Until recently I was a very lucky user of a Prusa MK3s

In October 2019 I purchased a Prusa MK3s as a kit for 650€ (yes, 200€ in three years). It was my first printer and I was willing to pay for a quality product. The building of the printer took me about 30 hours, but it went well.

Since then I always told everyone that the Prusa was such a reliable printer, and even purchased one for my son the next year.

I was glad to have made the good choice to buy a quality product. And last summer I buildt a luxury wood enclosure for the Prusa, because I wanted to print ABS.

It worked out really fine, and I could print ABS in high quality and without any noticable warping. No active heating, the maximal temperature I've ever seen was 41°C.

Nothing to fear.

Then came december 2022 and I got problems with print quality. I noticed that there were strange ondulations in the hotend temperature and rapidly I got the first thermal runaway. I measured the cables and wiggled them around, there was no problem.

In the first days of january I contacted the Prusa service per chat and detailed my problem.

At first I had to tell them if I had made any changes on the printer (No, I didn't), even if I had changed the nozzle (yes, I did, but luckily it was a genuine replacement). Then they told me to get the printer out of the enclosure and to do a series of test, get out the panic power cable, measure the resistances, and told me to flash other firmware.

All this was without any effect, so they told me that despite the correct measurements I should change the thermistor and the heater.

I couldn't buy it at prusa (out of stock), but luckily I found another seller which was able to send it to me with an acceptable delay.

So I changed the cables, and was very happy when I could finish a first test print of an hour in PETG. I mounted the printer in the enclosure, and after half an hour had the same issue as before. Nothing had changed.

This morning I contacted Prusa chat again, had to take photos, had to make measurements, and after some time spent on that the conclusion was that I had to purchase a new Einsy Rambo board. No possibility either to sent me a plan of the motherboard to try to fix it.

My printer has a total printing time of less than 68 days, which is not a lot when you consider that long prints easily last half a day or more. A good quality motherboard should last much longer.

So I thought that there might be a possibility to change the board or at least to have a better price. No way. Policy of guarantee.

Now I have the choice to pay 120€ plus delivery for a vintage card, to change to another (32-bit) motherboard and install klipper, or to accept a 650€ garbage.

Actually I haven't decided yet, but there are still some conclusions.

This is my last Prusa printer. It's nice when it's printing, but if you're out of guarantee and have a problem, it gets expensive. And there is no flexibility when it comes to parts that should not fail after three years.Like this motherboard. It' an old 8-bit board and you pay more for it than for an actual good 32-bit board with Wifi and all the rest.

The mosfets on the board have no heat sinks, no active cooling.

Is it that difficult to construct things that you can repair? I recently purchased a mosfet with octocoupler for another project in china for 1,21€, which could easily handle the hotend, but I will never be able to connect it to the Einsy board. There is no detailed documentation.

They tell you that there is no problem in the enclosure, that the board can handle higher temperatures .

I doubt it. My problems came after about 10 days of printing time in the enclosure with, as mentioned, a maximum temperature of 41°C.

What happens, if the next Einsy board has the same problem. As far as I know there are no improvements like heat sinks.

Doesn't seem to be a good choice.

What do you think. Has anybody had the same problem?

Have a nice day

RE: Until recently I was a very lucky user of a Prusa MK3s

I feel your pain but not sure what to say aside from that my two Mk3S have been running in LACK enclosures forever with no issues. I never bothered to relocate the LCD panels or power supplies, everything is still on the printers. I see temperatures go up to 36, 38 degrees or so when printing ASA or PC. I print ASA and PC less often than PETG or PLA but my wild guess is it's been probably close to 40 days for those filament types, and you didn't mention if your 68 days total was all at high temperatures. At this point it seems you either should cut bait and try to sell it for parts or bite the bullet and buy a new board. Hopefully you just got a lemon. But yeah, I certainly expect a board to last that long without any issues, and 40 degrees doesn't feel too high to me given the usage patterns you described.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Until recently I was a very lucky user of a Prusa MK3s

Thanks for your kind answer. I think it was about 10 days of printing time in the enclosure, the system was perfectly running, and this problem came out of nothing. What is embarassing is that I was finishing an (for me) important project, which now will be delayed.

As I didn't had something to loose, I tried a resoldering yesterday evening in the oven, first 150°C, then 190°C for 10 min. It went very well, and I was able to print for one hour and a half, but the print stopped about five minutes before the end with thermal runout :-).

I tried another 210°C which was too hot, it partially melted the plastic, but the motherboard still worked. Unluckily there was no effect on the issue.

If you want to bake the board, get out the orange plastic part, it melts at 190°C 🙂

I really hope, that I'm the only one, but I doubt it. There were former discussions concerning the mosfet of the heat bed, I belive. This problem should not be that new to Prusa. And that they don't want to look closer at this problem is really dissapointing to me.

Have a nice day

RE: Until recently I was a very lucky user of a Prusa MK3s

Just an update on this topic:

I purchased a SKR3EZ with EZ2209 drivers and a cable set from Caribou3D (and a TFT35 colour touch display, because now I can 😎 ). I needed two 24V fans too, but I had them laying around.

It took me some time, because I decided to install the board outside the enclosure, which needed a lot of crimping. And the dimensions of my board are not the same as the Einsy. You can get other boards of the same dimension and even with the same connectors, if you want.

Thanks to PrusaAIO at Github installing Marlin was easy. You choose your options, compile the firmware and your good to go. Youtube helped me a lot. And with the cable adapter set no real problem to convert the connectors. The only cable I had to cut was the filament sensor.

It prints PETG out of the box really well, and I haven't begun tinkering yet. And I now can change whatever I wantvdirectly in the firmware. Nice. Very happy with it.

On the other hand you loose some basic features, but I don't need an assistant for the first layer (any more 😊).

So if you are in my situation with a broken board out of guarantee, upgrading to a 32-bit system and installing Marlin might be an alternative at a lower price.

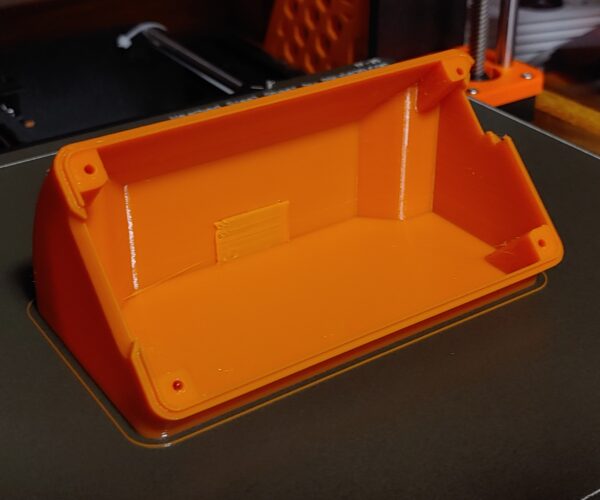

the picture is PETG out of the box, I only did first layer and PID tuning