Help with First Layer Configuration

Hello,

I know this is a highly discussed topic, with tons of information already. I tried to follow everything I could find in that topic and I still think I'm not getting the right configuration.

So this time I printed a simple part and started noticing patterns that could be either Z layer too high or too low... I would like some help to figure out what it really is.

I upgraded my MK3S+ to a MK3.5S, my Z First Layer calibration is at -1.400

When I print this model: https://www.printables.com/model/521759-prusa-spatula-printables-sample-model

Please look at the pictures and please let me know your suggestions.

PS: When I run the First Layer calibration, everything seems fine, but when I print this part... that happens (pictures)

Thank you,

Best Answer by Neophyl:

First I'd stop trying to dial your first layer in with as benchy. A waste of filament but also time. As all we are interested in is the first layer then an object that is a single layer high is all that is needed. Something like our very own foxruns strip is more than enough https://www.printables.com/model/105404-calibration-strip-for-simple-live-zfirst-layer-cal

You really need to examine the top and with a single layer object you adjust as its printing requires less passes and far less time. When you peel it up after its cooled down, you bend the thin sheet produced and if the lines stay solidly together they are squished enough, if they break apart you need lower. You can also see any drag marks/waves in the top surface that indicate you have gone too low.

Once you have a first layer you are happy with you are likely to have a small lip around items you print. This is known as an 'elephants foot'. The slicer has a setting to counteract this where perimeters on the first layer are shrunk. Once the live z is set you can then tune the elephants foot setting to remove the lip.

Only once that stage is done do you then adjust for a brim. That has a setting called 'brim separation gap'. That is used to move the brim outwards slightly, weakening its attachment. So you want that attached so it can do its job but not too attached.

Your point about having to redo this every time you swap sheets, then no. The Mk3 firmware has 'slots' where you can store the live z values of several different sheets. So you do this for each sheet you have and then store the values in the different slots. You then can select the appropriate slot when changing the sheet over and your saved value is recalled. So basically once per sheet.

Also with the right single layer model and a bit of practice its becomes quick and easy to do this anyway if you do for some reason need to.

You are correct that with the mk4 you shouldn't need to, but there have been some reports that the first layers are not always as good, due to a variety of factors. I've even seen posts on here where some users wished they hadn't updated as the first layer was more reliable on the Mk3 (once its set properly)

RE: Help with First Layer Configuration

Not low enough, nowhere near enough squish on the first layer. Adjust your live z a lot lower.

RE: Help with First Layer Configuration

I'm new here so, help me understand, to lower more I have to go from -1.390 to -1.490? something like that not -1.390 to -1.290

Correct?

Not low enough, nowhere near enough squish on the first layer. Adjust your live z a lot lower.

RE: Help with First Layer Configuration

Correct. -1.490 is lower, ie closer to the build plater than -1.390. The PINDA probe range is approx 2mm which is why the Live Z setting goes down to -2.000. If you find yourself getting a bit close to the maximum in your adjustment of a perfect first layer then you will have to reposition the pinda slightly and redo the first layer calibration again after resetting Live zero back to zero. Hopefully though you will have enough adjustment range.

Basically you are aiming for something like this

Forgive the surface texture, that was printed on a 5+ year old smooth sheet that's seen a lot of use. Do note though how the extrusions of the first layer are all squished together and its an unbroken surface. Its just picked up every little imperfection and ding that surface has on it 🙂

RE: Help with First Layer Configuration

Got it.

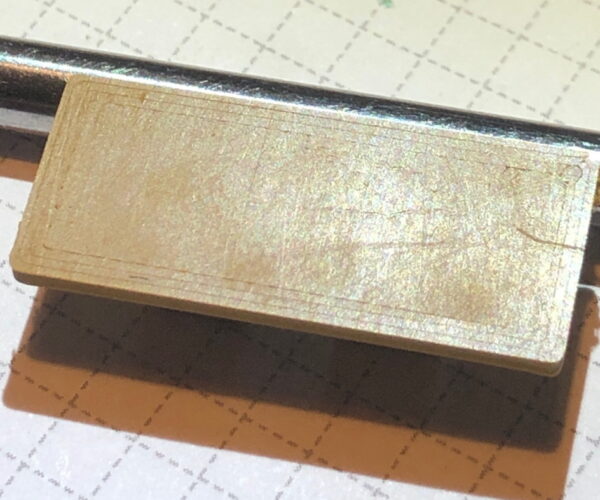

So this is -1.495

Bare with me, should I go lower?

