How (or why) do these supports work?

This is in reference to this STL file in this project on Printables.

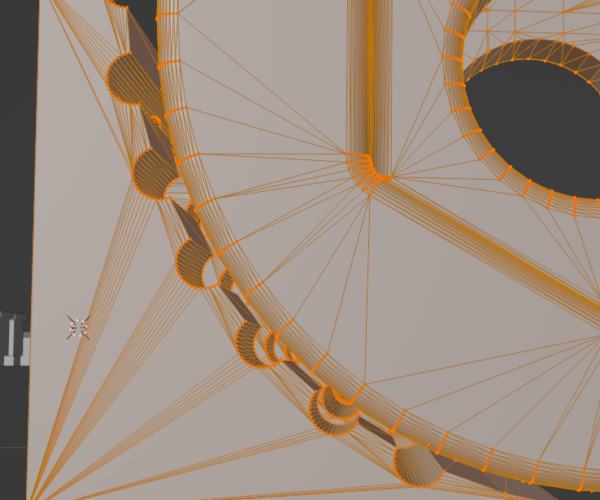

It is a link that can be used as part of an articulated "gooseneck" to use for mounting a camera on a 3D printer. The designer includes files for this item that have supports and don't have supports. Here are some shots of part of the item with the supports he included in the STL file. (Screenshots are of Blender.)

The above is in Edit Mode, which is used for editing one object at a time. You can see the support on the left, with an arc that matches the curve of the object to be printed. Note the support does NOT touch the printed object at all.

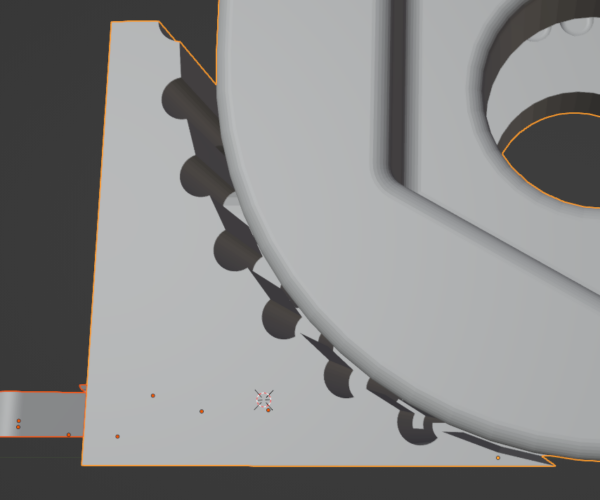

Another shot, in Object mode. (Ignore the red dots - didn't see them until I started posting this - and ignore the shape in the background on the left.) Again, you can see there is no contact between the support and the printed object.

A view showing more of the supports and object for context. Also, this does a good job of showing that the printed object does not actually touch the print bed. So it isn't touching the bed or supports in the STL file, but it prints properly. I'm not at all clear why, when the printhead is extruding the first layer of this item, it's able to do much with it, since the item doesn't touch the print bed. I'm not sure why the filament stays in place when it comes out of the print head.

When I print, I do have to remove the supports from the object, but they're easier to remove and clean up after than if I just specify for PrusaSlicer to generate its own supports. It works.

How or why does it work and not leave me a mess with layers of the object not even being printed until the print head is more than the 1st layer above the print bed?

RE:

Supports generated by PS dont touch the object either. Not if you want to be able to remove them. So user designed supports dont either. Nothing unusual in this. You are setting a contact z distance of 0.2 or more on your prusa sliced supports aren't you ? 0.2 is a safe distance for most materials if you want them to be easily removable. That's with the current grid or snug options although it does depends on model geometry as to what is most suitable.

