Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

This particular product came up in discussion in the recent 'Bed Adhesion' thread in this forum. I brought up the page, and it looked interesting and like it might be worth trying. I said 'what the (uh, heck)' and ordered a bottle via Amazon and it arrived today.

My go-to bed adhesive to this point has always been the Kores glue stick (after making sure that the print bed was not only merely clean but really most sincerely clean, of course) but I really have not had to use it much, except as a release agent for ABS and now for PC Blend prints.

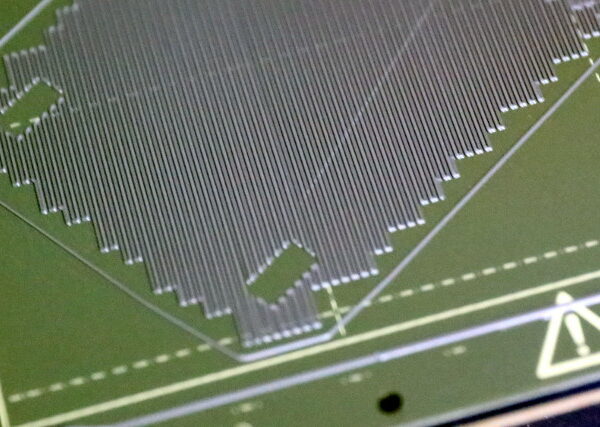

I have, however, had issues (as everyone certainly has) with getting PLA to properly stick at times. I've had one break-away, resulting it what could have been a Blob Of Doom had I not discovered it in time. I've also had one particular issue when doing PLA prints which have a particular type of support. This is where the first layer of the supports on the print bed (that small 'square wave' pattern) where it does not have much size to it. I've found that often, not always, a few of the ends/corners will not be completely stuck and will turn upward from the build plate. This is usually NBD since the second layer of support material, printed 90 degrees out, will hold it down. Still, it's been annoying.

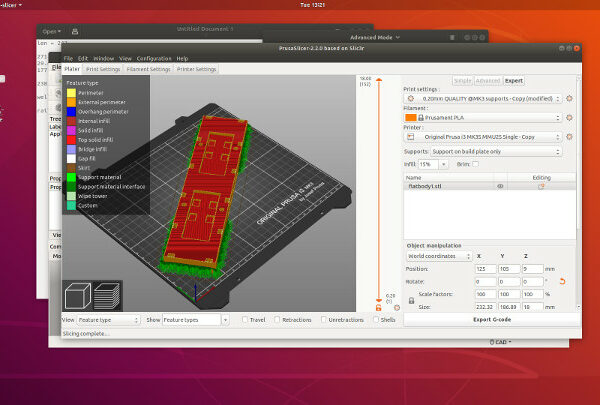

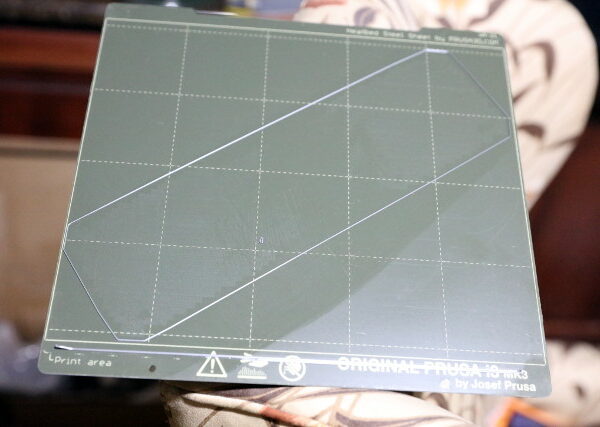

I had one long print in the queue which I figured would be great to test this stuff. It's the main base plate of an O scale model railroad flat car, and it's a model that has to be placed 'cattywumpus' on the plate, since putting it on square results in that dreaded 'tool out of print bounds' error when supports are added. This is a model that NEEDS supports on both ends of the model on the track-facing (not normally visible) side.