Correct. -1.490 is lower, ie closer to the build plater than -1.390. The PINDA probe range is approx 2mm which is why the Live Z setting goes down to -2.000. If you find yourself getting a bit close to the maximum in your adjustment of a perfect first layer then you will have to reposition the pinda slightly and redo the first layer calibration again after resetting Live zero back to zero. Hopefully though you will have enough adjustment range.

Basically you are aiming for something like this

Forgive the surface texture, that was printed on a 5+ year old smooth sheet that's seen a lot of use. Do note though how the extrusions of the first layer are all squished together and its an unbroken surface. Its just picked up every little imperfection and ding that surface has on it 🙂

Lower.

You are aiming to start your print with a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

Cheerio,

RE: Help with First Layer Configuration

Quick question, if I go too low, now on -1.525, wouldn't I damage the PEI smooth sheet? I have seen some pictures of people with their steel sheet with a "ghost" of their prints "tattooed" in their sheet.

Thank you,

RE: Help with First Layer Configuration

No you wont unless you go 'too' far and bury the nozzle into the sheet. That benchy still has very clear separation between the extrusions. Looking at that I'd say you are going to end up very close the the -2.000 limit to get a good first layer. Thats what I was afraid of, you might end up adjusting and doing the whole first layer calibration again.

RE: Help with First Layer Configuration

Id say that was low enough 🙂 Nice squish there.

I'd also do a single layer print (just a simple square) to make sure that there no 'waves' on the top surface as that would indicate a fraction too low.

RE:

Nice! So I went -1.645, maybe too much? check out below: (it was way harder to take out the Brim, you can see some pieces are still attached to the bottom of the benchy)

This is a MK3.5S. If I upgrade to a MK3.9S with the auto-level Z layer feature, that means I don´t have to do this every time I switch the steel sheet, correct? I searched for this upgrade and it is not available... I hope Prusa make this available. (either MK3.5S to MK3.9S or MK3.5S to MK4S). The difference from the MK3S+ to the MK3.5S in terms of performance, precision and adjustment was incredible.

I envision switching between PLA and PETG, that means I will be switching between Smooth Sheet and the Texture sheet So that said, with the newer printers with the newer sensors this would be a thing of the past, right?

RE: Help with First Layer Configuration

First I'd stop trying to dial your first layer in with as benchy. A waste of filament but also time. As all we are interested in is the first layer then an object that is a single layer high is all that is needed. Something like our very own foxruns strip is more than enough https://www.printables.com/model/105404-calibration-strip-for-simple-live-zfirst-layer-cal

You really need to examine the top and with a single layer object you adjust as its printing requires less passes and far less time. When you peel it up after its cooled down, you bend the thin sheet produced and if the lines stay solidly together they are squished enough, if they break apart you need lower. You can also see any drag marks/waves in the top surface that indicate you have gone too low.

Once you have a first layer you are happy with you are likely to have a small lip around items you print. This is known as an 'elephants foot'. The slicer has a setting to counteract this where perimeters on the first layer are shrunk. Once the live z is set you can then tune the elephants foot setting to remove the lip.

Only once that stage is done do you then adjust for a brim. That has a setting called 'brim separation gap'. That is used to move the brim outwards slightly, weakening its attachment. So you want that attached so it can do its job but not too attached.

Your point about having to redo this every time you swap sheets, then no. The Mk3 firmware has 'slots' where you can store the live z values of several different sheets. So you do this for each sheet you have and then store the values in the different slots. You then can select the appropriate slot when changing the sheet over and your saved value is recalled. So basically once per sheet.

Also with the right single layer model and a bit of practice its becomes quick and easy to do this anyway if you do for some reason need to.

You are correct that with the mk4 you shouldn't need to, but there have been some reports that the first layers are not always as good, due to a variety of factors. I've even seen posts on here where some users wished they hadn't updated as the first layer was more reliable on the Mk3 (once its set properly)

RE: Help with First Layer Configuration

Thank you for the first layer only model ! much quicker now to adjust the first layer. You are right, you have to adjust at least once the first layer for each bed sheet, even if you have two of the same sheets (like for example 2 PEI smooth sheets), each one will need to be calibrated separately. Once they are stored, great! good point.

On the MK4S, so the first layer is not 100% fool proof? that then scares me, because when something is automated, you just expect it to work. But I guess even people using that Bambu X1C with all those sensors, and LidAR stuff also complain about sometimes the first layer not being perfect. Maybe the Core One will address that?

