Print quality after replacing nossle

Hi everyone. Looking for some help. I have an Mk2 and couldn't be happier with it. It has performed flawlessly for 2 years. I recently changed out the nozzle (I purchased spares when I purchased the printer, so i expect they're the same). The process of replacing the nozzle went pretty flawlessly. We followed the directions, which were pretty detailed. We ran it though the 1st layer calibration several times to the z adjustment just right.

After we got it put back together and made our first print though, we noticed an issue. The PLA that has been printing so flawlessly, isn't printing so flawlessly anymore. It is just not laying down like it used to and there are a bunch of striations.

Not sure if this is related or not, but when I look at the LCD as the items are printing, the temp reading fluctuates significantly - from 170s to the 215 print temp that it should be. Obviously, if the print temp isn't significantly over 170, the filament won't melt. Not sure that is it though because it seems like it is laying down fine, then it isn't. I don't think the nozzle could cool down that quickly.

We use our printing mostly for a high school rocket club. Many of the parts are subject to high stress with many gs (i.e. rocket fins, tail cones, etc.). So it's important that we get really good layer adhesion. Not sure if my issue is that I need to do more calibration, or if it is a sensing issue.

Really appreciate the forum's help in this.

RE: Print quality after replacing nossle

Did you do a PID tune after the nozzle swap?

RE: Print quality after replacing nossle

@bobstro

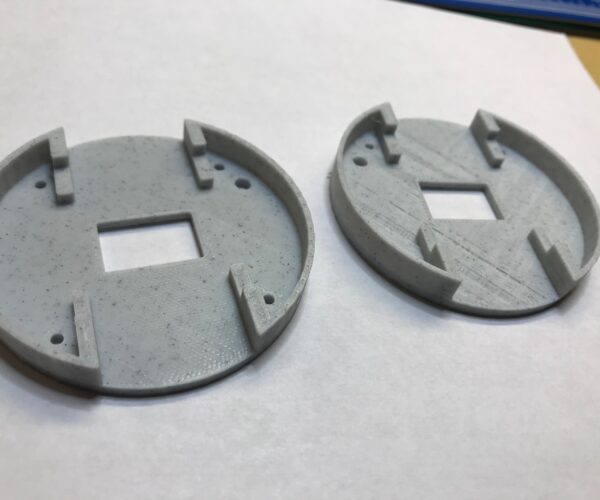

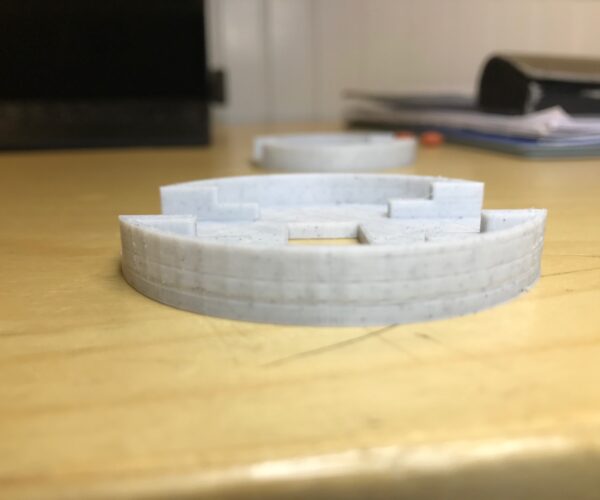

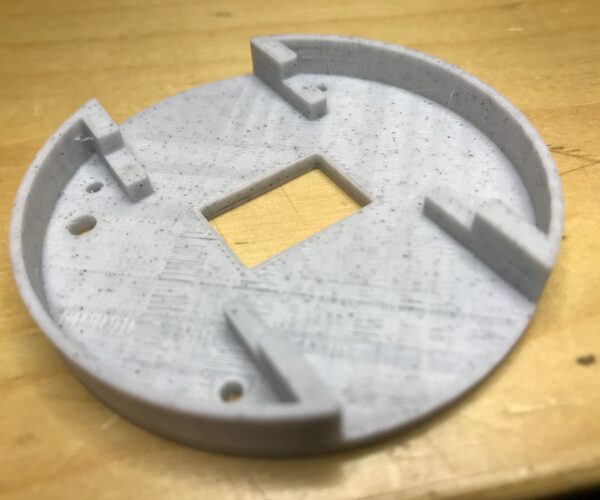

Thank you thank you. I didn't know what a PID was, but now I am so glad that I do. Making that small change made all of the difference in the world. MK2 is better than ever. I have the two printed parts side by side. the only difference made was calling out the specific PID values in the G-code. What a difference. Thanks again.

RE: Print quality after replacing nossle

Someone braver than me try that link.

That post is devoid of content, and all my Spidey Spam Sensors are tingling...

RE: Print quality after replacing nossle

Someone braver than me try that link.

That post is devoid of content, and all my Spidey Spam Sensors are tingling...

Better not, it'll probably try to steal your spotify credentials with a clone app to bait people looking for free account upgrades. 😛

RE: Print quality after replacing nossle

Post deleted

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: Print quality after replacing nossle

I was wondering what was going on there, the penny has dropped, I take it the bogus links are no longer just some sort of diplomas, but something more sinister 😀

Back to the original post, I'm impressed by how much difference a PID tune can make, I would never have thought the difference would be this much, and that marble filament looks really good.

Every day's a school day 😀

Normal people believe that if it ain’t broke, don’t fix it. Engineers believe that if it ain’t broke, it doesn’t have enough features yet.