The product comes with a sponge applicator in the bottle, with a 'push flow' valve, as in hold the sponge end to the plate and push and the flow starts. The instructions say to apply a 'thin' coat on the plate, which I did in the areas of the print, using the screen cap above as a guide.

The instructions also recommend doing a calibration print after applying, but looking at the dried layer, it was obvious that it was thinner than a coating of glue stick (and far more consistent too) so I figured that if the first layer appeared too squished I could quickly dial the Z up a bit.

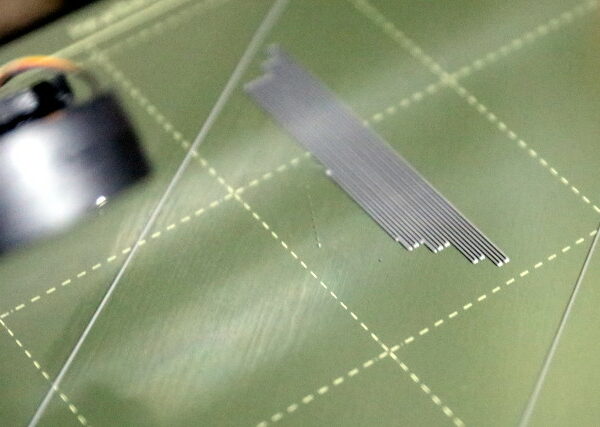

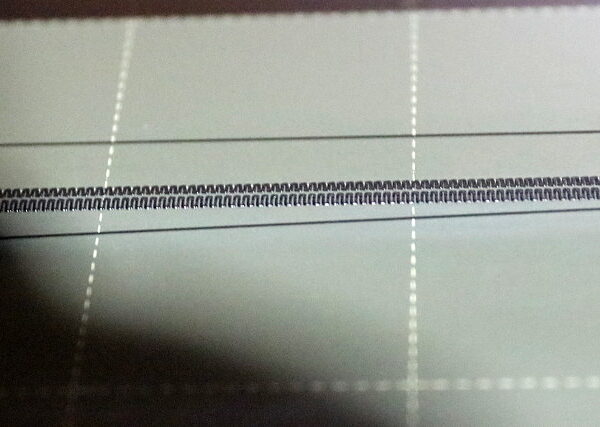

I launched the print and carefully watched as the priming line, skirt, and first layer of support were laid down.

I was very pleasantly surprised, as the support material, even the smallest 'square wave' sections were in perfect contact. Not a single up-turned end or corner. The ends were perfectly square.

For a first impression, I am, indeed, impressed.

It's now about 45 minutes into an eight hour print. I will most likely not see the results until I wake up tomorrow.

Instructions say to let it cool to room temperature and that 'You may hear crackling and popping sounds as your part begins to release from the build plate' and that it should release with minimal effort.

In this shot you can see the edge of the coated area and the properly-adhering support material.

Detail of support material on the first layer.

The one thing I did not notice when I ordered it was that the instructions say that it is intended for glass plates. However, it says that it may be used on top of blue painter tape and other surfaces, but not on bare aluminum plates.

The data sheet says it contains a 'proprietary polymer' and is water soluble. It has virtually no odor, so I sure can't tell what it's made of.

So far, I am satisfied and impressed. Let's see what the finished print looks like, and how it behaves if needed in other circumstances.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

I am glad you agree. I absolutely love this stuff. Layerneer Original Bed Weld 3d Printing Adhesive is easy to use and easy to remove when cool. I added a link to buy it on Amazon. It tends to be more available in the US. If Europeans are interested, Dimafix is of similar quality.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

Thanks for the link.

Here's a quick follow-up following the overnight print.

