Prusament PETG V0

To my surprise, there isn't a section on this forum to discuss Prusament, even though they have separate boards for just about every other product they sell.

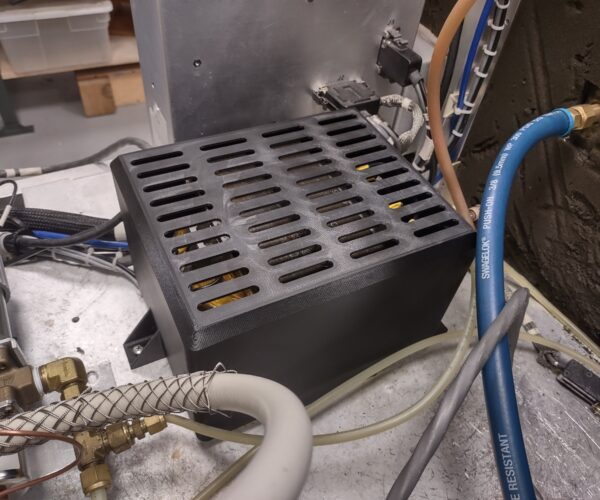

But yeah, I've actually been trying to find a suitable Flame Retardant filament to make air deflectors that go around some high voltage components that we need to be made of UL94-V0 material, so this is awesome that Prusa seems to be the first to actually have UL fully test it and give it a certification. And thankfully it's a material like PETG witch you can actually print large flat functional objects relatively easily without worrying about warping.

With all that being said, This now brings up a bit of a wish list I had for a self extinguishing filament, in order of how soon I'd like to see them.

- Certified profiles for the MK4, and XL. My work just started using both of those to replace our LULZBOT Taz 6, and we don't have a MK3s, Though I imagine The profile won't have to change and it can be retroactively applied if ULs testing goes well.

- Glass Fiber version to increase Tensile Strength, and Dimensional Stability. Not Carbon Fiber as they can actually increase Flammability, but Also make it slightly "conductive" and therefore unsuitable for use around High Voltage. GF would also increase the heat deflection temperature which is also a likely scenario if a cooling fan fails.

- Extend the UL Certification to 746C for use in Electrical Equipment (Comparative Tracing Index, Dielectric Strength, HVTR, ect...)

- UL94 V0 Glass Fiber Nylon. Nylon already has the print it dry requirement, and with Glass Fiber Reinforcement, it's Heat Deflection Temperature would be well into 100+ Degrees, and it should have no trouble keeping Dimensional Stability if you have your printer enclosed.

But Yeah, those have been my thoughts for the Ideal 3D printing material for Enclosures and Parts around High Voltage.

RE: Prusament PETG V0

Could you provide the details of this print?

1. What printer are you using?

2. What nozzle temperature did you use?

3. What bed temperature?

4. Anything else of interest?

I'm trying to print using another brand of flame retardant PETG and it has been a nightmare so far.

RE: Prusament PETG V0

I tried to print an electronics enclosure using Prusament PETG V0 (Natural colour), and also did not have success.

I've ordered a dryer (which I've never needed before) because I think the filament is too wet based on the failures. I print primarily with PETG normally and haven't had failures like this one.

The issues I ran into (MK4/0.4noz/0.2layer, satin sheet, standard PETG V0 profile):

- I used organic supports for the flange around the edge of the box. The first layer had several of the support "disks" become partially unstuck from the print sheet. Looking closely it appeared the filament pulled up the disk at the point where the print head left the disk to print the next one - 4 of these disks came up the same way. But only 4... I was watching the initial layer, and when I saw this I decided the temperature was too low (the profile calls for 20-30C lower than normal PETG) so I raised it to normal PETG levels.

- On later layers, maybe after 10 or so, I noticed one or two small block "blobs" in places. I managed to break them off before they caused a print failure. I decided my temp increase might not be a good idea, so I cleared my override and the printer returned to the profile settings.

- About 80% into the print, a blob formed on the top of one of the organic supports and it was knocked off the bed. Two more followed before I paused the print. I tried a few ways to rescue the print, including using glue stick to re-attach the supports to the bed (which actually worked BTW), with masking tape and paper on top to try to get the next layers of support to stick, but it just wouldn't adhere so I abandoned the print.

I ended up using "Canadian-Made PETG+ Black" for the enclosure and it printed correctly with no issues. Since this is a hobby device I'm not forced to use flame-retardant material but I thought it might be a good idea. If I can successfully print the V0 after drying I will use it.

Prusa MK4 since Jan 2024, MK4S/MMU3 since Jan 2025, Printables: @MikeB_1505898

RE: Prusament PETG V0

I'd definatly reccomend a dryer for this filament. Because I use it at woek and we print things like nylon that really need drying, and they said in the release that this is more mostier sensitive then normal PETG I dried it right off the bat, cause it's suprising how not dry some filaments can come in a vaccum sealed bag with dessicant. So right off the bat I got great print results. But it definatly does absorb mosture faster, or at least is more effected by moisture more than other filaments.

But when it's dry the prints look better than PLA. there dimmentionally accurate, and they have a really nice matte finish that actually hides layer lines really well. All the printing I've done with it is for work, and so I don't have any parts on me to take pictures of until after canada day long weekend. but I have some really nice parts I've printed with this stuff.

Also, at my work we have not just a drying oven, but a vaccum oven wich can get the mosture content of a spool to below 5% and the printers are all in an enclosed shelf with a full size dehumidifyer running continuously, so theyre basically never above %30 humidity. so I'm a bit spoild when it comes to having an ideal printing enviroment.

the printers used are a MK4 anfd XL

Hope this helps.

RE: Prusament PETG V0, drying temperature?

what temperature to dry this at, and for how long?

any info appreciated, thaknsw

RE: Prusament PETG V0

I have a big problem with this filament and Prusa XL. Nozzle always pickup blob around nozzle. I hvaen't an idea, I tried Dry filament, decrease flow to 90%, I tried 230-240 degrees and not helped me! I'm devastated :/ Which setting You use? Can You send me a profile? Which speeds, temp, and flow? :/