Print Quality problem

Hi,

I have printed 2 lead screws, one in PLA and one in PETG(both Prusa filaments). As you can see in the pictures the top of the screw just doesn't print very well, the rest of the part is perfect until it gets to the top which is just supposed to look like a smooth round shaft.

I have just used all the standard settings inside Prusa slicer 2.1 for the Prusament PETG(red screw) and PLA(green screw), I'm very new to this and don't know where to look to clear it up and any help is appreciated.

I'm using a MK2.5 with the latest firmware.

RE: Print Quality problem

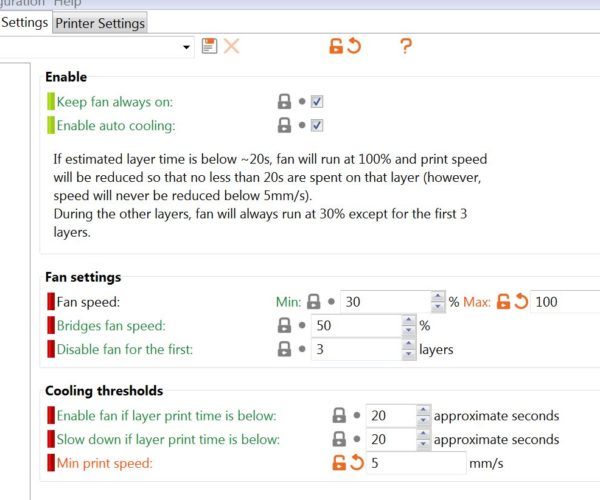

Best guess is cooling time between layers needs to increase for the last small diameter section. Add time, and/or add some print fan speed.

RE: Print Quality problem

A simple way to increase cooling time for small layers like the above is to add another instance of the object you are printing. Usually when I do that I space the two objects far enough apart that the extruder assembly will only be above one object at a time. Then when the print finishes you have a spare part! 😉

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: Print Quality problem

Best guess is cooling time between layers needs to increase for the last small diameter section. Add time, and/or add some print fan speed.

Thanks for the thoughts, I will try to figure out how to do that.

RE: Print Quality problem

A simple way to increase cooling time for small layers like the above is to add another instance of the object you are printing. Usually when I do that I space the two objects far enough apart that the extruder assembly will only be above one object at a time. Then when the print finishes you have a spare part! 😉

Thanks for the idea, I worry about wasting filament but when it only cost a dollar to print one I guess it doesn't matter. lol

RE: Print Quality problem

A picture of the part on the build plate as it is being printed would be helpful.

Printed vertical? Did you use a brim? Was there any noticeable wobble when it reached the top section? How much infill? Wall thickness?

How tall is the part?

What you show - is very unusual. Prusa does round columns very well.

RE: Print Quality problem

If you are worried about wasting filament and want to see results fadter, move model under the plate in slicer, so that only part you are interested about is on print area. This way you can print only small part of lead screw to verify if your settings are OK. You can also stop before it finishes if you see it not being good.

RE: Print Quality problem

FYI: you can't easily "move a part under the plate" but you can CUT the part near the top to remove excess material that would have printed before the area of concern. Simply select the CUT tool and drag it to where you want to cut the part. You don't need to keep the lower section after the cut, so clear that check box before cutting.

RE: Print Quality problem

A picture of the part on the build plate as it is being printed would be helpful.

Printed vertical? Did you use a brim? Was there any noticeable wobble when it reached the top section? How much infill? Wall thickness?

How tall is the part?

What you show - is very unusual. Prusa does round columns very well.

I printed it vertical with the poor quality part happening at the top, it did not wobble when I was watching it. I printed the part at 20% infill with no brim but supports from build plate only. The largest diameter is 15mm and the diameter where it failed is 9.5mm and I used the preset preference std. of 2mm perimeter thickness( not sure if that is wall thickness though). Overall height is about 160mm.

RE: Print Quality problem

If you are worried about wasting filament and want to see results fadter, move model under the plate in slicer, so that only part you are interested about is on print area. This way you can print only small part of lead screw to verify if your settings are OK. You can also stop before it finishes if you see it not being good.

Not too worried about the filament but I never thought about chopping it down to see if that particular area had a problem. I will keep that in mind.

RE: Print Quality problem

FYI: you can't easily "move a part under the plate" but you can CUT the part near the top to remove excess material that would have printed before the area of concern. Simply select the CUT tool and drag it to where you want to cut the part. You don't need to keep the lower section after the cut, so clear that check box before cutting.

Thanks, I will try that. I thought maybe it had more to do with the height of the part than the actual section where it goes bad but maybe I need to rethink that.

RE: Print Quality problem

I still think it is wobble.... That is one tall, skinny part.

Cut your speed down to 50% in the top section. It won't add that much time. And make sure your brim is holding...

Or maybe post your STL file.

RE: Print Quality problem

The top end of the gearing looks good enough I doubt wobble is 100% of the problem. Might be, but my bet is a heat related problem, and why PETG looks much worse than the lower temp PLA.