RE: Static shocks and garbage letters on the LCD screen

From Joan:

"the issue with 3D printers is that we don't fully know whether you are discharging to the printer, or whether the printer is discharging to you... "

This is an interesting observation. I would assume the controller board ground is directly linked to the PSU so that would be OK.

But considering the extruder assembly is floating could there be a possibility that during a print the spool, filament and extruder do accumulate a charge from static electricity from all the rubbing, much like a van de Graff generator?

I'll see if I can get my Keithley 617 electrometer connected to the extruder and see if it's collecting a charge.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Static shocks and garbage letters on the LCD screen

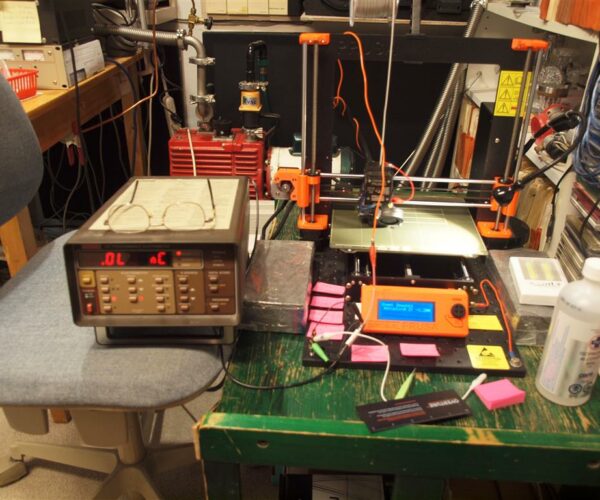

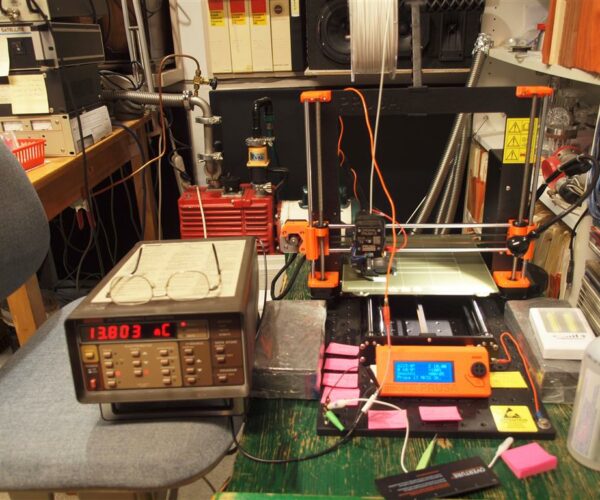

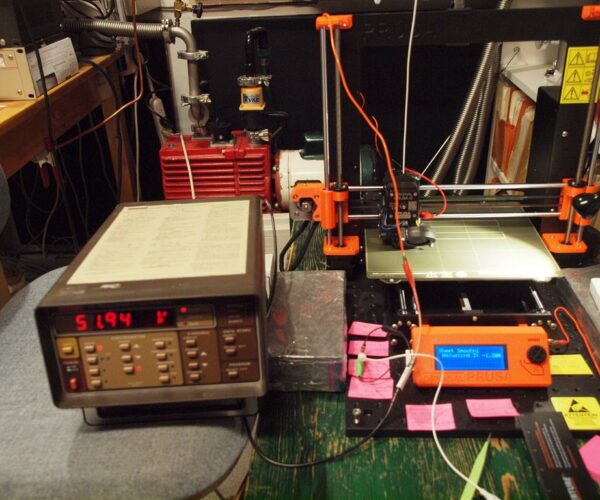

OK. Just did a quick experiment with a Keithley 617 electrometer.

I connected the extruder cooling find with a flexible wire following the ombilical from the controller board to the 617 input.

I used the first layer cal to test. So one layer only with the zigzag and the stamp.

There is of course some fluctuations near the zero point but no real changes during the bed heating and extruder heating up.

There is no difference during the levelling pinda process either.

However the moment it started to extrude the filament things happened in both nanoCoulomb mode and in voltage mode.

In Coulomb mode it went overflow half way through and with an extra 10nC for a total of about 40nC.

In voltage mode it went to about 50V and to >100V in another.

Putting my hand on the spool (PLA) or rubbing the filament greatly increased the readings. Looks like the filament accumulates electrostatic charge and delivers it to the floating head to accumulate.

Could it be that with dry filament it is possible to have a high enough voltage to cause a spark to conduct an ESD to the control board via breakdown in the thermistor or heater? On a long print this might cause resets or errors at random intervals.

OLYMPUS DIGITAL CAMERA

OLYMPUS DIGITAL CAMERA  OLYMPUS DIGITAL CAMERA

OLYMPUS DIGITAL CAMERA  OLYMPUS DIGITAL CAMERA

OLYMPUS DIGITAL CAMERA

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Static shocks and garbage letters on the LCD screen

could not append pix in previous post.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Static shocks and garbage letters on the LCD screen

Interesting data, and not unexpected. I wonder if the developers have done this sort of testing. I also wouldn't be surprised to find this sort of ESD occurring on other modern printer designs where moving parts are electrically isolated for long periods.

My other printer is older and a much higher % of conductive materials were used in its construction. I never get zapped when I use that one.

I also agree with Joan in that some effort may be required to electrically connect the conductive parts on this printer. The paint they use is tenacious enough to insulate some of the screws. I also had to remove paint to get all the legs electrically connected.

I love it when I see working people using their trade to seek out the why things happen and creating solutions instead of accepting excuses. I'm fortunate to work a team of smart people that spend the time to understand why a thing happens, before putting any effort into changing it. It's a mindset that is rapidly being lost in the general public. That's why I pay a lot of attention to this forum. Because I get to see so many people here that have avoided the "if its broke just buy a new one" mentality so many of our contemporaries have accepted. I love it.

I've managed to mitigate most of the ESD issues but I still get the occasional LCD display waver and alien speak when I touch the selector knob. Fortunately it recovers quickly, but it's still concerning.

Nice pic, I had forgotten what a beast that Keithley is.

RE:

@egar How come doing what you suggested would solve the problem? Didn't Prusa took the grounding into account when they designed the machine?

I have done what you suggested. Is it better if I remove some of the paint at the area where the ends of the cable connect to the printer's frame and PSU?

RE:

Sometimes when I removed or put back the PEI sheet, the LCD screen still turned blank (blue background with nothing) when the heat bed touched me via the PEI sheet. One time garbage symbols showed up.

RE:

Grounded my extruder assembly and the stepper with a small wire. On the cooling fins I used a small beryllium-copper springy loop for RF shielding. That way it can be removed at will to rotate or change the extruder. The wire goes on the ombilical and secured with tie wraps.

Then goes to a 100k resistor just in case I short out a heating or thermistor wire while changing the nozzle. That is then bonded to the frame. I verified that the frame is a ground via the PSU.

I did not ground the build plate at this time and hope that will not be needed. Don't forget that ESD discharges are cumulative on the semiconductors protect circuits.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE