I can't print larger prints with Prusam

Anyone else have issues, or tips? I've tried higher temperatures than default and lowering/raising the fan.

If I print anything large with Prusament PETG, it stops printing correctly after a while. This goes for both the PETG Galaxy Black and the Carmine Red.

Is there any known batch with contamination or something? Anyone else have issues?

Any other filament (PETG or not) works fine. Not running throught the MMU2 or tightening the extruder tension has no impact. Small prints work fine, so it's really annoying to test. Every single large print fails around 2-3h in.

RE: I can't print larger prints with Prusam

You might try bumping temps up a bit. 5-10C usually helps. When printing big parts, your printer is coming up to speeds that you'll never see at lower speeds. This means the hotend is processing a lot more filament. A better fix is limiting filament throughput to a rate the hotend can handle.

The E3D V6 hotend has a rated capacity of 15mm^3/s, though in practice it's closer to 11.5mm^3/s. Take a look under Filament Settings->Advanced->Print speed override. Maximum Volumetric Speed (MVS) sets a cap on printer speeds. It will print up to the values you specify in settings until it hits the MVS, at which point the slicer will throttle speeds. Depending on the filament, you'll see speeds from 8 for PETG to 15 for PLA. I find the Prusa values a bit over-optimistic and knock them back until I get smooth results. Try adjusting this back to 5mm^3/s for a test and see if that resolves the issue. If so, you can bump it up gradually until you find a number that works consistently. (Note that there is another MVS setting under Print Settings. PrusaSlicer will cap speeds based on the more restrictive setting.)

Slice your part, then examine the speeds in preview mode to see what's going on.

The higher the temperature, the higher the MVS value can be. This benefit may be offset by poor bridging or more stringing, so you have to experiment to find what works best for any particular print.

I get good results using this process. Here's a large part printed with AmazonBasics (now Overture) PETG:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: I can't print larger prints with Prusam

Well, any other PETG seems to works. I started with the PETG from the Prusa shop before they made their own brand (white, black, orange), never had any issues (wider spool, maybe Filamentum made it?). It's only the Prusament PETG I have issues with, and running with the PrusaSlicer stock values or stock values +10°C doesn't help. (+15°C and I get too much stringing for it to be useful.)

I can try lowering the MVS, it's a good idea.

What's a good test for MVS that doesn't require a 3 hour print?

RE: I can't print larger prints with Prusam

[...] I started with the PETG from the Prusa shop before they made their own brand (white, black, orange), never had any issues (wider spool, maybe Filamentum made it?).

The original filament Prusa sold (at least at the time the Mk3 was release) was from Plasty Mldadec in the Czech Republic. They used to have decent costs, even with shipping the the US. Unfortunately, they opened a US warehouse and now charge such high shipping (in the US!) that they are no longer price competitive.

[...] I can try lowering the MVS, it's a good idea.

What's a good test for MVS that doesn't require a 3 hour print?

If you want to calibrate for your hardware with a specific filament, I use this procedure. It takes a few minutes and you'll need a terminal program to talk to the printer. I use OctoPrint for this. The advantage of "free air" testing is that there are no slicer interactions. It's all just straight gcode to the printer so the slicer can't hide or "fix" anything unexpectedly.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: I can't print larger prints with Prusam

If you want to calibrate for your hardware with a specific filament, I use this procedure. It takes a few minutes and you'll need a terminal program to talk to the printer. I use OctoPrint for this. The advantage of "free air" testing is that there are no slicer interactions. It's all just straight gcode to the printer so the slicer can't hide or "fix" anything unexpectedly.

Great test, will do.

RE: I can't print larger prints with Prusam

@bobstro

According to that test I can run the PETG at 240°C at 14mm³/s (F480) before clicking, while it's set in PrusaSlicer at 8mm³/s. That's a lot of margin...

RE: I can't print larger prints with Prusam

[...] According to that test I can run the PETG at 240°C at 14mm³/s (F480) before clicking, while it's set in PrusaSlicer at 8mm³/s. That's a lot of margin...

Prusa seems a tad conservative with PETG, and optimistic with PLA (15mm^3/s). At least you eliminated that as a factor.

Also, that's hotend throughput. You'll want to test for inter-layer adhesion as well. It's always a case of "the lesser of" IME.

Do you experience clicking, or just those poor results? Are you getting lots of filament build-up on the nozzle or hotend?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: I can't print larger prints with Prusam

@bobstro

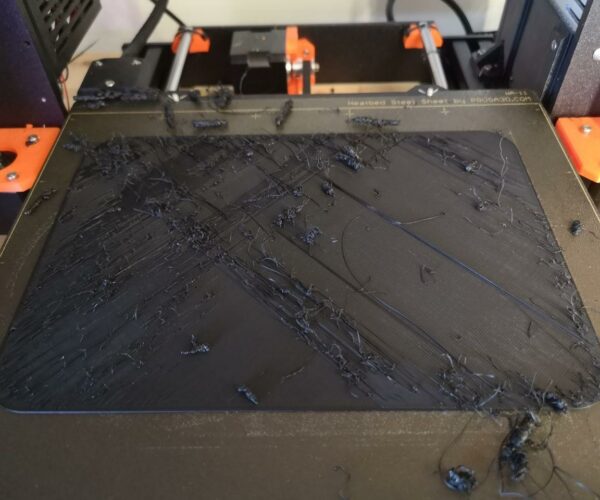

I never noticed any clicking but when it reaches the stage pictured above, there's a lot of rattling so I can't be 100% sure.

There's no buildup what I can notice.

(The same print worked great in ABS at 255°C.)

Will run more tests...

RE: I can't print larger prints with Prusam

Torture test at default parameters (240°C "Prusament PETG") look good, no big issues, bridging is pretty good for PETG, good layer adhesion, slight precision error but this is at 0.2mm SPEED, light curling.