RE: Review: Prusament PC Blend

@charles-h13

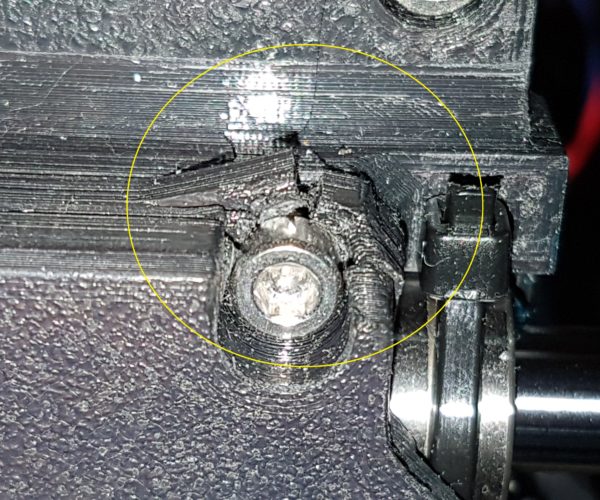

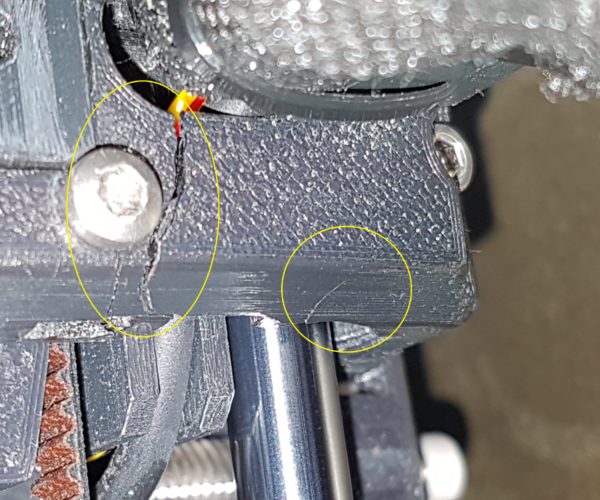

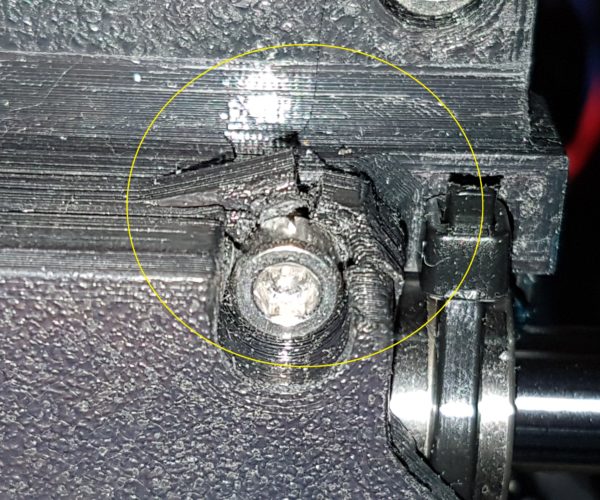

Thank you very much for your feedback. I have just ordered a roll from Prusa and will test the material extensively. I had little luck with the polymax PC. Unfortunately the printing parts (MK3 extruder) broke apart after a few months.

😕 ☹️ !

Wow breaking PolyMax PC is a big deal, your printer must go crazy fast haha.

Have you annealed your parts or printed it in a heated chamber?

RE: Review: Prusament PC Blend

I did print my parts in PC blend at 40% infill. I wanted extra strength.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

@3dprintingscience

Printed in a case at 45 degrees C. (275/105).

I have been warned that the additives in this PC can be destructive - I have experienced it and I am not the only one.

For this reason I am now testing Prusa PC Ware.

Try it and see 😏

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Review: Prusament PC Blend

OK, it's a good thing I have spare parts (original and another one). Only in PETG but still...

RE: Review: Prusament PC Blend

@karl-herbert

I print at abotu 90-104 F or 32-40 Celcius. I never print outside an enclosue. I crack the door for PLA. The rest is enclosed and Temperature controlled.

I am building my printer farm building or using a shipping container this after the Winter. I have to get them out of my house.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

@charles-h13

I would rather run the printerfarm in a studio than in my own house. My wife would not agree with that at all. Especially the SLA printers are a bit more problematic in terms of odor.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Review: Prusament PC Blend

@karl-herbert

Understood. My wife is the same way. I am currently printing in an apartment studion but will be moving back home this summer.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

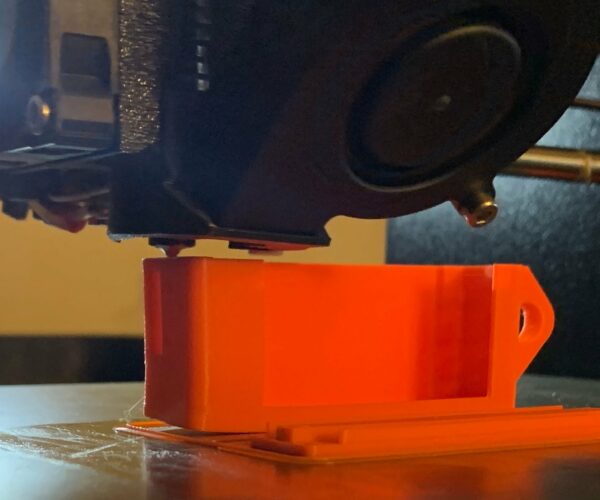

i bought 2 spools - orange and grey .

here's my short review ...

