150C. The team recommends spray coated spring steel. Users of smooth PEI may find minor burnish marks if continously probing the same spot."

So I understand that even if Prusa uses higher probe temperatures (170C?) smooth plates won't be destroyed in a few days, but users should expect some kind of marking after a while. How visible the marks will be depends mostly on the plate. Spray coated/textured plates are much stronger in this respect than glued PEI sheets. Another question is if the burning marks will be just a matter of aesthetics or if it affects the adhesion of the filament to the bed.

RE: Load Cell sensor - can somebody explain this to me?

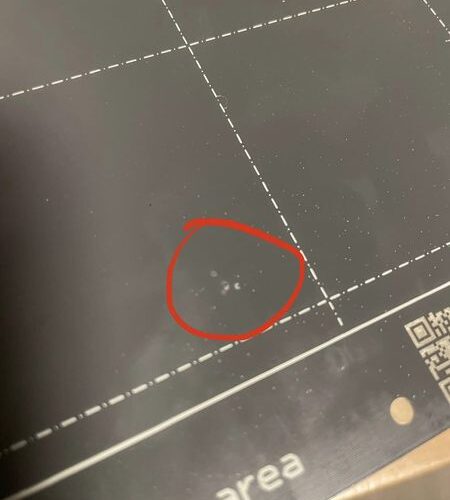

As of the MK4 release firmware (4.5.4) the Load cell tapping presses a bit hard into the build plate. If it is repeatedly pressing into the same point (eating through the PEI layer) it will eventually start ramming against the steel.

I'd assume that because ruby is stronger than steel, it wouldn't be damaged though but it's worth considering.

RE: Load Cell sensor - can somebody explain this to me?

Thats concerning - I wouldn't expect it to leave marks on the sheet like that, I thought it was much more sensitive.....

RE: Load Cell sensor - can somebody explain this to me?

In fact, it is very sensitive for MBL around the printing area. But here in the case of Z-homing, not quite, because the Z axis movement would take an insanely long time if it was same sensitive as for MBL. We'll see what they come up with with the next FW upgrade.

RE: Load Cell sensor - can somebody explain this to me?

Have completed 25 print sessions on my MK4. I am not experiencing any issue with the PEI sheet being damaged by the nozzle pressing on the sheet. Time will tell.

RE: Load Cell sensor - can somebody explain this to me?

I have at least one dimple on my smooth sheet as well. Doesn't seem to happen from the probing process, but possibly from homing or the nozzle cleaning routine.