Problem with the seccond layer

Hello,

I have a problem with the MK3S+ with MMU2S.

I start a print and the printer starts printing normally. The first layer is beautiful! But the second layer, the layers get really stupid! I then played around with the temperature (200°C - 250°C) and the speed (even slower than the first layer). That worked for one print, but now I can't do it at all.

As a further step I did a cold pull (cleaning the nozzle), looks clean! I cleaned all the wheels on the shaft with which the filament is pushed and checked whether they are firmly on the shaft, which is also the case. Then I checked whether all stepper motors that have something to do with the filament are all running smoothly and are not getting unusually hot.

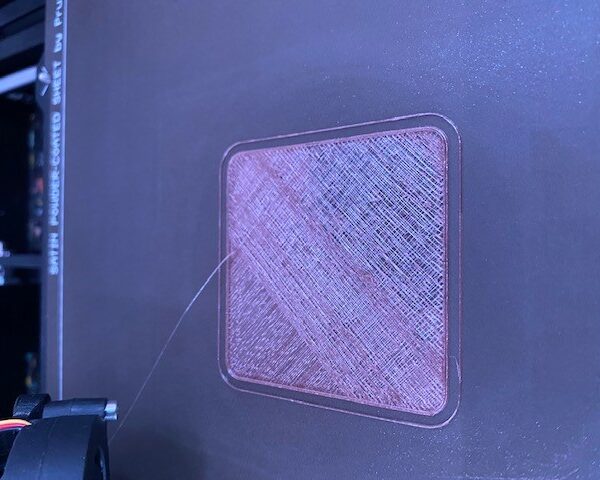

I don't know what else I can do. I've tried everything I found on the internet and now I'm desperate. I've attached a few pictures.

Does anyone have an idea?

white filament has broken off in the second layer

Brown filament has broken off in the third layer.

RE: Problem with the seccond layer

You look to have a partial jam. Do a cold pull? Did you recently change filaments?

--------------------

Chuck H

3D Printer Review Blog

RE: Problem with the seccond layer

Might be a partial clog or too much resistance in MMU/filament path. To the tell the one from the other: try printing without the MMU, if the problems persists your extruder is the problem (feeding/gears, PTFE tube damage, partial clog) if it prints well without MMU, check the resistance of the filament path.

To print without MMU without much of unplugging: Switch off spool join and filament sensor in LCD menu, remove PTFE between MMU and extruder. Print something sliced in MMU single mode and when the MMU feeds filament into the air just insert some other filament form a different source into the extruder manually.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Problem with the seccond layer

As posted before: find out if it‘s the extruder or the MMU2/filament path that causes the underextrusion. Then continue accordingly.

I used to have the same problems when I first started using my MMU, in my case ID 2.5 and ID 3 PTFEs, the pass through adaptor and some tweaking of the filament buffer solved the issue.

If you experience this kind of continuous underextrusion with default slicer settings you either have a problem within your extruder or the friction in your filament path is to high for the extruder to pull the filament. Find out what it is first, by taking the MMU, feeding tubes, buffer and/or auto rewinding spools out of the equation.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!