Need Feedback from i3 mk3 or i3mk3s users

Hello everyone!

I'm considering purchasing an i3 mk3s Prusa printer.

I'm curious if any of you own either the i3m k3s or the i3 mk3 and if so how do you like these printers overall?

How's the print quality especially using the 0.4 mm nozzle? Has anybody used the 0.25 nozzle and if so how was the comparable quality

to the 0.4 mm nozzle?

Does anyone use PETG , on a regular basis, and if so how do you like the prints using this filament?

This would be my first 3d printer. How difficult is it to assemble as a kit? I have good mechanical skills and an understanding

of electronics.

Thanks, in advance for any and all responses!

Gary 😀

Re: Need Feedback from i3 mk3 or i3mk3s users

Kit is an easy build if 1) you know what torque is 2) you can actually follow instructions 3) have some patience for those times when something just doesn't look right the third time you assembled it 4) are thorough and 5) have a couple days: it shouldn't be a race.

I'm thinking the Mk3S is all that is available these days: so that is your option. And the Mk3 laser-based filament sensor has a list of issues long enough you don't really want one: a case of a really great idea with too many implementation issues to overcome.

I've read quite a few ramblings of people complaining their CR10 is XYZ better than the MK3 ... but then why did they buy a MK3 if the CR is that much better? The flip side is many of my professional associates who do 3D printing as part of their jobs recommended the MK3 to me. I spent the $750 for the kit and haven't looked back. I've spent a lot more than that on plastic. And I have purchased the MK3S upgrade parts; and the latest 40w nozzle kit. Still waiting for a good time to bring the printer down for the upgrade. Bottom line: the next best printer that comes close to comparing to the MK3 is a $2,800 beast: and that extra $2,000 buys a few more cubic inches of print volume, that is also enclosed. But there are enclosure plans for the MK3 out there; but so far I have never needed one. Though I print mostly PLA and some PETG; nothing smelly.

Re: Need Feedback from i3 mk3 or i3mk3s users

Kit is pretty easy to build. Excellent instructions are available online.

PETG is also fairly easy to print. Not quite as aesthetically pleasing (ie quality not quite as good) as PLA, but then it generally doesn't need to be. But you aren't limited to just PETG or PLA. You can print many other materials using this printer.

Overall it is a very good printer at a modest price.

Re: Need Feedback from i3 mk3 or i3mk3s users

The MK3 is my first printer and I got it in mid Dec (so 4 months in a few days).

I bought mine pre-assembled rather than the kit since it was my first printer so that if I had troubles I could be confident it wasn't the assembly. As it turns out, the belts were outside their own specs and the Live Z wasn't adjusted as well as it could have been. Still I got a number of good enough prints out of it until I learned about those things.

If you get your Live Z (find the "life z adjust my way" thread) the quality from the 0.4 nozzle is pretty good (having no experience to compare against ;)) when you run a 0.05 layer height*. Even at 0.1 and 0.15 the detail is pretty good.

I do have a 0.25 nozzle (as well as a 0.6). I ran it once while I was printing lots of Benchies to compare layer heights and nozzle widths. This was before I got my Live Z dialed in. What I found was that there was a noticeable difference, but not enough over the 0.4 for most things. Similarly the 0.6 didn't increase the speed enough to make it worthwhile for most things. I should do another test with the Live Z dialed in as that made quite a significant difference in the 0.4 results.

Overall it has been a great for a first printer and I've had no real problems with it since I learned how to clean the PEI sheet properly. I've been fighting with a jam issue the last week though. I've been printing 0.05 prints for the last month non-stop. With the last two jobs it's been clogging up on me. Apparently the bore of the Prusa heatbreak is not straight through like most (all?) others and this is attributed as a likely cause for clog issues on prints with lots of retractions. The heatbreak is like this to support the MMU so if you aren't using the MMU you can change that out and that reportedly solves most clogging issues.

This clogging issue is really irritating, but I'm still happy with the printer and glad I selected it over the much more expensive option that I was considering.

Re: Need Feedback from i3 mk3 or i3mk3s users

Kit is an easy build if 1) you know what torque is 2) you can actually follow instructions 3) have some patience for those times when something just doesn't look right the third time you assembled it 4) are thorough and 5) have a couple days: it shouldn't be a race.

I'm thinking the Mk3S is all that is available these days: so that is your option. And the Mk3 laser-based filament sensor has a list of issues long enough you don't really want one: a case of a really great idea with too many implementation issues to overcome.