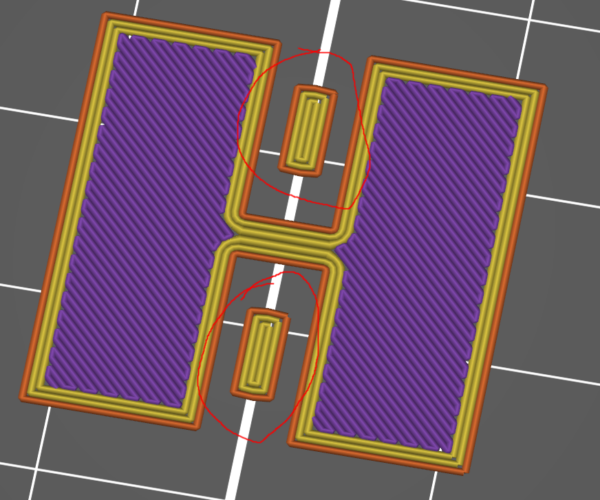

Also when I load that stl you linked to and slice it the bottom of the actual link DOES touch the bed, in 2 areas and with normal bed adhesion with large enough contact patch to stick and print. Areas circled in red. While in Blender only the very bottom verts of the curve are in line with the other bottom verts that make up the supports base you have to remember that a slicer 'chops' up things into layers. If you separate out a 0.2mm section then theres enough (just) to register for the slicing engine. If there wasnt then the usual 'fix' would be to trim 0.2 from the bottom of the model to give you a larger area from further up the curve.

Also the printable entry does not contain any project file. That would be a Prusa Slicer 3mf file. A project contains parts and sliced settings all laid out on the bed with any suggested modifiers etc all baked in. The user has uploaded some presliced gcode files, that do indicate he is using petg (not pla as in the description) and using either 0.2 or 0.15 layer heights. Pre sliced gcode is not as good/flexible as a project.

Personally if I was printing I would use the without supports stl and define the areas i wanted supporting in PS using the paint tool and then use supports for enforcers only. That would use less material and print quicker and still give the enough support to print things. Then again I am used to the paint on support tool and know what my printer is capable of when it comes to bed adhesion.

RE: How (or why) do these supports work?

Supports generated by PS dont touch the object either.

This baffles me, if the supported face isn't touching the support then how is it supported?

RE: How (or why) do these supports work?

Come on Towlerg you’ve been around long enough using the software now.

Gravity does its thing and it sags so it’s in contact. It will do that regardless of the contact distance. The problem if you don’t have some distance is that it then becomes almost impossible to remove from the part.

It’s a balancing game of acceptable sagging vs support removal.

That’s why soluble supports are zero gap and touch, you don’t have to worry about them fusing.

It’s also why you see people pausing on large flat areas of the top support and using things like sharpie markers to create a barrier between the top contact layer and bottom of a part. They can then get away with touching. Unfortunately that’s a manual process so not part of a slicer but I’ve seen vids of it in process and it seems to work.

Pity there’s not a current viable way to add a sharpie extruder and automate it. People are tinkering though.

It will be interesting to see how the new organic supports in 2.6 do with contact distances and material types.

RE: How (or why) do these supports work?

you’ve been around long enough using the software now

Ah, you'd thinks so but apparently not. It really didn't occur to me that is sagged, of course it sagged, a four your old could have worked that out.

Thanks for explaining.

RE: How (or why) do these supports work?

You almost always want to use painted on supports, just for the learning that it provides. Sure you'll have some failed supports, but if you stick with it, you'll learn much more about when you don't even need supports. Remember that printers can bridge a certain distance without any support, even though the auto-supports will add something. Often completely unnecessary. It will also get you analyzing your models more using the sliders at the right/bottom to see how the head travels and in understanding why many things work without supports.

RE: How (or why) do these supports work?

Sorry for the delay in replying. It took me time to think about this and I was dealing with other stuff. It took me time to work out, in my head, what I understood and didn't understand.

Supports generated by PS dont touch the object either. Not if you want to be able to remove them. So user designed supports dont either. Nothing unusual in this. You are setting a contact z distance of 0.2 or more on your prusa sliced supports aren't you ? 0.2 is a safe distance for most materials if you want them to be easily removable. That's with the current grid or snug options although it does depends on model geometry as to what is most suitable.

So contact distance also applies to supports? Okay, new to me, but I'm still learning how to use supports and how they work. (Other than just holding things up - such as what kinds of support, how much support, and how to make them easier to detach and still being functional.)

Come on Towlerg you’ve been around long enough using the software now.

He may have been using this long enough, but him posing the question helped me think through this. I've activated supports in PS and used them. I generally set it to put supports only where I put support enforcers, since I've already noticed it adding supports where they weren't needed.

Gravity does its thing and it sags so it’s in contact. It will do that regardless of the contact distance. The problem if you don’t have some distance is that it then becomes almost impossible to remove from the part.

It’s a balancing game of acceptable sagging vs support removal.