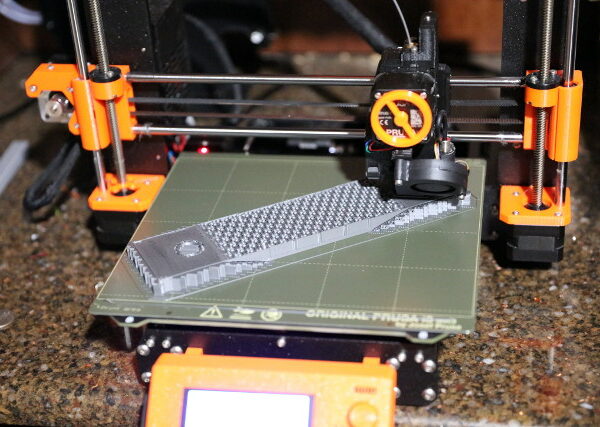

Print in progress. Taken before I retired for the evening, of course. Starting to look like a flatcar, if you use your imagination.

Finished print, just a few minutes ago. Build plate has obviously cooled to room temperature.

Very clean release. It popped off cleanly with just a few flexes of the steel sheet. Only one small support remnant did not release.

Last gasp of the support. 🙂 Of course it came off easily.

You can see the pattern of the support material, which, by the way, pulled off of the model easily with no tools, using the parameters that have been discussed here.

Since the next print in the queue is to be done with black ABS on the textured sheet, which has shown to need no help at all to stick, I cleaned this one off with IPA and set it aside.

Cleaning this product off with IPA has more or less the same look and feel as cleaning off the glue stick with IPA. Diluted residue is obvious in the wet paper towel. Second clean paper towel removed the rest.

They say that this can be left on the bed, but since this was a special application in the footprint of something I will not print again for some time, I cleaned it off.

I continue to have a very good impression of this product.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@jsw

Do you mind if I add some comments from my tests? I did a review of this product on another site. I pretty much agree. I also have some new photos.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@jsw

Do you mind if I add some comments from my tests? I did a review of this product on another site. I pretty much agree. I also have some new photos.

Of course, please do. Additional experience and technique discussion is always appreciated. Ditto with photos.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@jsw

I am 3D printing for about 3 years and I never used a glue stick or something other - only the PEI sheet which is comming originally from Prusa. But when I look at your support structure at first layer it looks like I will give it a try and order something like this. I had issues with adhesion - but using this magic stuff looks like making it much easier.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@clemens-m

Yes. It allows supports to stick to the plate more.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

The most tricky cases seem to be with very small pieces and with supports that use PLA filament. I figure that the more contact area a piece of the print has, the less likely it is to separate from the plate.

Sooner rather than later I expect to try soluble supports, and in anticipating this, I'll most likely use the Bed Weld to be sure. They say that the support material I have but have not yet used (the Verbatim BVOH) behaves very much like PLA, so I figure the Bed Weld is a good thing to use for this.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

I concur with JSW's review, I wrote a review that I never posted:

Layerneer Bed Weld

If you anything like me, you have found that difficult to stick filament that just will not stick no matter what adjustment you make to the Z height or how many times you clean the bed. The best part about the claims of this adhesive is that is reports that you can also remove the prints easily once the bed is cooled. I am fed up with my parts warping and coming off of the build plate or over adhering to the plate when it is cooled. I have tried glue sticks and they do work but they can be a little temperamental if you get them on too thick. Then comes Layerneer Bed Weld to the rescue.

Bed Weld is a 3D printing adhesive that was developed specifically to resolve the technical challenges associated with build plate adhesion during prints, while also hindering easy removal parts once the print is complete. The quite simply is limit failed parts several hours into a marathon print session and long intimate periods with a spatula or razor blade prying off parts that are stills emended to the build plate after it is cooled. The goal is less damaged parts and fewer cuts to your knuckles and hands (see razor blades). The product was designed for applying directly to glass printer beds but as I have found, it works on PEI and Bondtech.

What is Layerneer Bed Weld?

It is listed on the MSDS as a harmless polymer. I am not sure what that actually is or just how harmless it is, but I would not recommend using it with eating or drinking implements.