I've read quite a few ramblings of people complaining their CR10 is XYZ better than the MK3 ... but then why did they buy a MK3 if the CR is that much better? The flip side is many of my professional associates who do 3D printing as part of their jobs recommended the MK3 to me. I spent the $750 for the kit and haven't looked back. I've spent a lot more than that on plastic. And I have purchased the MK3S upgrade parts; and the latest 40w nozzle kit. Still waiting for a good time to bring the printer down for the upgrade. Bottom line: the next best printer that comes close to comparing to the MK3 is a $2,800 beast: and that extra $2,000 buys a few more cubic inches of print volume, that is also enclosed. But there are enclosure plans for the MK3 out there; but so far I have never needed one. Though I print mostly PLA and some PETG; nothing smelly.

Thanks Tim! Your info is very helpful. I don't think I'll have any problems assembling the kit. Yes, I do know what "torque" means. I can follow instructions and I'm patient. $2,800 is a big jump from $800 (including shipping) ! I think the Prusa is a good place to start especially with all the available support.

Re: Need Feedback from i3 mk3 or i3mk3s users

Kit is pretty easy to build. Excellent instructions are available online.

PETG is also fairly easy to print. Not quite as aesthetically pleasing (ie quality not quite as good) as PLA, but then it generally doesn't need to be. But you aren't limited to just PETG or PLA. You can print many other materials using this printer.

Overall it is a very good printer at a modest price.

Thanks Rob for the info on PETG and PLA. I might try some ABS later when I build an enclosure. Does the heated bed that comes with the kit get hot enough to print ABS?

Re: Need Feedback from i3 mk3 or i3mk3s users

The MK3 is my first printer and I got it in mid Dec (so 4 months in a few days).

I bought mine pre-assembled rather than the kit since it was my first printer so that if I had troubles I could be confident it wasn't the assembly. As it turns out, the belts were outside their own specs and the Live Z wasn't adjusted as well as it could have been. Still I got a number of good enough prints out of it until I learned about those things.

If you get your Live Z (find the "life z adjust my way" thread) the quality from the 0.4 nozzle is pretty good (having no experience to compare against ;)) when you run a 0.05 layer height*. Even at 0.1 and 0.15 the detail is pretty good.

I do have a 0.25 nozzle (as well as a 0.6). I ran it once while I was printing lots of Benchies to compare layer heights and nozzle widths. This was before I got my Live Z dialed in. What I found was that there was a noticeable difference, but not enough over the 0.4 for most things. Similarly the 0.6 didn't increase the speed enough to make it worthwhile for most things. I should do another test with the Live Z dialed in as that made quite a significant difference in the 0.4 results.

Overall it has been a great for a first printer and I've had no real problems with it since I learned how to clean the PEI sheet properly. I've been fighting with a jam issue the last week though. I've been printing 0.05 prints for the last month non-stop. With the last two jobs it's been clogging up on me. Apparently the bore of the Prusa heatbreak is not straight through like most (all?) others and this is attributed as a likely cause for clog issues on prints with lots of retractions. The heatbreak is like this to support the MMU so if you aren't using the MMU you can change that out and that reportedly solves most clogging issues.

This clogging issue is really irritating, but I'm still happy with the printer and glad I selected it over the much more expensive option that I was considering.

gnat, I probably won't use MMU. I think you have to change the nozzle to one that is 2.0mm straight through? I was watching a recent video , by the 3d Printer Nerd, and he was discussing the clogging problem and how to fix it.

Well, I'll probably be running the 0.4 mm nozzle and won't worry about the smaller and larger nozzles. I might try them later on but it will be better to uncomplicate my printing by reducing the number of variables in the overall process!

Re: Need Feedback from i3 mk3 or i3mk3s users

gnat, I probably won't use MMU. I think you have to change the nozzle to one that is 2.0mm straight through? I was watching a recent video , by the 3d Printer Nerd, and he was discussing the clogging problem and how to fix it.

Well, I'll probably be running the 0.4 mm nozzle and won't worry about the smaller and larger nozzles. I might try them later on but it will be better to uncomplicate my printing by reducing the number of variables in the overall process!

Sounds like you saw the same video I did. Yes the normal heatbreak is 2mm while the Prusa starts off at 2.2mm.

I think keeping it uncomplicated is the best approach until you've used it awhile. I ordered the MMU at the same time as my printer, but I'm still waiting on it. I've learned so much since ordering it that I'm not sure it's a good idea in my case as it just doesn't sound ready for the inexperienced or people that just want it to work. I really want to work with MM, but other than multiple extruders it seems like the arena has a long way to go yet.

Re: Need Feedback from i3 mk3 or i3mk3s users

Kit is pretty easy to build. Excellent instructions are available online.

