Great run...then persistent fail

MK3S+

I've been running multiple instances (4) of the part below for days now, multiple colors (PLA) virtually around the clock with no problems.

I tried increasing the instances per print anywhere from 5 to 12, and they would always fail to adhere properly on the second instance during printing, so I abandoned that plan. However, since last trying that, now it won't adhere at all, even with runs of 1 or 4 instances which have previously worked just fine.

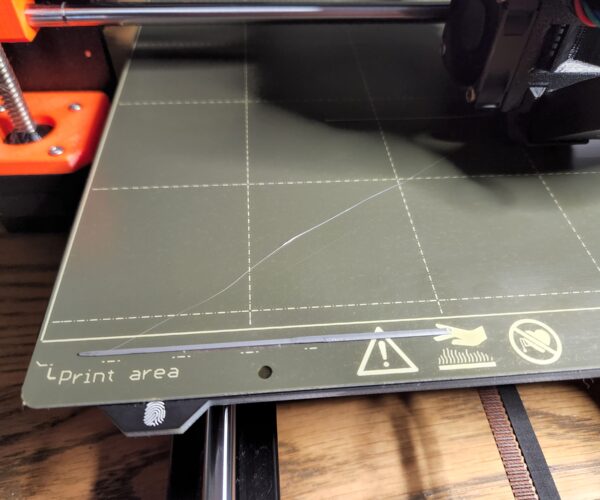

It lays down the initial bead just fine (usually, sometimes that doesn't adhere correctly either), then strings to the perimeter bead:

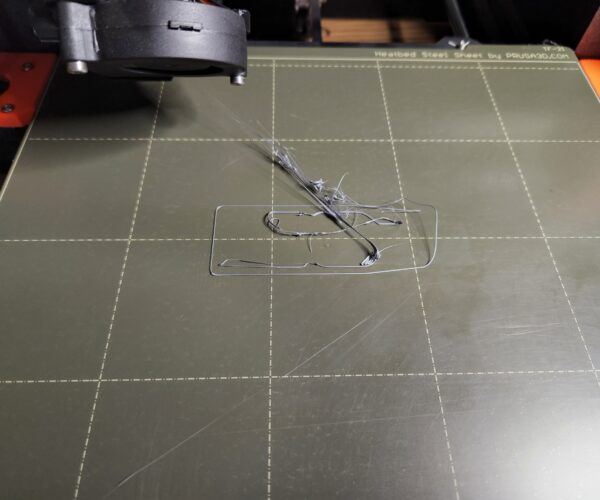

Then I just get this:

I have changed literally nothing between the prints that worked to the prints that didn't. Previous adhesion problems were fixed with a thorough washing of the steel plate with detergent and water, which I've done. Printing of other objects including the sample Prusa logo and a simple cube deliver mixed results.

I recently did a full calibration, cleaning and lubrication after some other problems, but it has been working well since then.

Appreciate any help.

RE: Great run...then persistent fail

Well that live z adjustment looks like its not low enough in your last pic. I'd recheck it. Its always possible something has worked loose and changed relative positioning. Id ne checking that the nozzle is still tight, pinda sensor position etc. If the sensor has dropped a bit then it will detect the bed sooner and so stop the nozzle further away.

RE: Great run...then persistent fail

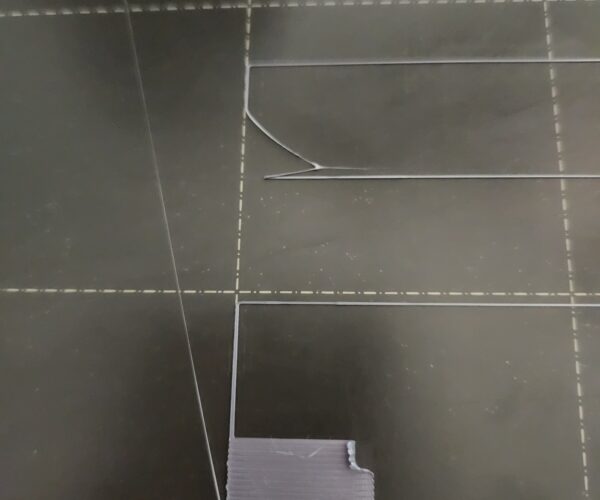

I had a similar thought about the live Z, so I worked with it and brought it negative from -0.988 to -1.030, but I still have some adherence problems and it looks like it isn't consistent throughout the zigzag pattern. There is also that pulled up area in the upper right corner of the final calibration pattern:

The PINDA feels firm, and that screw has not worked loose best I can tell. The nozzle is also tight as it has been.