So any time there are supports, the surface above them will sag? Let me go with a big T for an example. I know if I were printing a T, I'd print it on the side, but for learning purposes, let's say I have to print it upright and there are no serifs - just a simple upright and crossbar on the top. And let's say it's part of something bigger so it has to be able to slide into place in something else. So if I print it, standing up, and make supports for the crossbar, then if I'm making them on my own, there needs to be a gap between the top of the supports and the crossbar and the bar will sag no matter what? So if I need a precision fit, then I'd have to plan for that sagging in my design?

And, continuing to try to think this through, if the Z contact distance is 0.2mm, then I can count on the crossbars sagging down that 0.2mm. When that happens, aren't they still going to attach to the supports below as the filament dries? I don't see why the contact distance makes a difference and makes the object being supported less connected to the supports below it.

The user has uploaded some presliced gcode files, that do indicate he is using petg (not pla as in the description) and using either 0.2 or 0.15 layer heights. Pre sliced gcode is not as good/flexible as a project.

Personally if I was printing I would use the without supports stl and define the areas i wanted supporting in PS using the paint tool and then use supports for enforcers only.

A few questions and comments related to this. I'm in a humid area, I've asked about that elsewhere, when I've had filament snap. I've started with minimal filament spools, although I have a few more spool than I'm using now that are still in vacuum sealed bags. I'm working with just PLA for now, until I can set up a storage system and a drier so I can mitigate humidity issues. I'll be working with PETG as a next step, but, for now, I'm trying to avoid ordering or opening more spools. I still have a few things to do before I can get to the storage and drier issues.

You talk about painting on supports. I've been using support enforcers. Assuming, in both cases, I'm using supports only where I have enforcers, it seems to me the only difference between painting and using support enforcers is the shape - that I can be more precise if I only want supports in a small irregularly shaped area if I paint them on and that if I use the pre-defined enforcer shapes, I'm limited to only those shapes. Other than that, is there a difference in the final output between using pre-defined enforcers and painting them on?

It’s also why you see people pausing on large flat areas of the top support and using things like sharpie markers to create a barrier between the top contact layer and bottom of a part. They can then get away with touching. Unfortunately that’s a manual process so not part of a slicer but I’ve seen vids of it in process and it seems to work.

It this as simple as watching the printer and, when it finishes the level with the top of the supports, you pause the printer, use a Sharpie to color the tops of the supports, then continue the print? And, with the hot filament, won't the color of the Sharpie end up on the bottom supported surface in the long run. In other words, I can't just clean it off, right?

It will be interesting to see how the new organic supports in 2.6 do with contact distances and material types.

Has there been any word on when to expect 2.6? There are one or two features I've heard about that I'm looking forward to. (One will be to no longer get notifications about something looking like a logo on about 90% of what I print!)

You almost always want to use painted on supports, just for the learning that it provides.

When you mention painted on (and this relates to my questions above about painting), do you see a difference in using painting vs. pre-defined support enforcer blocks?

RE: How (or why) do these supports work?

I am using the same articulated arm for my Pi cameras and to be honest there's a lot about the geometries that just don't work super well for 3d printing, at least not with the PETG that I have been using. Those rounded corners don't like to print cleanly as overhangs, and I haven't seen a lot of difference between using the files with the built in supports, vs. painting them on myself.

RE: How (or why) do these supports work?

Functionally a support enforcer modifier and a painted on support area are the same. Both are designating mesh faces on the model where you would like support to be placed. That does not mean you will get support on those faces for certain though. Once areas are marked the support algorithm takes over and actually generates them (or not) depending on all your other support settings. For example you can define an area on top of a model and it wont get support as its not a bottom surface. That's a rather obvious example but it illustrates a point. Things like pattern spacing, closing distances etc can all effect what support in generated in conjunction with your defined areas. As another example I have seen areas defined that were very small that got no support generated to them as the pattern spacing and closing radius were too large to make the area supportable. As with most tools, the more you use it and experiment the more you will learn how it works.

I used to use enforcer modifiers all the time, with painting I just don't need to anymore. Once you learn how the brush tools work its soo much easier to define areas with them. For example the smart brush would be able to define your undersides on your T example with 2 clicks. The devs obviously put a lot of work into them and its paid off.

The one thing I never do is use the autogenerated supports option. With grid it produces way way too much support (and always has) and with snug its still too much generally.