PETG is also fairly easy to print. Not quite as aesthetically pleasing (ie quality not quite as good) as PLA, but then it generally doesn't need to be. But you aren't limited to just PETG or PLA. You can print many other materials using this printer.

Overall it is a very good printer at a modest price.

Thanks Rob for the info on PETG and PLA. I might try some ABS later when I build an enclosure. Does the heated bed that comes with the kit get hot enough to print ABS?

The bed gets hot enough to print Polycarbonate or Carbon Fibre, so yes, it does. 🙂

As an example, see here where I printed out an R3 extruder in PC. Although this was printed on a Mk2s the same rules apply for a Mk3.

https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/r3-extruder-printed-in-polycarbonate-t27077.html

Re: Need Feedback from i3 mk3 or i3mk3s users

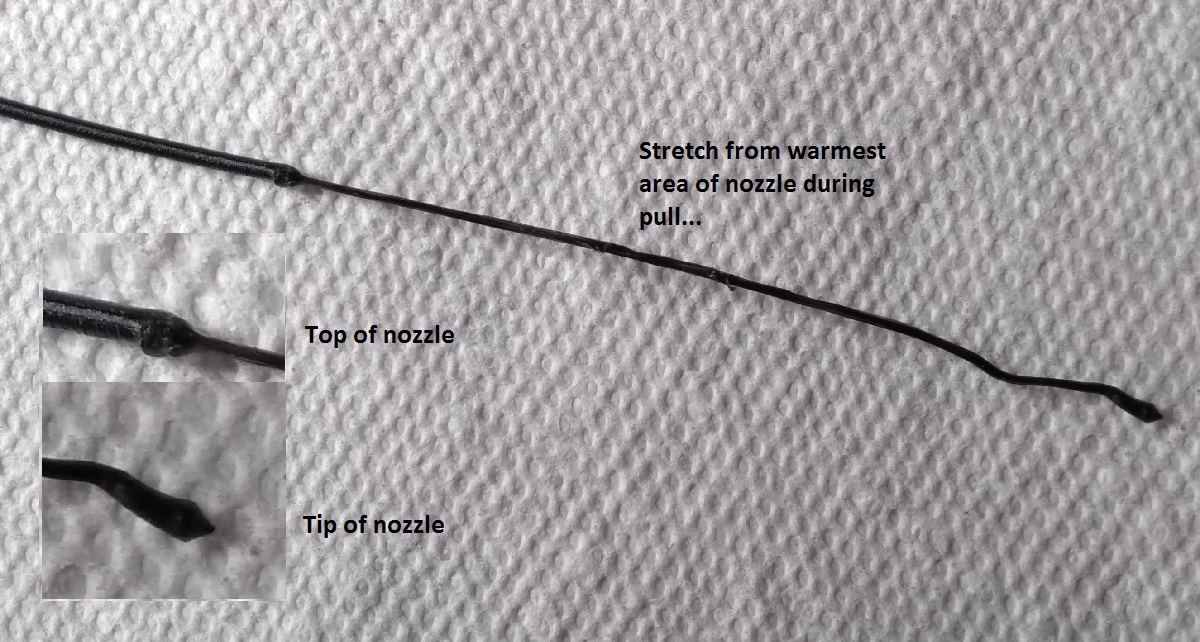

Regarding the heat break claims ... while possible, no one has shown a photo of a three step filament pull. Until that happens I don't really buy into the heat break jam being bantied around. I did have a string of jams that weren't heat related. They were duration related. But in my case filament debris had settled down the heat break and after a period of printing would jam - sometimes just skipping a bit, and sometimes solid jams. Removing the nozzle and blasting compressed air up the heatbreak resolved those jams (I got a geyser-like dust cloud from it).

The E3D-V6 nozzle has a 2mm diameter feed. The E3d-V6 standard heat break is 2mm up to the PTFE bore. When doing a cold pull, you will see a 2mm end that tapers to a cone, followed by 1.75mm filament (or a short stretched section if you are slow on the cold pull).

If you have the "modified" heat break, the theory states hot plastic has been pushed up into the heat break where it expands, cools, then can't be pushed back into the nozzle. Thus, there should be a 2.2mm section in the cold pull, well up into the heatbreak. So far, no one has produced and posted a photo. Then again, maybe my cloud of dust is proof I'm affected - the dust has to settle on something ... lol.

