Prusa Engineers; Heat or not to heat

Hi all! I'm just trying to find explanation of an artifact.

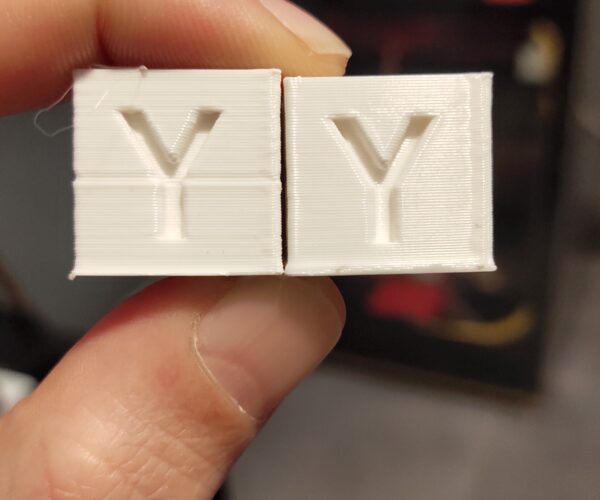

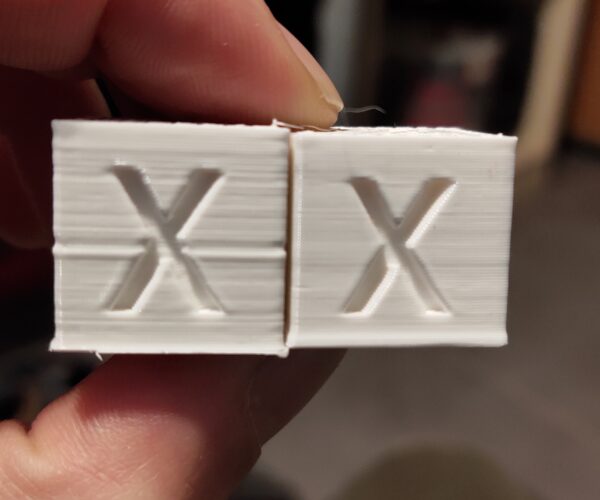

Here I have two calibration Cube printed from the same gcode, same time, same filament.

One is without heated bed.(enclosure)

One is with heating bed(enclosure, only 50c)

While I was trying to reduce the ugly lines on my prints I noticed that heating the bed worsen the surface of the prints. Some may talk about thermal expansion etc. but I have a proof that thermal expansion is not guilty as this artifact.

Actually most of the users won't care about these lines because they are not very visible if you want to look direct light.

As you see not much difference(or tolerable) 0.6 nozzle, 0.28 mm layer height

Here is shot under top of the light(noticed z height?)

Okay, now under the correct lighting lines are visible. Right one is printed without heated bed, left one is printed 50c.

One could easily say it is thermal expansion but luckily I have noticed something live with naked eye.

While printing if you turn the heated bed OFF and ON manually it INSTANTLY creates a line as seen in the middle of the left cube.

You cant explain this with thermal expansion as it is a enclosured printer and I turn it ON again in seconds. So there is no time to cool for the bed to expand or shrink. More over lines are more visible at left cube because PWM basically means ON/OFF for the heated bed and I start to believe it creates some artifacts on the surface. It is pid tuned bed stable at 50c +-0.5c

Before that I have made lots of upgrades on that printer. I thought it was extruder problem, z wobble, wiring, psu,expansion, filament etc.

Luckily I have seen it creates artifact when turning on/off the heating bed with naked eye and it is repeatable.

Not all the printers are the same so it could be related with my hardware but I mostly see these lines on most of the other users. Generally ppl advise it is z wobble or extruder problem., pid tune etc

For my side which I couldn't explain is that I'm using 500W AC heater on 500x500x4mm glass. I'm printing directly on borosilicate glass(lowest thermal expansion) and the silicon heater is under the bed. I have sepearated all the wires between mainboard and AC lines which may create some spikes and isolate them. I even used different power outlet(stable 230v) between board(psu stable 24v) and AC heater. How the hell turning off the heated bed instantly creates a hard line on the print? I tried different PSU, UPS and new SSR relay. I don't think there is too much load on the board since it is AC heater but last thing I will add an external mosfet to see if it makes any difference.

Okay I can live with this but finding an explanation becomes more important than fixing the problem for me now.

It is custom designed 0.5 m³ mt / H BOT printer, duet wifi board.