VERY easy to print , compared to any other pc i tried .

its almost as easy as pla .

i printed on glass with magigoo (regular , not pc) without any adhesion or warping issues (printed in 50c closed chamber with 125c bed)

printing temp - tried several settings , didn't see any improvement past 265c on layer adhesion , so 265 it is for me .

layer adhesion - not as great as pla ,of course . had to crank up extrusion multi up to 1.1 , this way got best layer adhesion / part quality ratio , extrusion width set at 0.48 with 0.4 nozzle .

printed 100% infill parts with it and no warping , which is great - much easier then abs .

and the best thing for me - no need to dry it (at least few days) ! printed several days without drying and without any issues .

heat resistance - tested in boiling water - no issues (about 2x7x3cm part).

don't know how the additives will effect the parts on the long run yet .

and the bad , as always - prusa shipping 🙁 . payed 70$ shipping for 2 spools + local customs , blah .

RE: Review: Prusament PC Blend

I printed parts for my mini. I can't get larger parts not to warp.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

@blingstatus

Could be - but it could also be an issue of not clean enough build plate, having no enclosure for the printer, ...

Starting in the order:

1) Cleaning

2) z height

would be my suggestion. It can also help to use a brim which helps to keep the part on the build plate.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Review: Prusament PC Blend

@clemens-m

I concur with clemens-m. Try Z height and clean the bed. The fact that you are using gluestick, Z might be the right place to start.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

Thank you guys, I will report back once I try again after adjusting the z-height.

RE: Review: Prusament PC Blend

Could bed temp be the reason why larger object are not sticking as good on the mini?

What bed temp are you using for the mini when printing PC?

Do the temp go as high as the MK3s?

Prusa says it only goes to 100 on the mini, while they recommend 110 for PC.

Then again some claim to have gotten higher that 100 on the mini.

Or, could the mini bed temp be less consistent than the Mk3s - ie hottest in the middle and cooler towards the edges?

Just speculation 🙂

(I've only got the Mk3s myself, but ordered a mini so I should be able to test for myself in a month or two 🙂 )

My printers: Mk3s / Mk3s clone with +upgrdaes (you know SPinda and all that good stuff) / Mini+ / Ender 3 v2

RE: Review: Prusament PC Blend

@loadinglevelone

Bed temp is absolute one reason for poor adhesion. An enclose is also recommended.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

@loadinglevelone

The Mini's power supply delivers only 160 watts. This is very limited and due to this fact the bed can only be heated to 100 degrees C., the MK3 heating bed however over 120 degrees C.

If PC does not stick, I would try Kapton foil or an adhesive/glue or/and or set first layer lower.

Warping and stringing cannot be eliminated 100%.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Review: Prusament PC Blend

@karl-herbert

I will try that tonight. Never thought about Kapton tape. I was able to get adhesion but it was a struggle.

--------------------

Chuck H

3D Printer Review Blog

RE: Review: Prusament PC Blend

One other thing I'm going to try the PC Blend for, just as soon as a few prints de-queue, is for a small bracket which will hold a 7805 regulator and heatsink assembly to the side of a project box made of PETg.

I've measured the temperature of the heat sink when in full operation and it runs between 28C and 32C or so. (The 7805 can reliably run up to 100-120C or so.)

While I don't think the assembly would get hot enough to deform the PETg, I have almost a full spool of PC Blend and this is a case where some additional heat tolerance may be beneficial.

RE: Review: Prusament PC Blend

My printer is in a cupboard, which I usually leave the door open a bit, I'm thinking this might work ok for printing PC blend if the door is shut. There is a lot of wood in there though so hmm.. perhaps I need to invest in a proper enclosure... in any case my main question is, if PC blend is so good, why doesn't Prusa print their parts in it rather than PETG? I see that PETG parts are melting when printing PC blend yet there is no mention off this on the PC blend pages themselves.. it seems that you just find this out after having tried :S

So I think I should reprint my parts in PC blend too, but then the very fact of printing the will melt the current PETG parts :S So I guess print spare PETG parts first? Urgh... or perhaps just source someone else to print them?

RE: Review: Prusament PC Blend

... if PC blend is so good, why doesn't Prusa print their parts in it rather than PETG?

Its a cost/benefit thing. PETG is cheaper and more than adequate for most of the parts.

The only parts in risk of melting are those in close proximity to the hot end - ie the fan shroud, pinda/fan mount.

I've read that the fan shroud on the Mk3s is printed in ABS for this very reason, but why they chose PETG for these parts on the mini is unclear.

My printers: Mk3s / Mk3s clone with +upgrdaes (you know SPinda and all that good stuff) / Mini+ / Ender 3 v2