What do you think about the MMU3 and a MK3.5S together? People, in this forum, are complaining about the filament sensor not being reliable and some issues with different filaments and the first layer. Do you have any experience with MMU3? or multi-color printing ? I don´t plan to print anything crazy, but at least 3-4 color models (with white, orange, black and gray. like this model: https://www.printables.com/model/866524-lid-for-prusa-mk35-rugged-tool-box#preview.file.IjuCa

RE: Help with First Layer Configuration

About these two topics:

Once you have a first layer you are happy with you are likely to have a small lip around items you print. This is known as an 'elephants foot'. The slicer has a setting to counteract this where perimeters on the first layer are shrunk. Once the live z is set you can then tune the elephants foot setting to remove the lip.

Only once that stage is done do you then adjust for a brim. That has a setting called 'brim separation gap'. That is used to move the brim outwards slightly, weakening its attachment. So you want that attached so it can do its job but not too attached.

Could you please guide me to the right place to customize it?

Thank you

First I'd stop trying to dial your first layer in with as benchy. A waste of filament but also time. As all we are interested in is the first layer then an object that is a single layer high is all that is needed. Something like our very own foxruns strip is more than enough https://www.printables.com/model/105404-calibration-strip-for-simple-live-zfirst-layer-cal

You really need to examine the top and with a single layer object you adjust as its printing requires less passes and far less time. When you peel it up after its cooled down, you bend the thin sheet produced and if the lines stay solidly together they are squished enough, if they break apart you need lower. You can also see any drag marks/waves in the top surface that indicate you have gone too low.

Once you have a first layer you are happy with you are likely to have a small lip around items you print. This is known as an 'elephants foot'. The slicer has a setting to counteract this where perimeters on the first layer are shrunk. Once the live z is set you can then tune the elephants foot setting to remove the lip.

Only once that stage is done do you then adjust for a brim. That has a setting called 'brim separation gap'. That is used to move the brim outwards slightly, weakening its attachment. So you want that attached so it can do its job but not too attached.

Your point about having to redo this every time you swap sheets, then no. The Mk3 firmware has 'slots' where you can store the live z values of several different sheets. So you do this for each sheet you have and then store the values in the different slots. You then can select the appropriate slot when changing the sheet over and your saved value is recalled. So basically once per sheet.

Also with the right single layer model and a bit of practice its becomes quick and easy to do this anyway if you do for some reason need to.

You are correct that with the mk4 you shouldn't need to, but there have been some reports that the first layers are not always as good, due to a variety of factors. I've even seen posts on here where some users wished they hadn't updated as the first layer was more reliable on the Mk3 (once its set properly)

RE: Help with First Layer Configuration

Cant really comment about the MMU as I don't own one. I try to limit my posts to stuff I do know about 🙂 I very rarely need multicolour prints. I usually just design stuff that can be printed on its own and then assembled if It needs different colours. The occasional sign or badge that has raised letters or logos etc, but those can be done by filament changes at different layers rather than proper colour changes within a layer. There are enough people on here that do have them though. I'm sure if you start a specific post in the MMU forum with a suitable title they will respond.

Elephants Foot compensation is located under Print Settings>Advanced>Slicing>Elephants Foot compensation. Its a yellow setting so you need to be in Advanced or expert mode to see it listed. Printing a simple rectangle that's 1mm or more high should be enough is enough to see that and adjust it so its not a problem. Basically anything with vertical sides.

The Brim Separation gap is also a yellow setting. Located in Print Settings>Skirt and Brim>Brim. Just below Brim width.

The search bar is amazingly useful for finding a setting if you don't know where it is. It took many years for the search function to be implemented and its one of those often overlooked things that isn't flashy but oh so handy. Works surprisingly well.

RE: Help with First Layer Configuration

Thank you for all the help !

I posted the MMU3 questions here if you want to follow as well: https://forum.prusa3d.com/forum/original-prusa-i3-mmu3-general-discussion-announcements-and-releases/mmu3-mk3-5s-a-great-reliable-experience-or-mk4s-takes-the-throne/

RE: Help with First Layer Configuration

I'm new here so, help me understand, to lower more I have to go from -1.390 to -1.490? something like that not -1.390 to -1.290

Correct?Not low enough, nowhere near enough squish on the first layer. Adjust your live z a lot lower.

Correct! To get more squish, lower from -1.390 to -1.490, not -1.290. That’ll improve your first layer adhesion.

RE: Help with First Layer Configuration

I recently found a great model for use in 1st layer Live-Z calibration. I know there are several out there, but I like this one:

https://www.printables.com/model/163547-first-layer-calibration

The only thing is that you must go into the slicer and set the INFIL ANGLE to 90 degrees before slicing, so it does not fill the outline diagonally. I change my Live Z value every half-block.

RE: Help with First Layer Configuration

I ended up cheating. I sold my MK3.5S and bought a MK4S - no more headaches with 1st layer