PETG Speed vs Quality and beyond

I've recently got my machine (a stock Tevo Nereus) tuned in quite good with a generic petg.

Quality aside, i've got in my opinion great results with petg.

This filament, Clas Ohlson universal PETG, i run at 235 with 65c bed.

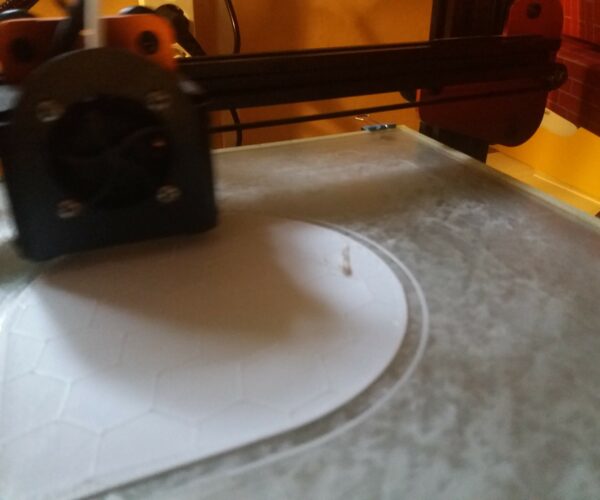

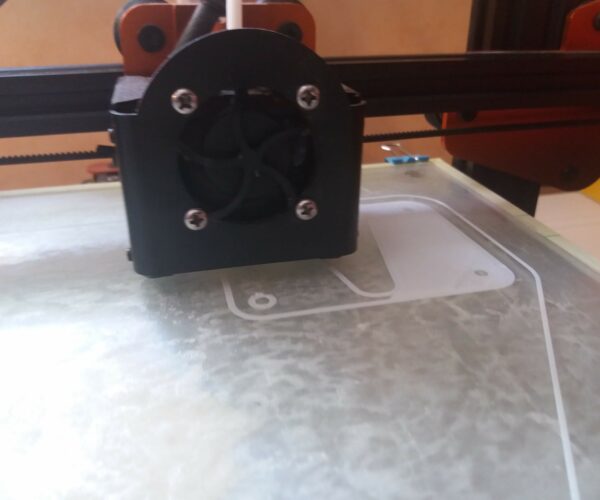

4mm window glass on stock alu heated bed. Lots of gluestick and i really jam the first layer in there.

According to PS on 0.4nozzle with 0.6 wide extrusion and 60mm/s i'm running around 9ish volumetric thruput.

A 0.6nozzle with 0.6 wide at 60mm/s show around the same 9ish vol met thruput.

A 0.6nozzle with 0.8 wide at 60mm/s get capped at 12mm/2.

I dont think i should push the speed higher with the large glassbed.

I have considered a 0.5 or 0.6 nozzle, but then i think i would loose out on the smaller objects i sometimes do?

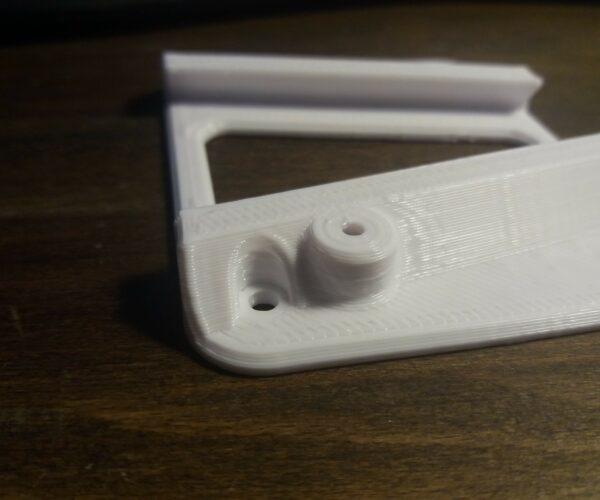

Like the clips below, the curved arch is 2mm wide.

As far as i can tell, i don't have any over or underextrusions (most of the time anyways).

The little blobs are when the nozzle sheds whenever it accumulates.

Any thoughs or other inputs i'd appreciate it.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: PETG Speed vs Quality and beyond

A bigger nozzle will let you push a lot more filament at slower speeds, so is good for your concerns about the weight of the bed. For functional parts, 0.6mm is a good middle ground. Obviously, big printers aren't idea for printing miniatures.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PETG Speed vs Quality and beyond

Yeah it's kinda where my thought are leaning.

It's a standard mk8 hotend on these ones, and a closer inspection of the heaterblock it begs me to get a siliconesock as well.

This is the only machine i have set up for petg, i don't quite trust my flsun QQs with petg, and i rarely do so small clips, this is for a ropeligt where the originals i printed in PLA now start to break at the screwhole.

Thanks for your input.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3