Re: PLA Curling after Part Update

And again it´s time for some magic. 😉

Try dish washing liquid and hot water.

IPA does not remove all residues from the steel sheet.

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: PLA Curling after Part Update

Just to be clear, its the bed temp raising that had the desired effect - I've been using IPA since I got the mk3 and still had issues.

Hope this helps,

Texy

Congrats on making progress! I have not raised the bed temp that high - I will try and report back. When I have "stick" issues, I often wipe with a little acetone instead of 99% IPA and that tends to help a lot.

Re: PLA Curling after Part Update

Just to be clear, its the bed temp raising that had the desired effect - I've been using IPA since I got the mk3 and still had issues.

Hope this helps,

Texy

If you have a little time, can you try printing the robot .stl I posted? It's a fairly quick print (and even quicker if it fails). Really interested to see if you have the same problems.

Re: PLA Curling after Part Update

Just to be clear, its the bed temp raising that had the desired effect - I've been using IPA since I got the mk3 and still had issues.

Hope this helps,

Texy

If you have a little time, can you try printing the robot .stl I posted? It's a fairly quick print (and even quicker if it fails). Really interested to see if you have the same problems.

Sure, but specifically which model? And what was the orientation you tried?

Texy

Re: PLA Curling after Part Update

Just to be clear, its the bed temp raising that had the desired effect - I've been using IPA since I got the mk3 and still had issues.

Hope this helps,

Texy

If you have a little time, can you try printing the robot .stl I posted? It's a fairly quick print (and even quicker if it fails). Really interested to see if you have the same problems.

Sure, but specifically which model? And what was the orientation you tried?

Texy

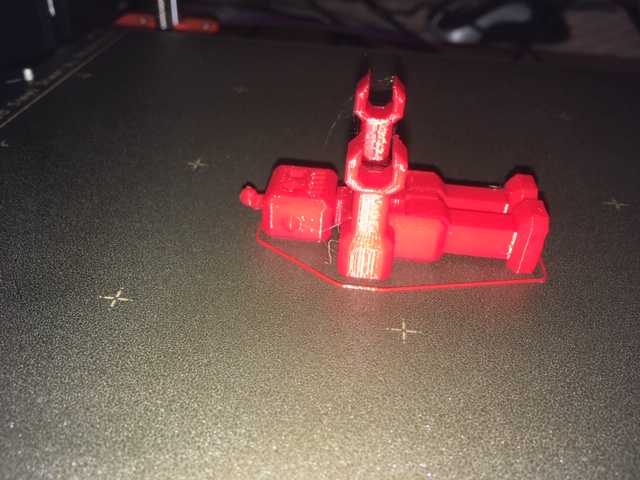

I am using this as a test model: https://www.thingiverse.com/thing:1695590

Printing right now with bed raised to 70c and it started to curl, but not as significantly as before. It looks like the print will finish successfully.

Previously, I tried it in multiple orientations and they all failed.

Re: PLA Curling after Part Update

The download had multiple models. Which one are you printing?

Re: PLA Curling after Part Update

Tried many more times to finish a second one of these prints and I can't get the printer to finish without the "clicking" extruder sound my printer does far too often.

Re: PLA Curling after Part Update

The download had multiple models. Which one are you printing?

robotV8BHiveLabs

Re: PLA Curling after Part Update

OK, thank you very much. Was there any curling for the first 5-6 mm?

This machine has been nothing but trouble for me since it arrived. Prusa is sending me a new extruder motor, so hopefully that will help.

Re: PLA Curling after Part Update

No curling at all, although its not the best model to see that. Why are prusa sending you a new extruder motor?

Re: PLA Curling after Part Update

No curling at all, although its not the best model to see that. Why are prusa sending you a new extruder motor?

It starts clicking after many rebuilds / completely new hotends / all the typical troubleshooting steps for this problem.

Re: PLA Curling after Part Update

No curling at all, although its not the best model to see that. Why are prusa sending you a new extruder motor?

For me, the curling was very obvious and I did have lots of failures because of it. So if you are saying it would be difficult to see, there is something clearly wrong with my printer.

Re: PLA Curling after Part Update

Another photo of the curling problem which just ruined this print today. Little curl on the edges that the nozzle then hits and knocks the parts off the bed.

IMG_0505.jpg

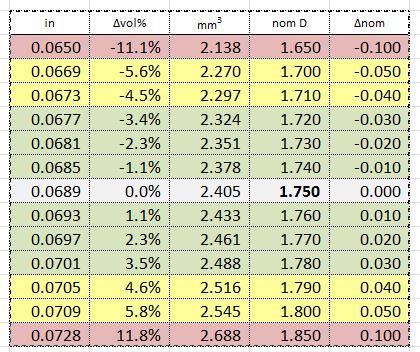

I decided to redo my extrusion multiplier for this material using the cube method / measuring the walls, etc and the curling almost gone! I guess I was waaay over extruding, as my new multiplier is down to .87. from .98.

Re: PLA Curling after Part Update

Another photo of the curling problem which just ruined this print today. Little curl on the edges that the nozzle then hits and knocks the parts off the bed.

IMG_0505.jpg

I decided to redo my extrusion multiplier for this material using the cube method / measuring the walls, etc and the curling almost gone! I guess I was waaay over extruding, as my new multiplier is down to .87. from .98.

Actually extruder multiplier calculations isn't something I've toyed with much - so what size did you cube end up, to get those figures?

Texy.

Re: PLA Curling after Part Update

Another photo of the curling problem which just ruined this print today. Little curl on the edges that the nozzle then hits and knocks the parts off the bed.

IMG_0505.jpg

I decided to redo my extrusion multiplier for this material using the cube method / measuring the walls, etc and the curling almost gone! I guess I was waaay over extruding, as my new multiplier is down to .87. from .98.

Actually extruder multiplier calculations isn't something I've toyed with much - so what size did you cube end up, to get those figures?

Texy.

I just tried to attach the .stl but it wouldn't let me. It's a 20mmx20mmx10mm cube I drew in Fusion. When you go to print, set it up for vase mode and 0 top and 0 bottom layer with 1 perimeter. Also, set your extrusion mulitplier to 1 and your extrusion width equal to the nozzle. When it finishes, measure 2-3 times per side and take the average wall thickness. Your new multiplier = old multiplier x (extrusion width / average measurement). Repeat until you are satisfied with the wall thickness.

In addition, I also ran the built in temp cal and PID calibration.

Re: PLA Curling after Part Update

Wrong thread ...

Re: PLA Curling after Part Update

Thanks - I'll give that a go. If you rename the stl file as a txt file you'll be able to attach it.

regards,

Texy

Re: PLA Curling after Part Update

I'd had this effect on parts with extreme overhang angles and unsupported perimeters.

Doesn't the extruder flow depend a lot on the filament diameter, that any variation in filament diameter changes what is laid down by the extruder?

At least I've seen some examples where the filament seems to have been much thinner and much thicker resulting in over-extruded layers followed by under-extruded layers. It's enough of an issue I will measure filament during prints and found that diameter will change randomly in some big ways - enough that a single adjustment can't compensate all cases.

Anyway - a simple measurement of the filament diameter about a meter in and then a few spool layers in gives me a good idea what to expect.