Re: Need Feedback from i3 mk3 or i3mk3s users

I fully agree with Tim above on the kit being easy to build and the instructions being excellent. Two side notes: check also the comments in the online instructions. Those can warn you on possible problems and challenges to face. Second, some stages of the build are more woodworking-ish than electronics-ish (I haven't that much experience on mechanics, so I relate to woodworking and furniture mounting). Namely, setting frame parts to be at a perfect 90° angle —a metal ruler and a pen-sized bubble lever may come in handy at some points.

FWIW, the MK3 is my second printer (the first one is a Delta kit). I fully recommend it. It's an excellent value for the price, and allows a lot of tinkering, and the kit building will help you gain confidence and get familiar with the machine. I haven't installed the MK3S update, though.

As for the nozzle, I have a 0.25 but still haven't tried it. I have tried the Nozzle-X and I'm extremely happy with it. While it's aimed to printing abrasive materials (carbon-filled, glow-in-the-dark...) and high-temp (more than a stock Prusa can handle), I've found some minor improvement in top layers and nozzle buildup cleaning. Being steel, it may require bumping up the print temp a bit, which I've not needed —but I use a copper block, titanium heatbreak and average speeds; I value consistency over time, and that I did even with the stock brass nozzle. Some speeds are beyond E3D V6's capabilities, and yes you can print very fast, but the loss of consistency in infill is obvious to me. YMMV, and changing nozzles and printing specialties comes after you build your kit and are familiar with it 😉

As for PETG, is my material of choice. I love it. I'd say that, sometimes, it can get better aesthetically than PLA. First is filament quality: a good PETG may look better than an average PLA. With some not-that-good-after-all PLA I've found obvious protruding layer lines (due to irregular filament diameter) that do not appear in good PETG, even in some average PETG with the right print settings (PETG allows more Slic3r tinkering, indeed maybe it requires it, but you may get very good results). And then there's the translucent filaments: PETG can get to be more transparent than PLA, and a gyroid-infilled model in translucent PETG is mesmerizing to watch. But, again, PETG is not that good with bridging, has more stringing, etc. And for mechanical parts, good PETG beats good PLA —for a long shot.

Also, if we're talking about PETG, maybe we should bear in mind all the huge range of copolyesters (CPE), closely related to PETG. Some of them are "basically PETG", but there are some specialty CPEs that are worth considering. For instance, the "High Temperature" like ColorFabb HT or Innovatefil Copolyester Temperature + (long but descriptive name, ain't it?). These beasts can stand 100°C or maybe more (Innovatefil claims to withstand 110°C) with excellent chemical and UV resistance, and no harmful fumes, which makes them excellent substitutes for ABS or ASA. As far as I've experienced, printing CPE is just like printing PETG, just usually hotter and maybe slower, and all the manufacturer's instructions I've found are right on spot.

Re: Need Feedback from i3 mk3 or i3mk3s users

I have had my printer since November last year and built it from a kit and have since then reprinted almost all of the plastic parts. Not because there was something wrong with the supplied printer, but because I wanted to learn more about printing and understanding Slic3r.

I figured if I am going to learn all the ins and outs of 3d printing, I may as well upgrade my printer.

I have been using PETG almost exclusively as I like it's strength and 0.25 nozzles print really well for precise fine detail, but in the last week I have started out with Polycarbonate since some of my PETG parts were beginning to suffer heat effects (Drooping cooling nozzle for instance).

I'm using Rigid.Ink Polycarbonate and I would describe it as PETG on steroids, it also prints with a noticeable improvement in detail over PETG which prints very well as is compared to friends whom have lesser printers and with those lesser printers cannot even manage polycarbonate.

A standard Prusa I3 will print a wider range of materials than a lot of cheaper printers (Better to have and not need than need and not have!) and you will spend more time printing than trying to get a successful print.

Generally you will also be able to print faster with a Prusa printer.

It's not perfect but is being constantly improved whether by PRUSA or users, the work some of the users are putting into improving this printer is sometimes astounding, and they freely share this information with all the other users and Prusa often incorporate these improvements into their printers.

The Prusa community are some of the best behaved and helpful on line forum members of any forum I have ever frequented and don't flame you for asking what might be a stupid question, but generally coax you into asking the right question then giving you the right answers. There is a wealth of information on the Prusa forums about the printers and printing and is well worth reading through.

So in all, The Prusa I3 Mk3 or Mk3s is a damned good flexible printer, it's not perfect and probably never will be for all people as it is designed to be able to at least try to print almost all filaments by multiple manufacturers so here lies the most variability. If you want perfect from the off, you have to buy into a closed source design with rigid control over limited filaments and parts and you will pay through the nose for this, but if your a commercial printer this may be what you want, but you wont learn much or be able to tinker, that is not to say the Prusa i3 cannot achieve the same perfect results or sometimes better than a many £1000s of printer can, just you may have to adjust things or try different filaments to achieve perfect results, but when you do it consistently and repeatedly achieves this.