Feel free to configure different contact z distances on some test prints to see what difference it makes to how easy support removal is. Its what anyone who wants to learn ends up doing anyway. Different materials all sag differently under cooling and temperature conditions and they all have different inter layer adhesions which makes a difference on how hard they are to remove too. The 'general' wisdom is between 0.2-0.25 gets you reasonable results. PLA and PETG will behave differently though so it is best to get empirical data with your own tests. Personally with snug supports I can generally use 0.15 without problem on PLA and with my tuned profiles.

Other settings like the number of interface layers also make a difference in how easily things can be removed. I use 4 interface layers in general as I find a thicker denser interface doesn't break apart as much and peels away in larger areas which in practice means less removal of left behind strands making cleanup quicker and easier. There are many variables and the approaches can vary slightly depending on model too.

And yes, designers have to take the medium that's going to be used to create their parts into consideration if they want/need parts that fit together or mate with other non printed parts. For example screw holes need clearance, same with parts in X/Y. In Z you need to make sure the layer height you are using can actually match the part height (or use a few layers of variable layer heights to get a match) etc. Yes bridges and overhangs need that consideration. That's one of the problems with downloaded designs, I could tune things for my printer and get snap together parts and upload them and on someone else's setup they might need sanding. Design for them and then the fit might be loose for others. It's something you learn over time, again through either just use or designing/using specific test parts.

For your T crossbar example though if you were designing them yourself then depending on the crossbar distance and how good your printers cooling was you could add extra verticals on the tips and then bridge the underside of them. That way there wouldn't be any support under them at all, just a pylon you would snap off afterwards. Its the same type of design technique you can use for counterbore holes that face down. Instead of support you would design in a 1 layer thick patch over the holes so it can be bridged and then you would just punch out the single layer afterwards. Saves lots of time and material. This all comes down to designing for the production medium. There are countless techniques to learn.

Just remember even if you tune things to a fine level that all it takes is filament spool variance to throw it all out. That's one of the reasons to physically measure the filament diameter average on every roll and plug that value into the filament profile for your slice. Every volume calculation is based on filament diameter and few people change the 1.75 in the filament profiles, they just go and play with extrusion multipliers. When you consider that its common to have filaments that are 1.72-1.76mm in actual diameter you start to see why people report problems with under extrusion.

The setting 'Top contact Z distance' is only to Define a distance between the support interface and the bottom of a model. What did you think it controlled as a matter of interest ?

The bottom contact z distance does the same for the bottom of supports that need to be printed on top of the model.

To use your T example the support interface would be generated 0.2 below the bottom of your outward sections if it was set to 0.2. The XY separation distance setting controls how close the vertical part of supports are allowed to get to the perimeters of the object. This can interact with contact z on sloped areas and give results that you don't want as it might not be able to fulfil both conditions which is why checking the slice preview is such an important step in the process.

I don't watch all the prusa live casts on you tube but on a recent one where they were showing off the organic supports it was mentioned that 2.6 wasn't expected until after the holiday season as there were still other features that needed work. I've got a notification watch setup for releases on the github repository so when it is released I can grab the alpha. It will come when it comes. No point stressing over it.

btw for the sharpie technique I found this on a search I have never tried it myself, I just remember seeing it on hack-a-day ages ago.

RE: How (or why) do these supports work?

First, I know it's been a while. Christmas happened - wrapping, long trips, lack of time for printing.... I just want to make it clear I really do appreciate all the help on this forum, even if it takes me a while to reply. Often I leave a tab open to a topic like this so I can come back and reread posts over a few days so I get a better understanding of what's going on or so it helps me remember what I'm reading. (@Neophyl, that's definitely true with your comments. You provide a lot of useful information and sometimes I need to read through it, think about it, and come back to it later. All your help and information and explanations are a big help!)

I am using the same articulated arm for my Pi cameras and to be honest there's a lot about the geometries that just don't work super well for 3d printing, at least not with the PETG that I have been using.

