Texture transfer to printed surfaces

Discussing about powder coated sheets, I mentioned in an earlier thread that I really like the textured finish it gives and the fact that it removes the glare more than anything else (and yes, I'd love to be able to purchase one too ;)).

I use PETG a lot for it's properties, but the shiny look it has is perhaps my least favorite aspect of it.

So I was thinking two things:

- What about printing on sand paper? Has anybody tried this approach yet? Good quality sand paper doesn't lose it's grain easily, and 80 grit seems about the right coarseness to match the powdered sheets.

- I was also thinking about textured glass, although I suspect it's actually not rough enough to remove the sheen of PETG. But the effect might be interesting.

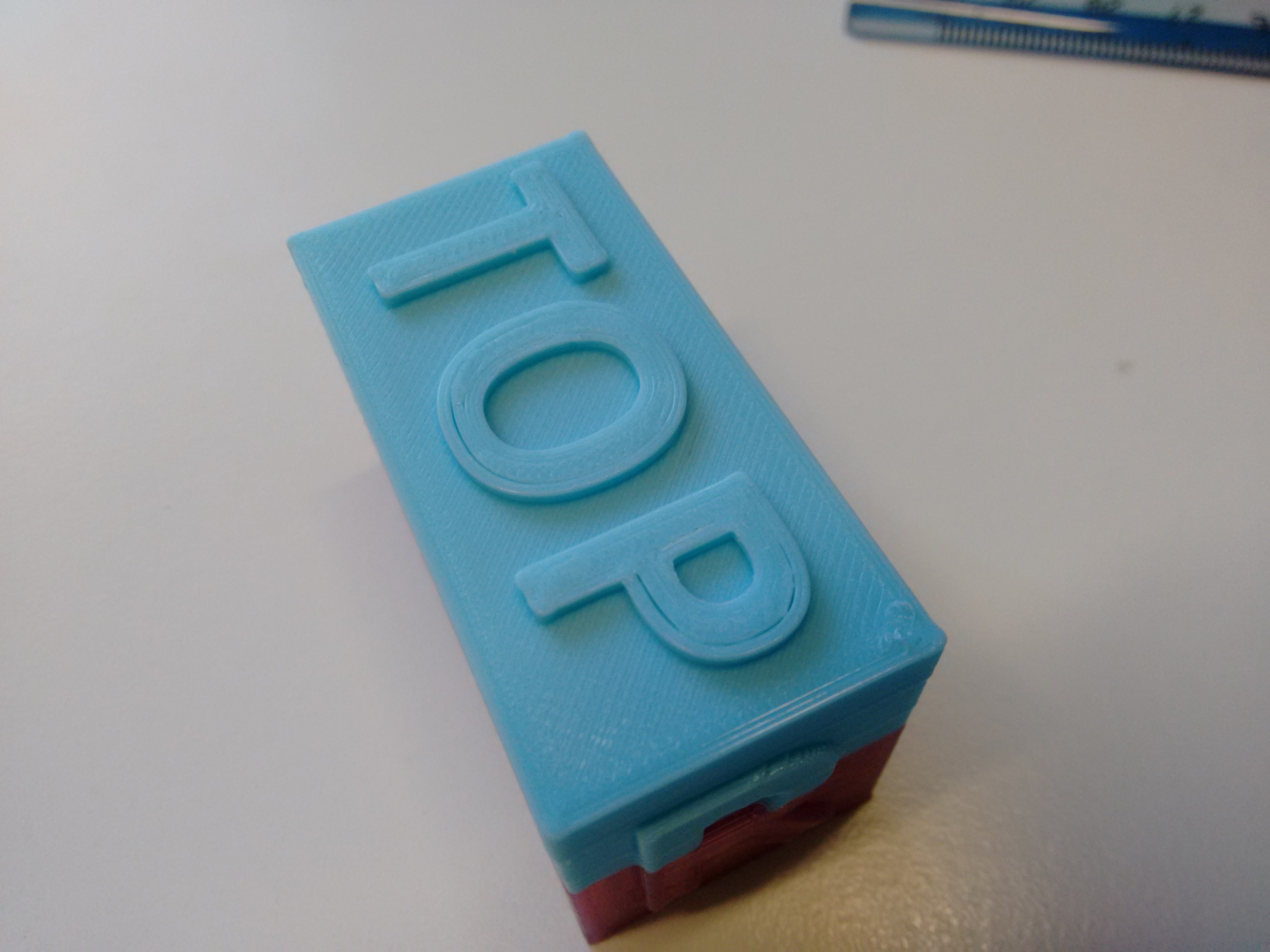

While thinking about glass, I simply tried the oldest trick in the book: heat texture transfer from a piece of glass to a PLA block. Here's a PLA block I printed with some left-overs to give it a try:

the top side is shown. As the texture "donor" I used a microwave oven plate, which had a texture I liked.

Here's the best result I got, which is on the top face:

Definitely promising. A few notes on the approach:

- The plate was slowly heated on top of an electric stove while monitoring the temperature with an IR meter

- I did several tries on the various faces with various times/temperatures

- Best result was with glass at ~140C, piece applied with moderate pressure for 3 seconds and quickly removed

- Dimensional accuracy wasn't affected (height unchanged when measured with a vernier) thanks to the quick action

After testing, I wouldn't use glass again as the texture donor. As you can imagine, PLA sticks a bit too much to glass and it does melt if left too much or with higher temperatures.

Large flat surfaces are tricky. The front side was "ok" towards the left, but I didn't apply the same pressure on the right, showing a reduced effect.

The obvious advantage of this approach is that you can modify any side of a printed object, not just one face. I think it would be worth investigating 🙂

Comments?

Re: Texture transfer to printed surfaces

How about a hotplate with a sheet of textured aluminium sheet on it:

https://theinsulationshop.co.uk/products/aluminium-flat-sheet?variant=3728195329&gclid=EAIaIQobChMI_K-pk5fw3wIVhZztCh3CVQwYEAQYAiABEgKsGvD_BwE

A suitable release agent may need to be sprayed or may not, I really don't know.

The part would simply be pressed down onto the heated aluminium sheet, I've had a quick look and there are plenty of other designs available so you could just swap the sheet, heat up the hotplate and press your part into it.

Hmmm, I quite like this idea, using a heated bed with it's own temperature controller.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Texture transfer to printed surfaces

Do you think a release agent would be necessary at all for aluminium?

I have some in a hardware shop nearby, but by memory none have a texture fine enough.

There's a CNC shop which might have something else, but I won't be able to go there before the next week.

Re: Texture transfer to printed surfaces

Just had a quick read around the net and it seems petg does not stick to aluminium at all well 😀

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Texture transfer to printed surfaces

Interesting technique. I defintely prefer the textured bed. It just seams easier.

--------------------

Chuck H

3D Printer Review Blog

Re: Texture transfer to printed surfaces

So the textured alu sheets I've seen are not really suitable for the task. The texture is too big. The finest I've seen is still twice as large as the grain size you find in your typical microwave oven plate.

Re: Texture transfer to printed surfaces

I know, what about a cheap cast iron pan!, they usually have a sand mould finish.

https://www.canstockphoto.co.uk/cast-iron-7299918.html

You could just heat it up to the right temperature, checking temperature with a thermal gun and press your parts into it, job done!.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.