Vibration artefacts on Y-Axis

I see some vibration artefacts on the Y-axis. The print bed is smooth and without any friction. It moves the same as the x-Axis. You can hear the stepper motor - but nothing else.

Unfortunatelly I do see some artefacts just on the Y-axis. See the picture (lower part is Y-Axis, the upper part with the same print setting the X-Axis).

The effect is visible on the regular MK4 Firmware as well as on the MK4IS firmware, whereas the effect increases with printing speed. The raster itself (distance between the waves) is independent on print speed. Wavelength is the same in low and high speed mode.

I did a lot of fineadjustments on the printbed but without success.

RE:

If speed makes no difference to the spacing, that means it is 100% position based and you should focus your attention to the Y-axis stepper/belt assembly. There may be something going on where it encounters extra friction at a specific point in rotation.

Items to check:

- Stepper motor shaft rotation

- Stepper motor pulley and grub screws (make sure one of the screws is aligned with the flat side of the drive shaft, and both are tight)

- Idler pulley

Considering the spacing and regularity of the artefacts, it's highly unlikely that there would be any issue with the linear bearings sticking on the rails, or the belt itself.

RE: Vibration artefacts on Y-Axis

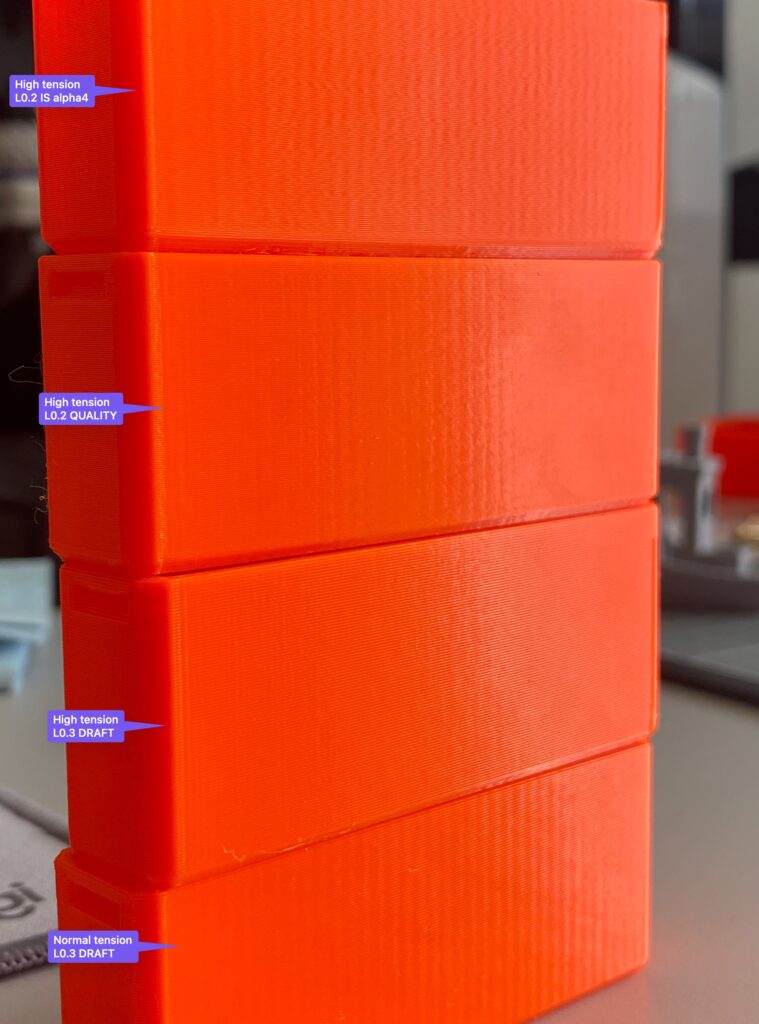

I got it improved by increasing the tension of the y-belt - much higher than expected and measured by the App (resonanz frequency). I will see how this will effect the livetime of the belt

RE:

From buttom to top: regular tension; high tension; very high tension (whatever that means).

The pitch is the same as the belt - therefore the stepper is out of the problem (much higher pitch).

RE: Vibration artefacts on Y-Axis

Have you printed a ringing tower test?

Input Shaping | Marlin Firmware (marlinfw.org)

RE: Vibration artefacts on Y-Axis

I'm having the same issue. Only on the Y axis, even spacing between artefacts, speed increases the effect but the spacing remains constant.

RE: Vibration artefacts on Y-Axis

For me, the pattern corresponds to the ribs of the belt.

Also only on the Y axis. Input Shaper has no effect on it.

RE: Vibration artefacts on Y-Axis

There are two things you can do: Increase belt tension. At least you should try very high tension above the recomended setting. And you can slow down the speed of the outer perimeter.

RE: Vibration artefacts on Y-Axis

Sure, but I don't really want either. There must be a reason why it occurs and always only Y.

A quick Google search resulted in a belt change or exchange of the smooth idler pulley for a normal one.

I will remove the Y belt again and check everything. Otherwise try the support.

RE:

In this thread I have Gcode for measuring the resonance.

