Prusament PC blend carbon fiber dimensional accuracy of printed parts

Hello community!

I noticed that printing with stock profile Prusament PC carbon gives me dimensionally printed part on the higher side of tolerance. When printing with every other type of material I kind of have results around 12.45mm for a target of 12.5mm. When loading the prusament PC carbon I'm having result more in the range of 12.82mm.

I first noticed this when I tried to assemble my upgraded part for the mk3s+ extruder. Some parts doesn't fit together. I had to sand to be able to "slide fit" some parts. I tried and printed the same parts in PETG and there is absolutely no problem.

One parameter that could affect the default profile is that I use a Tungsten carbide nozzle. I had to reduce the temperature to 280 (even at this temperature it prints bridges badly since the material comes out too hot) and my layer adhesion is really good.

I've modified the extrusion multiplier from 1.04 to 1, which gave me better looking part (doesn't look over extruded) and now my accuracy is around 12.75mm. But this road don't quite fixe my problem because I went all the way to .85 extrusion multiplier and clearly my part now looks underextruded. My accuracy was better tho at 12.55mm.

So yeah I'm starting to wonder what could gives those result and what are my other options? Next on my list is to print a temp tower to see if the problem is only the fact that using a tungsten carbide I don't have to compensate too much for the temperature.

Other than that I read on the prusament PC blend carbon fiber page that you can print on a clean powder coated PEI sheet using IPA. This left me with a partially peeled off PEI sheet. I waited for the sheet and the print to be at room temperature. Now I use a ridiculously small amount of glue on the powder coated sheet to make sure it doesn't damage it again, so be careful with that!

I hope somebody had the same problem and know the fixe 🙂

PCCF tolerance

Hi Gab. I have printed the extruder to one of my MINI Bear (Mirrored MK3 extruder R4) in PCCF and it worked for me. I have not measured any parts and the only part that was a tight fit that was the little part for the steelball. But i had my last extruders printed in ColorFabb XT-CF20 and that was also a little tighter fit than with regular Prusament PETG. I use hardened steel nozzle from Prusa shop. So in my case i believed it was the carbon fiber itself that change the fitment because of the strukture itself but you can be right it change the size a little to. You can try with a hardened steel nozzle to see the difference is enough for you to. Sorry if that did not answer your question as a fixe 🙂

Steel sheet

Hi again Gab. I used a Satin Sheet and no glue. Have used a half spole and about 10-12 prints and no mark or issue yet.

Every filament is different, you have to test print, especially if measurement is important.

A temp tower will give the best temperature for looks and a little hotter is better for the print sticking to it self.

Pc blend with carbon, does this need a 5 mm or bigger nozzle (possible), search on this.

A few weeks back I printed pc (without carbon)for the first time, search on the bed , and I was told to use glue stick, for the future if you use a new filament search for it on the internet.

If you print a higher temp, possible the filament will come out faster, look if this works better. Do a few test prints, temp tower, bridging, slower speed will help to cool down the filament, before the next layer,

if you print fast on a small print it will get to hot, so print more models at the same time and lower speed.

RE: Glue stick

I can confirm no need for glue with the PCCF. I will try anything not to use glue even if long term degradation occurs

Hi again Gab. I used a Satin Sheet and no glue. Have used a half spole and about 10-12 prints and no mark or issue yet.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Poor fits

I have noticed that two parts which snap fitted with prusamant PLA is too big to fit with the prusament PCCF. I have even reduced the extrusion multiplier to 0.9 with out much benefit. It would be nice to understand what is happening as 20mm cube prints almost perfectly.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Fit parts

I should add that the parts are created using a Boolean operation subtracting one part from another, so tolerance for over size is very small but it does work for me in PLA.

Also using a 0.6mm nozzle.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE:

Hi,

Regarding the tolerance with PC-blend carbon, I tested gears (number of teeth T=20, module 3) with 2 perimeters and the standard settings in Prusa slicer and a 0.6 mm hardened steel nozzle. I had to adept my cad-model to a clearance of 0.45 mm to get the gears turn smoothly (with PLA I use a clearance of 0.05 mm) .

In the next step I changed the number of perimeters to 4, because massive teeth are stronger. I used the clearance of 0.45 mm again, but to my supprise the teeth where much too thick. Does someone has an idea why this is happening? And will the setting "external perimeters first" make a difference?

