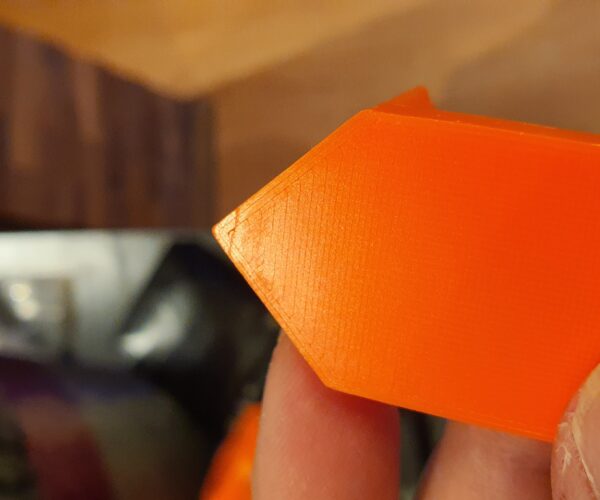

Silk PLA Filament Crack

Hello,

Has anyone seen cracks like this, or know what causes it??? This is inland (eSun) Blue Silk PLA Filament ( https://www.microcenter.com/product/625953/inland-175mm-blue-silk-pla-3d-printer-filament---1kg-spool-(22-lbs))

I am using an i3 MK2S with generic PLA settings. I have never had a print that cracked like this. This is the first time I have printed this filament, and every print has this issue. It is NOT associated with where I take the print off the bed. You can see that the bottom right image is showing some other issues, so I am trying to print with the initial layer cooler (210). We will see if that helps.

Best Answer by captclearleft:

Thank You all for your responses. I guess it is lifting of the corners. After printing a regular Inland (eSun) black PLA... and the same thing happening, I am guessing it is not the type of PLA itself. Plus I put the Silk PLA on my MK3 MMU and it prints fine. So, I tried a few of the suggestions above...

THE FIX:

I turned the head down on the initial layer from 215° to 210°. That fixed it the issue.

I am not sure why I have just started seeing this issue on my MK2S, but perhaps the PLA compound has changed, and I didn't recognize it until printing these larger prints... Again - THANK YOU - Happy Holidays!!!

RE: Silk PLA Filament Crack

The "cracks" in the corners are just marks from the print lifting it's corners from the bed. I'm 99% sure of it as I have experienced this with different parts. Sharp angled corners + taper increases the chance of the print lifting up.

The curling of the first layer (bottom right) is usually caused by too much heat in that area and poor adhesion.

Cheers

RE: Silk PLA Filament Crack

@vladv

try 70C on the heatbed!

I don't know how you clean your Build Plate,

I wash mine well, with Dish soap and water, rinse well with hot water and dry immediately with Plain Paper towels...

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Silk PLA Filament Crack

@vladv

try 70C on the heatbed!

I don't know how you clean your Build Plate,

I wash mine well, with Dish soap and water, rinse well with hot water and dry immediately with Plain Paper towels...regards Joan

Hi Joan,

I'm sorry but I'm not the OP. My first reply was under moderation and I think that is why my second reply made no sense. I was giving examples of poor bed adhesion that my generate "cracks" in the corners when they are actually a result of the corners lifting up during print.

Anyway, thanks for the advice. I clean my bed with 98% IPA and has worked well. Didn't need to clean it with soap or water.

Cheers.

RE: Silk PLA Filament Crack

@vladv

Rumor has it that some makers (no, not me, I swear) eat Haribos while working with the printer.This can cause sugar to get onto the printing plate. Sugar is not dissolved by alcohol, so from time to time you should wash the print bed with soap solution to remove the sugar that inevitably sticks to our hands. The especially if you have problems with adhesion. If you do not have such problems, you should consider yourself lucky, and continue everything as before.

But I also have problems with Silk PLA from Sunlu: I can not print it with the Mini, but with my MK3S without problems. But that should be discussed elsewhere?

Best Regards, Klaus

RE: Silk PLA Filament Crack

Thank You all for your responses. I guess it is lifting of the corners. After printing a regular Inland (eSun) black PLA... and the same thing happening, I am guessing it is not the type of PLA itself. Plus I put the Silk PLA on my MK3 MMU and it prints fine. So, I tried a few of the suggestions above...

THE FIX:

I turned the head down on the initial layer from 215° to 210°. That fixed it the issue.

I am not sure why I have just started seeing this issue on my MK2S, but perhaps the PLA compound has changed, and I didn't recognize it until printing these larger prints... Again - THANK YOU - Happy Holidays!!!