Voron ABS parts with PETG as alternative

Those Voron printed parts are sold as ABS, can I opt PETG for ABS parts? At least for the Voron build. I did some search, these materials are both know for their strength and print at similar temperature. Is there a specific reason they have to use ABS?

RE: Voron ABS parts with PETG as alternative

Damn, the aid algorism already answered me https://all3dp.com/2/petg-vs-abs-3d-printing-filaments-compared/

RE: Voron ABS parts with PETG as alternative

The primary reason is the glass transition temperature of ABS is typically higher than PETG. Because of the enclosure, the long term temperatures will be higher within the voron, especially near the hotend. The worry is that the plastic structural materials will sag or creep over time, causing precision changes in your prints. We think of plastic as a ridged material that never changes shape, but like glass, which very slowly but assuredly sags with time, plastic will do the same. The higher the average temperature the part is exposed to, the more rapid this effect will be.

Structural strength concerns of ABS vs PETG are a differently matter, but even so, the strength of plastic parts diminishes as the ambient temperatures increase. Therefore because of the higher glass temperature, ABS will generally outperform PETG in an elevated temperature scenario.

RE: Voron ABS parts with PETG as alternative

Those Voron printed parts are sold as ABS, can I opt PETG for ABS parts? At least for the Voron build. I did some search, these materials are both know for their strength and print at similar temperature. Is there a specific reason they have to use ABS?

I would not. Like mentioned in post 2, PETG will get soft and fail. Use ASA, ABS, or PC Blend instead.

--------------------

Chuck H

3D Printer Review Blog

RE:

Those Voron printed parts are sold as ABS, can I opt PETG for ABS parts? At least for the Voron build. I did some search, these materials are both know for their strength and print at similar temperature. Is there a specific reason they have to use ABS?

If you like to know more about the "why", the Voron team has an overview why you shouldn't use other material then ABS (or ASA). They don't recommend PC

RE: Voron ABS parts with PETG as alternative

I saw a youtube video a while back where a guy had used PETG in his Voron and it didn't work out well at all.

RE: Voron ABS parts with PETG as alternative

I saw a youtube video a while back where a guy had used PETG in his Voron and it didn't work out well at all.

Nope. PETG will not handle the enclosure well.

Those Voron printed parts are sold as ABS, can I opt PETG for ABS parts? At least for the Voron build. I did some search, these materials are both know for their strength and print at similar temperature. Is there a specific reason they have to use ABS?

If you like to know more about the "why", the Voron team has an overview why you shouldn't use other material then ABS (or ASA). They don't recommend PC

PC will work, but it is tough to print and more expensive. Heck, I would print extruder and hotend parts with Ultem, but few can handle that job.

--------------------

Chuck H

3D Printer Review Blog

RE: Voron ABS parts with PETG as alternative

I would be carefull with PC. As far as it is written in the Voron documentation (see link above), they had a lot of bad experience with different PC brand.

Therefore I see it as a kind of a risk if you don't know which brand will work. Instead of going for expensive PC I would stay on cheap ABS. I used ABS+ from eSun (about 20USD/KG) for my parts. With the standard profile in Prusa slicer for ABS it was very easy to print in a lack enclosure. Just make sure to use an air filter (HEPA+active coal) or to have very good ventilation.

RE: Voron ABS parts with PETG as alternative

Thanks everyone for insightful replies, I decide to order the ABS parts due to the toxic flume during print.

RE: Voron ABS parts with PETG as alternative

If you build a Voron, may I recommend also adding a "Nevermore" air filtration unit to it as well? Many if not most Voron owners add one to their printer. It is exactly to drastically reduce the toxic fumes. Make no mistake, while ABS is nasty other materials aren't exactly healthy either.

Regarding PC, it is not officially recommended. I have however included some PC parts in my personal build and so far had no problems with them. I suspect there can be large differences between PC from different manufacturers, I am talking specificially about PC-Blend from Prusament here.

I printed the Mini-Afterburner body incl. motor plate as well as the bed holder in PC-Blend (the latter has been replaced in recent V0.1 builds by a metal part as far as I know). It is said that PC can crackd especially in contact with lubricant. Tests on a PC-Blend benchy smeared with lubricant did not show any change over more than a month at room temperature.

PC-Blend creates stiffer parts than the remaining ABS+ parts. That also means however it is also transmitting vibrations stronger than ABS+ parts, IMHO the main reasons why the Voron team is right to recommend ABS or ABS+. PC-Blend however survives higher temperatures than ABS/ABS+ and shows even lower creeping tendency than ABS/ABS+. This is why I used it for the extruder body and especially the motor plate which is exposed to pretty serious temperatures from the extruder motor on a Voron 0.1. ABS should handle that just fine as long as you don't print more demanding stuff than ABS. However if you want to print PC-Blend on your Voron, ABS might get pushed to its limit, also at the bottom of the extruder body close to the nozzle.