I'm printing with PLA. Haven't started on PETG yet, but I'm also not buying more filament until I have storage bins with desiccant in them and something to dry out my filaments. In this area, now, we have what we call low humidity - very low. It's between 30-40% inside, which I understand too high for filament. I also need something to dry filament out. (I've discussed this on another thread, but I'm open to suggestions.) The articulated mount system has printed just fine in PLA. The problem is the ball joint mount is great at first, but after it's been moved around, it's too loose. I've created my own handle and mount parts for my Prusa and my Ender 3 Pro. Both of those attach to the print bed and come out in the front so I can use them as a handle to move the bed back and forth and as a mount so my camera is mounted on the bed, not the frame. (Cameras that don't move with the bed make me dizzy.) These parts were my first attempt at designing and making complex parts to print. You can tell they're not part of the articulated system, since I didn't bevel any corners or edges. (I was still just learning how to keep the mesh in good shape as I edited it and used modifiers on it in Blender.)

Things like pattern spacing, closing distances etc can all effect what support in generated in conjunction with your defined areas.

I've been using the support enforcers. Maybe it was instinct to keep those areas away from other parts on the bed, but that's helpful and good to know.

As another example I have seen areas defined that were very small that got no support generated to them as the pattern spacing and closing radius were too large to make the area supportable. As with most tools, the more you use it and experiment the more you will learn how it works.

Supports are also easy to experiment with inside PS, and I do that a lot. Of course, there's also the bigger issue of what I see in PS and what that translates to when I print!

Once you learn how the brush tools work its soo much easier to define areas with them. For example the smart brush would be able to define your undersides on your T example with 2 clicks.

I've experimented with the brush - I didn't realize there was a smart brush function. That's something I'm looking forward to learning about, but it won't be right away. I'm still experimenting with the pre-shaped enforcers. I'm also learning a LOT about design tricks, too, to print objects that don't need support and can be printed in multiple parts, then assembled.

One thing I've found that's a pain is supports near a screw thread - whether it's male or female. It's almost impossible to clean those and make the threaded part useable. I also had some other objects where supports were tough to deal with. It gave me the wrong idea about how they worked and you cleared a lot of that up for me. Before Christmas, I was printing out a triceratops drawer knob for my grandson and that required supports. This time, while cleaning it up, I could see what was going on. The supports were attached to some surfaces, but NOT to the one they were supporting.

The one thing I never do is use the autogenerated supports option. With grid it produces way way too much support (and always has) and with snug its still too much generally.

I did that once. Never again.

Feel free to configure different contact z distances on some test prints to see what difference it makes to how easy support removal is. Its what anyone who wants to learn ends up doing anyway.

I do like experimenting, but I also like asking questions so I have a bit more information going in - I guess it's just all part of the learning process!

Personally with snug supports I can generally use 0.15 without problem on PLA and with my tuned profiles.

If you're designing an object, do you ever take the expected sag into account? For instance, if you're using 0.15mm for the gap, do you consider trying to put that overhand or bridge a bit higher in the design? Or is that amount so small that it's hard to account for with the thickness of a layer?

Its the same type of design technique you can use for counterbore holes that face down.

For some of the drawer knobs I made for my grandson, they were in 2 parts and used threads to screw the two parts together. I ran into an issue with the female threaded part. The diameter of the hole was big enough to cause some sagging and it had to be printed so the opening of the hole was on the print bed. I edited the mesh on that part so there was a small cone above the screw hole. The cone top slanted at a 45° angle, so sagging wasn't an issue after. I did that.

The setting 'Top contact Z distance' is only to Define a distance between the support interface and the bottom of a model. What did you think it controlled as a matter of interest ?

I wasn't sure - until I posed this, the only thing I had done with supports is to start using enforcers because auto-generated supports were a mess.

RE: How (or why) do these supports work?

I also need something to dry filament out. (I've discussed this on another thread, but I'm open to suggestions.)

PrintDry dot com is currently running a 25% off sale. Unsure for how much longer.

Cheers

RE: How (or why) do these supports work?

I also need something to dry filament out. (I've discussed this on another thread, but I'm open to suggestions.)

PrintDry dot com is currently running a 25% off sale. Unsure for how much longer.

Cheers

Thanks! I have them in an open tab now, haven't had time to read through anything. Hoping the sale runs through the week so I have a few days to look things over.

RE: How (or why) do these supports work?

I picked up a ‘standard’ PrintDry Pro’ on sale back in August. It works very well. Maybe a bit noisy with the fan but it’s just white noise to me.

If you’re interested, don’t wait too long, their sales tend to come and go pretty quickly and 25% off is the best I’ve seen from them.

Cheers