Perhaps we can collect information about measuring input shaping in a thread.

RE: Vibration artefacts on Y-Axis

This is interesting because the idler pulley on the MK3S+ is also smooth, yet I don't have these artefacts on my MK3S+. So can it really be the cause of the issue? And the belt seems to be the same as well.

And yeah, over tightening the belt might hide the issue, but it will stretch the belt way faster + it can stretch it unevenly, requiring much quicker replacement. And then the issue will come back with the new belt. It's not a solution to the root cause, whatever that might be.

Sure, but I don't really want either. There must be a reason why it occurs and always only Y.

A quick Google search resulted in a belt change or exchange of the smooth idler pulley for a normal one.

I will remove the Y belt again and check everything. Otherwise try the support.

RE: Vibration artefacts on Y-Axis

On the MK3 I do not have the high speed of the MK4 and I only see the artefacts with the high speed of the InputShaper (that was the point I was getting aware of the issue).

If it will endup in a shorter lifetime of the belt I can live with - it will be a consumable lower than the Filement- and energycost.

If Prusa will come up with another solution than it's fine. The support couldn't help me and guided me to retighten all screws also on the x-axis (which did not change anything)

RE:

Those artefacts happen to me on the stable firmware, stock quality preset speeds. The artefacts appear on the external perimeter, which uses the same speed as MK3S+. My MK3 doesn't have these artefacts, yet the MK4 does.

Did tightening the belt get rid of the issue completely? Is the Y axis banging repeatedly for homing when the belt is too tight? Any other artefacts caused by a tight belt?

The fact support didn't know what to do is worrying. I don't want to overtighten the belt as a bandaid... :/

On the MK3 I do not have the high speed of the MK4 and I only see the artefacts with the high speed of the InputShaper (that was the point I was getting aware of the issue).

If it will endup in a shorter lifetime of the belt I can live with - it will be a consumable lower than the Filement- and energycost.If Prusa will come up with another solution than it's fine. The support couldn't help me and guided me to retighten all screws also on the x-axis (which did not change anything)

RE: Vibration artefacts on Y-Axis

The problem is not just the belt, but the stepper bearings and the additional friction in the stepper. It can also get too hot.

@Volker did you use the app to measure? What frequency do you have X/Y? Where are you measuring? There is a difference depending on whether it is at the top or bottom of the belt.

RE: Vibration artefacts on Y-Axis

After a hard day of testing ... I guess the poor fella just isn't made for input shaping? My second floor came out okay but im sure the bearing and the flip flopped values I had for dampening didn't help much either. Good thing I have some bearings on hand. For the record I used LUCAS on the x and super lube on the y. Super wins, I guess. I think it's breaking down a little more.

RE:

Important NOTE: That poor Sammy Davis Junior bearing didn't exist. It wasn't good news at first balls deep into a teardown. After I got all the bearing covers off and they themselves free -sliding to test them-, I discovered that I was producing the sound still. Hard to isolate inside of an enclosure. As I tried to zero-in, I got a brief wave of panic because it seemed it was coming from the X-axis motor area. And since I have been having talks with Support about testing alpha and they tell me they won't cover anything should x happen, and it's a kit so the fault is automatically yours ... (eyeroll) ... but then ... realization after ear to the motor and producing the sound it didn't sound as expected ... something else but what? Why does it also seem like it's coming from the pulley? Nope! So, lets remove the motor and hand turn just to be sure. Eureka! I produced the same exact sound from the first screw I touched. The middle or 2 O'clock screw.

So, this fits well. As I had retuned the belt with the app. Then after a lot of input shaping, 170ms stock speed on most stuff, started getting the noise. Originally I believe I applied .4 nm to those screws, but during my adjustments it got changed to .2 nm for the y-belt. (I do this for plastic to plastic mostly or .3) metal to metal like the frame and such I use .5 plastic to metal .4 Anyhoo, I tightened it back to .4nm and I haven't reproduced the sound yet.

So yes, it's a kit and the fault is mine. =)

RE: Vibration artefacts on Y-Axis

@paul-harbin, I'm sorry it wasn't clear what was the fix?

RE: Vibration artefacts on Y-Axis

After checking everything. All screws tightened on the Y axis. The Bed moves softly.

Both Belt Tighten with the Prusa Tool shortly before maximum.

Is it actually better now. That's how I am satisfied.

I have now used Damper that are for speakers under the stone slab. I don't know if it makes a difference.

RE: Vibration artefacts on Y-Axis

During the process of using "the app" to tune the belt (didn't use it during assembly) I left a screw not quite turned on the X axis. The clicking is a combination of a loose screw and the belt. I assumed it was a bearing when I heard it while still in the enclosure. During teardown to check which bearing was clicking, I figured out the sound was actually this. I had to make a TPU tray print to put silica in my filament dryer. Then I decided to run the roof print with only guess work. Anyhow, I retuned my slicer settings after I started my roof not before according to the measurements from the test. Trimming down the perimeters from 170 and such as well. No accelerations over 3000 and some only 1500 I hope we get more implementations of the full IS from Marlin soon to try some of the different goodies. I'll post some results tomorrow.