The Prusa printer is open source and the community is the best support and development platform I have seen and was also one of the reasons I bought into PRUSA and since 3d printing is still a relatively new thing, the whole eco system is continuously developing, and with a Prusa printer you can adapt and change to follow the path it is taking, which you can't do with all printers.

Hope this gives you some food for thought.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Need Feedback from i3 mk3 or i3mk3s users

If you have the "modified" heat break, the theory states hot plastic has been pushed up into the heat break where it expands, cools, then can't be pushed back into the nozzle. Thus, there should be a 2.2mm section in the cold pull, well up into the heatbreak. So far, no one has produced and posted a photo. Then again, maybe my cloud of dust is proof I'm affected - the dust has to settle on something ... lol.

I'll have to measure it, but when removing filament that had been allowed to cool there is clearly a larger area at the end and my clean cold pulls have never had quite the point shown in examples. There is also a considerable amount of filament post change.

I had never thought much of these before, but it's plausible that what is coming out is only right around the 2.2 -> 2 transition.

The video I saw explained the jamming issue as having a correlation to retractions and it also appears that some filaments are worse than others.

I'm certainly no expert, but it seems people are seeing a noticeable improvement with a simple change of the heatbreak. If you aren't going to use the MMU and are having issues it seems like a simple and cheap thing to do.

What does give me pause in the whole idea is the MMU itself. This is supposedly done to improve it's reliability, but since it is pulling the filament all the way out and then inserting the next filament I would expect that to exacerbate this issue and show more jams. Though I guess maybe the full retraction might be carrying any debris along with it?

Re: Need Feedback from i3 mk3 or i3mk3s users

I have a brand new spare Prusa spec heatbreak from e3d at home. I will check it tomorrow morning (I am at work this evening), and try and get some pictures using a USB microscope and stacking, this is where you take multiple pictures whilst pulling focus and stacking them so it shows the complete scene in focus. How well this will work with a tube, I don't know.

I was under the understanding that the difference between standard and Prusa versions was that the Prusa version was polished after machining to reduce the likelihood of filament sticking and dragging during retraction / removal. The only fatter part of a cold pull I have ever seen is in the nozzle and not from the heatbreak.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Need Feedback from i3 mk3 or i3mk3s users

I'll have to measure it, but when removing filament that had been allowed to cool there is clearly a larger area at the end and my clean cold pulls have never had quite the point shown in examples. There is also a considerable amount of filament post change.

In all my cold pulls, the thick spot I see is 2.0 mm - the diameter of the nozzle itself. The wide spot is past the warmed/stretched filament. And I usually get a good cone, and sometimes the nipple out of the 0.4mm portion.

Re: Need Feedback from i3 mk3 or i3mk3s users

All mine don't have the stretched tail (or maybe only a few mm worth) and the bulb at the end consistently measured 2.21mm for me this afternoon after the print failed again.

Re: Need Feedback from i3 mk3 or i3mk3s users

I generally wait to long to pull or set the temp too high so the glass state passes by too fast; the middle of the nozzle gets too warm for a clean pull. Though ... I'm not complaining that I haven't enough experience doing perfect cold pulls like some can do. 😀

Re: Need Feedback from i3 mk3 or i3mk3s users

I bought the i3 MK3 kit . It was fun to put together and i recommend the kit because if you ever do have a problem, you will understand and not be afraid to get into it. I also bought the S upgrade kit when it came out and after 2 days of playing with my live Z it has been working great. I have printed 11 projects with out a problem including one with 8 hrs and one with 5 hrs. I did find that my printer runs better at 90% speed. Great machine.

Re: Need Feedback from i3 mk3 or i3mk3s users

Yep PRUSA spec heatbreak has a step down the middle of the heatbreak it occurs right where the narrow part ends and the thread which screws into the heat block starts and it is narrower in the heatblock than the rest, it's actually a flat step!.

Not the best picture, but this is looking down from the top and is focused on the step which looks dark due to the lighting being diffused from the bottom.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Need Feedback from i3 mk3 or i3mk3s users

It turns out that this is correct, the PRUSA version of the heatbreak is slightly different due to the MMU.

When the filament is removed, it can slightly expand due to the heating, and this makes it difficult if not impossible to thread down the heatbreak a second time. PRUSA has had the coolzone section slightly enlarged to help with this and even though the picture does not show it, there isnt a 90 Deg step, but a taper from the drill used.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.