Application:

The adhesive liquid is applied by a foam applicator on the tip of the bottle and allowed to dry as the bed heats. I would recalibrate the Z height with the addition of the layer of Layerneer.

Who is Layerneer?

Layerneer is based in Palo Alto, California. The product is primarily sold on Amazon and in the United States. They are a Veteran owned company that focuses on a family atmosphere. Their stated mission is “to make products that deliver impressive results, we continue to further develop additional solutions for the 3D printing market”. The company started developing adhesives for 3D printing in 2017. Bed Weld – Original is their first product in a series of adhesives planned and specifically engineered to solve warping and first layer adhesion challenges. At the time of the post, it is their only product on the market.

Can it be used on PEI?

It was designed and recommended for Glass. Many users have used it on Blue tape, Kapton, PEI, and Bontech and have reported success. I am on one of them. Heck, I even added it to a plain steel bed and it worked. FYI, never put a steel bead against the Prusa heat bed. I used blue tape on the underside.

My experiences:

I have used 5-6 other adhesives, 50/50 Elmer’s Glue, and multiple glue sticks. I have used them on both glass and flexible steel beds with multiple sheets and have found them to work. I will post a comparison to Layerneer. The bottom line is that Layerneer is on par with Dimifix and Magigoo (for most filaments) and it is easier to clean.

Rating:

- Ease of use: 5/5

- Clean up: 5/5

- Adhesiveness: 5/5

- Release on cooling: 5/5

- Price: 4/5

I have more to post including my print result. Unfortunately, it is sold out on Amazon. Soon after JSW posted this posy, it went out of stock. Keep checking back for more Layerneer Bed Weld.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

Update from Layerneer:

We cleaned them out. They have more shipping out the Amazon in the next couple of days.

I also told them that it works well with a Prusa Build Plate.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

We cleaned them out.

So, do I get a commission? 🙂

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@jsw

I only wish we both did.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

Layerneer Bed Weld

I have more to post including my print result. Unfortunately, it is sold out on Amazon. Soon after JSW posted this posy, it went out of stock. Keep checking back for more Layerneer Bed Weld.

Amazon has them back in stock!

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

Have you (or anyone) re-used a Bed Weld surface?

The three prints I've used it for have all had supports in specific areas, and that's what I coated and cleaned off after use.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@jsw

Yes, I reuse it. I only clean it between filaments. I have reserved it mostly for difficult to stick prints or filaments. I use it a lot with prints that are heavy in supports.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

I may just coat most of one side of a smooth sheet and use it that way for a while if you've had good luck doing it that way. So far I haven't seen a need to adjust the Z when using it, even though the instructions say to check it.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

@jsw

Me either, but I did do a first layer to confirm.

--------------------

Chuck H

3D Printer Review Blog

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

i think i just became of a believer! i do not like putting anything on my MK3S+ heat bed and all was fine and dandy happy printing. Then comes the XL where i use PETG for supports, still printing fine and dandy happy but pulling out the PETG supports was scary. i was afraid i'd ultimately damage my Satin Sheet so i tried this product. I haven't printed with PETG supports yet because im finishing prints that only need PLA but im confident it'll perform as advertised. i will update as soon as i use PETG again.

RE: Product Review - Layerneer Original Bed Weld 3d Printing Adhesive

If you have a new build plate with that new XL, this makes sense.

It seems like many of the plates get better after use, as far as getting the filament to firmly stick to it.

I've now been using the Layerneer for close to four years, and it REALLY does help, particularly with supports that have small footprints. It works very well as both an adhesion booster and as a release agent.

It's not a substitute for cleaning your build plate (and be sure to clean it MY WAY!) or having your Z calibration spot on, but it can surely help with frustrating adhesion problems.

I use it on the PEI and textured plates on the Prusa and glass plates on the Ultimaker, and it work very well for all of those.