RE: Prusament PC blend carbon fiber dimensional accuracy of printed parts

I asked it in the chat of prusa and I got this answer that I am going to follow up:

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257 and use the 'Precise Method'.

I hope this helps.

RE: Prusament PC blend carbon fiber dimensional accuracy of printed parts

I have calibrated my extrusion multiplier value. I had to change the default value of 1.04 to 0.991. This resulted in an average layer thickness of 0.66 mm instead of the extrusion width of 0.65 mm for a 0.6 mm nozzle. A lower extrusion multiplier value of 0.98 resulted in an average layer thickness of 0.66 too. (see https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257)

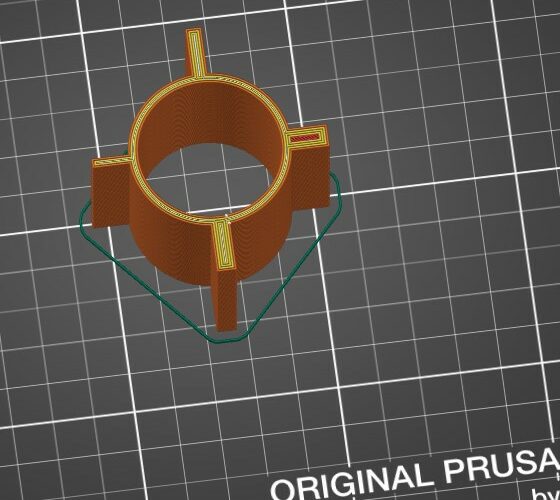

After that, I did some calibration tests with a tube with 4 different teeth on it (see picture). The teeth are 2.60, 4.00, 5.00 and 6.00 mm thick. I have set the number of perimeters to 4.

This resulted still in too thick teeth: 6.24, 5.28, 4.24 and 2.80 mm.

I did another test with the option "external parameters first" and I slowed down the external perimeter speed to 25 mm/s. This did the job: the teeth are now 6.04 mm, 5.03mm, 3.99 mm and 2.60 mm.

RE: Prusament PC blend carbon fiber dimensional accuracy of printed parts

I have calibrated my extrusion multiplier value. I had to change the default value of 1.04 to 0.991. This resulted in an average layer thickness of 0.66 mm instead of the extrusion width of 0.65 mm for a 0.6 mm nozzle. A lower extrusion multiplier value of 0.98 resulted in an average layer thickness of 0.66 too. (see https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257)

After that, I did some calibration tests with a tube with 4 different teeth on it (see picture). The teeth are 2.60, 4.00, 5.00 and 6.00 mm thick. I have set the number of perimeters to 4.

This resulted still in too thick teeth: 6.24, 5.28, 4.24 and 2.80 mm.

I did another test with the option "external parameters first" and I slowed down the external perimeter speed to 25 mm/s. This did the job: the teeth are now 6.04 mm, 5.03mm, 3.99 mm and 2.60 mm.

I too have noticed the default extrusion width for the profile results in walls which are too thick.

Your idea to slow the external perimeters is interesting but im not sure why it would reduce the extrusion width

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Prusament PC blend carbon fiber dimensional accuracy of printed parts

I think that the option external parameters first is the most important setting to reduce the over-thickness.

If dimensions are critical, with any filament, a calibration print is essential. Change the model before you change the print settings.

If you are prototyping in a cheap filament for a high-tech expensive filament final product it always pays to use a variable tolerance parameter.

Different filaments are printed at different temperatures and have different coefficients of thermal expansion, they will cool to different sizes. Inclusions, be they fibres, metal or wood fill or even pigments will modify the contraction making raw calculation difficult. Calibration is easy.

Cheerio,

RE:

I too had a bad first experience with that 1.04 default extrusion multiplier for PCCF. It is a long time I didn't change extrusion multiplier as I found the default ones quite good or at least not bad.

I used to measure only one wall width. Seeing your model, I changed my method to measure a square with sides having 4 different widths. I print at ~3mm3/s. I set perimeter width to 0.443 and external perimeter to 0.471 to get:

- 2 perimeters = 0.9mm

- 3 perimeters = 1.3mm

- 4perimeters = 1.7mm

- 5perimeters = 2.1mm

Those fixed wall wdths should be less relevant with the arachne engine.

I think your theory of changing external perimeter width to avoid over-thickness is wrong. Here how the tool paths, spacing and widths are calculated: https://manual.slic3r.org/advanced/flow-math