My recommendation would be, stay with ABS or ASA. Only if you want to experiment think about choosing PC-Blend for selected parts where the temperature resistance and/or creep resistance outweighs the difficulty to produce dimensionally accurate parts, the stronger transmittance of vibrations and higher sensitivity towards lubricant etc.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Voron ABS parts with PETG as alternative

I saw a youtube video a while back where a guy had used PETG in his Voron and it didn't work out well at all.

Nope. PETG will not handle the enclosure well.

Those Voron printed parts are sold as ABS, can I opt PETG for ABS parts? At least for the Voron build. I did some search, these materials are both know for their strength and print at similar temperature. Is there a specific reason they have to use ABS?

If you like to know more about the "why", the Voron team has an overview why you shouldn't use other material then ABS (or ASA). They don't recommend PC

PC will work, but it is tough to print and more expensive. Heck, I would print extruder and hotend parts with Ultem, but few can handle that job.

One could order a contract produced part at xometry (or sites like that) but I do not even want to know how much that would cost in ULTEM. Needless to say that this is overkill even for a Voron where people are more inclined to do crazy stuff. I would not want to rule out however that someone has done so already. 😉

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Voron ABS parts with PETG as alternative

I printed most of the my future Voron 2.4r2 parts from Prusament ASA, the only exception being the bottom of the extruder surrounding the hotend, where I used PA-CF11, to be on the safe side.

RE: Voron ABS parts with PETG as alternative

This part is mechanically not stressed, is it?

I heard mixed things about PA, even if CF is stabilizing it in xy orientation it does not do between layers in z orientation. Which means there can be PA typical creep even in CF infused variants, but only in certain orientations.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Voron ABS parts with PETG as alternative

This part is mechanically not stressed, is it?

I heard mixed things about PA, even if CF is stabilizing it in xy orientation it does not do between layers in z orientation. Which means there can be PA typical creep even in CF infused variants, but only in certain orientations.

I have stressed PA and PC Blend both with carbon fiber that were used to print fins for rockets. Both materials handled MACH 2 stress and heat without major warping. Both had some edge deformation.

--------------------

Chuck H

3D Printer Review Blog

RE: Voron ABS parts with PETG as alternative

I have stressed PA and PC Blend both with carbon fiber that were used to print fins for rockets. Both materials handled MACH 2 stress and heat without major warping. Both had some edge deformation.

That escalated quickly. 🤣

RE:

I was not thinking about deformation due to extreme forces but about deformation caused by moderate forces over a long time (weeks or rather months). That is where nylon and polycarbonate should differ substantially, across layer direction. within the layer the CF are certainly doing their job in both cases.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE:

This part is mechanically not stressed, is it?

I heard mixed things about PA, even if CF is stabilizing it in xy orientation it does not do between layers in z orientation. Which means there can be PA typical creep even in CF infused variants, but only in certain orientations.

No big mechanical stress. It's the mount for the hotend (in my case a Mosquito) composed by two parts held together by screws that also fix this mount to the X-carriage.

Being in close contact with the heater block, the concern is the high temperatures that maybe ASA wouldn't resist very well. PC would have fine as well I suppose.

RE:

It might work well, for all I know, I have just heard some having problem with PA-CF and creep, but others don't. With your Voron with autobed levelling you may not even notice anything even if there is a bit of creep, but with a V0.1 without auto-bed levelling it could make a difference.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Voron ABS parts with PETG as alternative

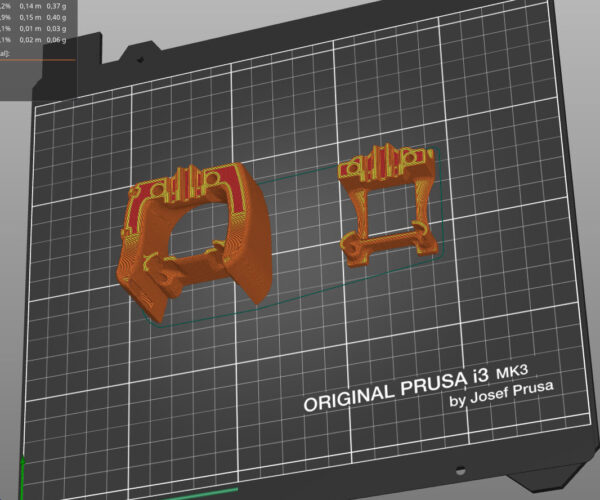

These two parts were printed rotated 90º along the Y axis from their final orientation, so the Z axis on the screen capture becomes the Y axis when they're assembled on the extruder. My guess is that the stress across the layers will follow the Y axis direction and any possible creep would affect the horizontal dimension, not the vertical.