Help - filament jams/slips on print start, filament change needed to continue

Hi!

During 2020 my MK3 printer suddenly started having the following issue.

Specially at the start of each print, the extruder would slip (making some "tak tak tak" noises) and plastic stops coming out of the nozzle entirely.

I was suggested to change the PFTE tube, and so I did. However, after a while the problem reappeared. I changed it again, twice, and the problem still persists.

I've found that this can be patched up on each print, by making a filament change (through the controls on the front LCD) during the print, when the slipping noise appears.

The slipping happens almost every time at the start of the print, sometimes during the first layer, and mid-way through the print every now and then.

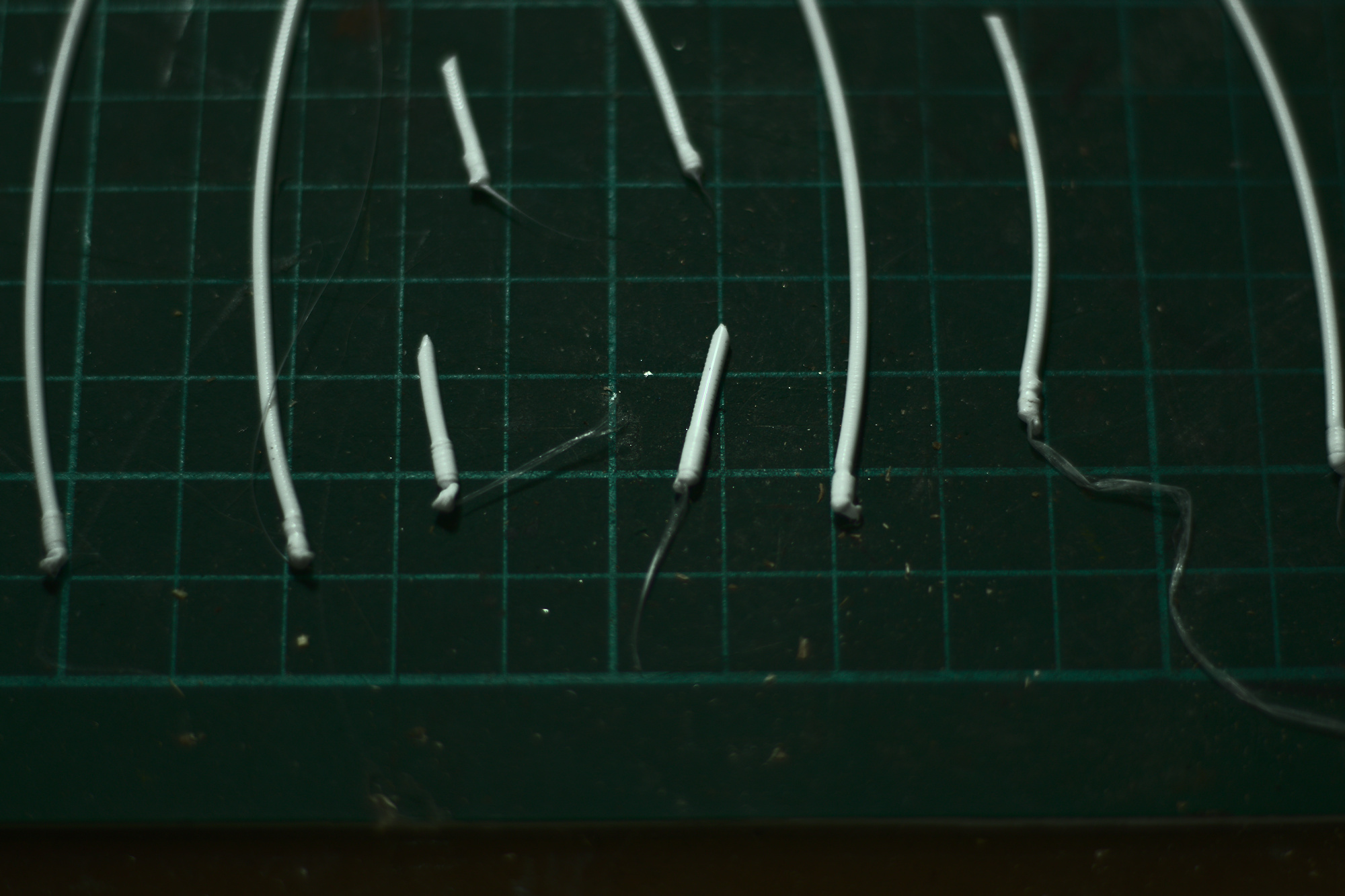

My main clue is the shape of the filament's end when I remove it during the change. I cut them off and keep some for the record (see attached image or this album: https://photos.app.goo.gl/EBxfnJkYvPMoT1ta8 ).

