Physical strength PLA vs PETG

Hey guys,

I'm currently designing and printing some connectors for square tubing for one of my projects. I printed a first draft out of PLA I had laying around and since all dimensions and multiple websites vlaimed PETG would have better physical properties I ordered some Prusament PETG.

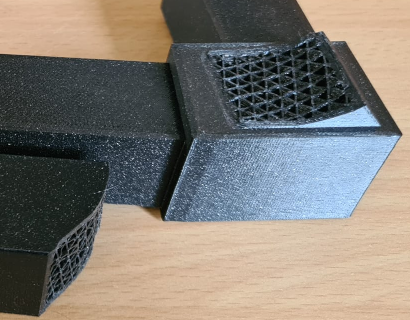

Here you can see the results. On the left there is the test print with PLA and on the right is the PETG print.

I wanted to test the strengh of the part and tried to bend/break it like I did with the PLA part and it more or less broke instantly. Since the connectors are a crucial element for the structural integrity of the project they should be strong.

Am i doing something wrong with the slicing settings or with tempreature or anything like that, or is it actually a material based problem ?

Really looking forward for some help/advise.

To get best strength from a part the printing orientation is important. Extrusion partially aligns the polymer molecules and the part is much stronger in one plane than another - careful print alignment can take advantage of this. Interlayer strength is often affected by print temperature but this is usually a lesser effect.

Most of the strength is in the perimeters, more perimeters increase strength noticeably.

PETG is not *stronger* than PLA in most senses but it's mode of failure is different. PLA is brittle and will not survive shock/vibration, it shatters. PETG is tougher, survives more shock and vibration but deforms as it fails. Nylon is like PETG but more so.

Cheerio,

RE: Physical strength PLA vs PETG

Do I understand it correctly that the PETG part is the one that snapped as shown in the picture?

I don't see it very clearly but it seems as if the breakage was to a large extend roughly along layer lines, is that correct? If so, you have an issue with layer adhesion. PETG should actually usually show pretty good layer adhesion. Settings improving layer adhesion are increasing nozzle temperature and reducing part fan speed (or possibly turning it off). Of course, both factors can also worsen print quality if too extreme (and especially reduce overhang printing capabilities). There is usually some wiggle room however for the settings.

Not every PETG is the same though. For example the Extrudr PETG is rather untypical and more rigid but also breaks easier. Prusament PETG on the other side should be behave more like one would expect from PETG.

Regarding general material features:

- PLA is a lot "harder" than PETG, or PETG is more flexible, if you look at it from the other side. So one would expect that PLA is more brittle than PETG (different side of the same coin), which is why your example is a bit curious.

- On a first sight PLA might often look more robust but a key downside is its tendency to creep, even though it is so hard. That means it will slowly bend when confronted with a force over a long time. PETG does that considerably less so.

- Another downside is that PLA's heat stability is so low that part deformation can already set in at intense sunshine and especially for example on a summer day in inside a car. PETG is not a super heat stable material but can take a bit more.

- PLA also has a tendency of getting more brittle over time, as it slowly hydrolizes due to air humidity. PETG does that much less so or hardly at all.

For heavy duty applications I have become a fan of Prusament PC-Blend (out of stock currently). It is incredibly tough, has great interlayer adhesion, the opposite of brittle yet "harder" than PETG. It is however difficult to print and only suitable for compact pieces as warping is a major issue. It is also much more expensive than other filaments and recommended for people with some experience.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE:

I am relatively new to 3Dprinting and have seen similar breaks for some of my parts.

I resolved that by printing the (not that big) part with 100% infill.

Your image looks like that would help your print as well, for PLA and PETG:

I read that it is possible to make PrusaSlicer do print with 100% infill at specific area(s) only, but don't know how.

100% infill is almost always a mistake. It's rare to need more than 25-30%, instead increase the perimeters. Voids in the fill act as crack-stoppers and mitigate the more dramatic failures.

...but if you choose to ignore this advice use modifiers.

Cheerio,

RE: Physical strength PLA vs PETG

^^ Indeed. Standard Voron print settings for example are 40% infill with 5 perimeters and that is rather on the high, robust side of printing. If that is not enough, rather increase perimeters than infill. Or work with localized modifiers.

Mk3s MMU2s, Voron 0.1, Voron 2.4