The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

I was lucky to score two spools of the new filament before it went out of stock. I got it today and have been playing with it using the updated PrusaSlicer profile. There's a strange thing - on the print profile, the first and subsequent layer nozzle temps are set for 285ºC with autocooling set at 20% fan speed min/max (30% for bridges). But while printing after some time (I don't know when it changed) the nozzle temp is now set at 260ºC and the print fan is off. This is not an error with the printer - I tried it with 2 other MK3s+ and they all act the same. Is there an override making the temp drop to 260ºC and turning off the fan in the stock profile? I normally wouldn't question Prusa-supplied profiles but at these low temps I think there will be a problem with layer adhesion. And without the fan overhangs are going to look ugly.

Best Answer by MileHigh3Der:

@bioluminous

maybe put your ducts in a row to increase layer time.

Sorry, had to be said ;).

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

FWIW in Prusaslicer on the Filaments tab\filaments item you have the option to set bed and extruder temps for first and subsequent layers. I don't have the filament but I looked at the profile, extruder both 285 and bed 110/115. Perhaps you missed a filament profile update?

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

I haven't had that problem, but using the default profile without changing anything causes the filament to not bridge at all. I assume the temp needs to come down a bit.

It's pretty thin stuff. I'm hoping the temp can come down to bridge and still melt sufficiently.

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Apart from the concerns - how are the prints turning out. What plates are using and have you needed release agents.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

@john-6

Meh, the default profile needs some work. Parts look very ugly on even moderate overhangs. Seems to need more cooling than is in the profile. I was hoping for a more ready-to-go experience cuz I don't like spending time trying to tune filaments. Build plate adhesion is good on textured. Prints are still a little tight on the plate after cooling but not too bad. No release agent used though it did come with glue stick.

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Im wondering where you got the profile from as Prusa hasn't released one according to technical chat and in any even it isn't in the config profiles.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Im wondering where you got the profile from as Prusa hasn't released one according to technical chat and in any even it isn't in the config profiles.

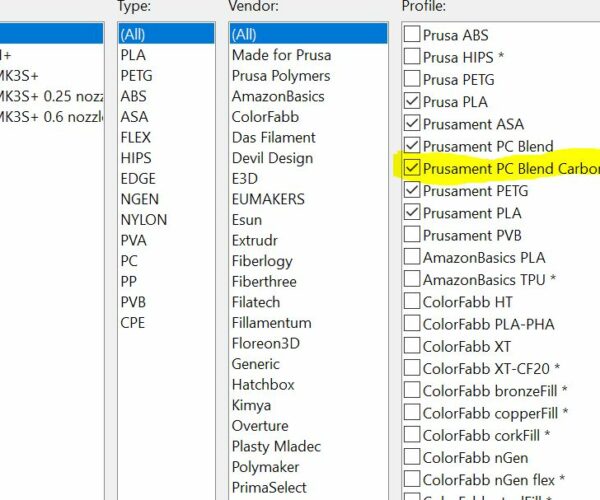

I see, and installed, the profile in/from config wizard

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Interesting as it doesn't show up on mine and technical chat says the same thing

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Perhaps you missed a profile update? "Check for updates" option under "Configuration" tab. I guess there's a log of updates somewhere, anybody know?

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

@bioluminous

How big of items are you printing? I find that with ‘goopy’ resins like Nylons, I need a fairly long printer-per-layer time or it gets kind of ugly. Attribute it to the material staying hot and flowing. I don’t want to use the fan for much, since it could cool down the material too much.

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

@milehigh3der

Thanks for the suggestions. I'll fool around with some settings on the profile.

I have not tried tuning it yet. The "Slow down if layer print time is below" setting is set at 20 seconds and the "Min print speed" is set at 15 mm/s in the default profile. The fan speed is set at 20% min / max with 30% for bridging. But I haven't found the print fan to turn on at all for the duration of the prints. I agree about keeping fan to a minimum especially since this is supposed to be more of functional filament rather than a pretty one.

The prints I'm trying are larger parts like ducts. Kind of like the part that Joseph showed on the last Prusa live YouTube.

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

@bioluminous

maybe put your ducts in a row to increase layer time.

Sorry, had to be said ;).

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Had any more success in the prints. Also I can confirm that once the nozzle hits 285 it stays there

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

Cooling fan is enabled only for layers below 10 seconds (and for bridges). Cooling greatly reduces layer adhesion with this type of filament.

System profile for this filament was released immediately after PC Blend CF release. You need to install configuration update. The nozzle is never set to 260C with this profile.

RE: The new Prusament PC Blend Carbon Fiber and PrusaSlicer Profile

The issue I was having with temp being reduced to 260 I traced to an incorrect number I set in Repetier Server, the device I use to control all my printers. I didn't realize the server resets temps, thought it just passed the gcode onto the printer unaltered. I think the same thing was happening to the fan.

It prints correctly now at 285 with fan at 20% if under 20 seconds layer time.

What I have discovered is that this filament is best used for larger, less detailed parts. I can print outside of an enclosure with no warping at all. But if I try printing smaller, more detailed items, they don't look very good, especially on layers that have shorter times. Printed parts with this filament makes it feel almost like it's made out of ceramic. The parts have an interesting sound and feel to them.