Things I've tried:

- Replacing the PFTE tube.

- Cleaning the nozzle with the needle.

- Raising the extruder temperature.

- Doing "cold-pulls" to remove whatever stuff may be clogging the extruder.

My usage of the printer:

- I print intensely on a few weeks over the year, so it's idle most of the time.

- I use PLA almost exclusively, always from the same brand. I have used PETG and ABS just to try.

I'm clueless about this, and need some help to troubleshoot.

Thanks!

RE:

Did you get the right PTFE? There are 3 different types of PTFE for MK3, MK3S and MK3S+

Did you install it correctly? All the way in, correct side down/up.

If PTFE is not the problem, the idler tension is next on the list: https://help.prusa3d.com/article/idler-screw-tension_177367

If your first layer is set way too low and the nozzle is blocked by the print bed you get the mentioned tak-tak noise as well.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE:

Hi Robin! Thanks for the quick reply 🙂

Did you get the right PTFE? There are 3 different types of PTFE for MK3, MK3S and MK3S+

I think so! I followed this guide: https://help.prusa3d.com/guide/how-to-replace-a-ptfe-tube-mk3-mk2-5_17360

If PTFE is not the problem, the idler tension is next on the list

I have also tried tightening and loosening the idler tension, even while the filament is slipping, to no improvement :/

My feeling is that the end of the filament gets wider (in diameter) for some reason, and then jams (either on the extruder or in the tube somehow). I say this because of the shape of the ends of the filament when I remove it.

Also, just once, I needed to remove the extruder entirely and replace the PTFE tube, because the filament got jammed in the tube (on the extruder-end) and would not move at all.

RE: Help - filament jams/slips on print start, filament change needed to continue

Extra: I just read the comments in the PTFE guide, saying that the geometry of the trims might be inaccurate.

RE: Help - filament jams/slips on print start, filament change needed to continue

I use this: https://www.printables.com/model/34035-ptfe-multitool

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Help - filament jams/slips on print start, filament change needed to continue

You can do the following test.Turn on the printer and make sure the nozzle (Z) is at 100mm high.

Now choose the load filament option and follow the steps.

When the purge option is executed, do you also hear the clicking sound or is that okay?

If no clicking sound is heard during this test, the nozzle is too close to the bed and needs to be recalibrated.

RE: Help - filament jams/slips on print start, filament change needed to continue

Nice jig, thanks 🙂

I did't have a pencil shaprpener around, so I used this one https://www.thingiverse.com/thing:3749528/files

Not as great, but it got the job done.

However there was only slight improvement, and eventually I ran into the same problem.

This is what's printed when the filament starts slipping / gets jammed / something.

Sample 1: the print started at the bottom of the pic, then the filament started slipping, and then I made a manual filament change, after which the print continued.

Sample 2: same as above, but this time the problem appeared at least 5 times during the first layer (only 4 failures appear in the image).

I ordered a new nozzle in case that's the problem.

But I still don't know what may be happening.

RE:

If no clicking sound is heard during this test, the nozzle is too close to the bed and needs to be recalibrated.

Hi Rene! thanks for your reply.

Yes that could have been the case, but the recallibraton didn't help.

My z-adjust seems fine (I followed the usual procedure: https://help.prusa3d.com/article/live-adjust-z_112427).

I also tried increasing the z-adjustment (to a more positive value) but it also didn't help.

RE: Help - filament jams/slips on print start, filament change needed to continue

Well, I finally got the new nozzle, installed it, and the problem went away (for now).

The original 0.4 mm nozzle had been in operation since March 2018, about 4 years. Let it rest in peace.

Though, if I find the time, I'll try to clean it, run some tests (such as these), and report back.

Thanks for your help 🙂

RE: Help - filament jams/slips on print start, filament change needed to continue

Hi all! I finally found the cause of the issue.

Searching the internet for "heatbreak jams prusa" immediately returns a bunch of posts with the exact same symptoms.

There is even a video about this by 3D Printing Nerd: "NO MORE JAMS on the Prusa i3 mk3 3D Printer!"

I am surprised that prusa support never replied to my emails with a solution, even though it is a well known problem.

- https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/prusa-edition-heat-break-easily-jam-clog-with-pla/paged/8/

- https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/mk3-mk3s-prusa-heat-break/

I'm replying now in case it helps someone like me get on track.

Also, I'll add how I got to the right search terms. After a serious jam I was forced to disassemble the hotend entirely, and by mere conincidence found this hardened gunk between the heater block and the heat sink: https://imgur.com/a/vRNxAmK

The material completely surrounded the heatbreak, which in turn may have helped heat creep up to the heat sink, causing these jams with charachteristic shapes in the filament end (pics in the first post).

I'm happy I found the issue. I hope I get many more years out of this fantastic printer. Thanks everyone!