Gluing parts

Hi..

I have printed a storage compartment for my motorised wheelchair. It'll go under the seat and is in a few parts. It may contain things that have some weight so I don't want it to fall apart when I'm out and about. I've primed it and spray painted it black.

I'm now at the stage where I need to put it together. What I'm not sure about is whether I need to sand the paint off the areas that will be glued together.

I'll be using PLA Gloop. I'd assume that gluing parts where the glue is not actually touching the printed plastic, but a couple of coats of paint isn't ideal

Any advice?

Thanks

It's always easier to glue clean surfaces.

PLA can be solvent welded with acetone - no need for goop. It accepts cyanoacrylate well. It can be friction welded but that does spoil the finish, and at a pinch it can be joined by using a 3d pen like a wire-fed MIG or TIG welder.

Large areas can be glued with contact adhesive but avid hot glue guns and water based adhesives.

Cheerio,

RE: Gluing parts

My go-to adhesives for PLA are as follows:

1. For a more forgiving but still strong bond, Aileen's The Ultimate Multi Surface adhesive. Very good for flat surfaces and larger pieces. I use this quite a bit to glue such things as model railroad building pieces together, batteries, small circuit boards, small display models, to 3d printed pieces. Glued items can be coaxed to separate cleanly, but with patience. Most large hobby shops, such as Michael's, will have it.

2. For a very firm bond that will stay stuck no matter what, Dr. Mikes Model and Crafter Glue. This is a liquid type of super glue that will give you a few seconds to position pieces before it sets HARD AND FAST. You will not get two plastic pieces joined with this to separate without sacrificing at least one. Their web site appears to be down today (drmikesglue.com). Some local train and hobby shops will have this. It's available at most large train shows.

RE: Gluing parts

" It may contain things that have some weight so I don't want it to fall apart when I'm out and about. I've primed it and spray painted it black. "

I concur with the glue comments above, however.

1)

If the parts are already painted the to-be glued surfaces should be cleaned and sanded to provide a strong grip surface on the PLA, not the paint.

2)

Since you will have "things with some weight" to carry you should consider having small holes drilled to string zip ties in addition to the glue between the parts and the mounting below the seat. Should the glue fail or the seat mounting the zip ties will at least hold the structure in unison instead of spilling the content all over the place in case of a sudden failure due to a bump.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Gluing parts

I very seldom paint anything I 3d print, but I agree that the surfaces to be glued should be bare plastic, as paint will most likely release before the adhesives do.

As an aside, I remember a thread a while back on painting PLA, and IIRC, the bottom line was that a plastic primer was almost mandatory before the color coat.

RE:

I know the topic is Gluing parts however since it's already painted, Maybe a double sided rivet? Basically a Rivet with a small special washer on the expanded side.

The Filament Whisperer

RE: Gluing parts

Thanks all !

😉

RE: Gluing parts

I know the topic is Gluing parts however since it's already painted, Maybe a double sided rivet? Basically a Rivet with a small special washer on the expanded side.

What works for me, for pieces that need more of solid joining than glue will provide, is to use small (as in 1-3mm) machine screws, and draft holes such that one side is a clearance fit and the other (use trial and error with a test print for the specific filament and settings) can be force-tapped.

This holds amazingly well, plus the pieces can easily be disassembled.

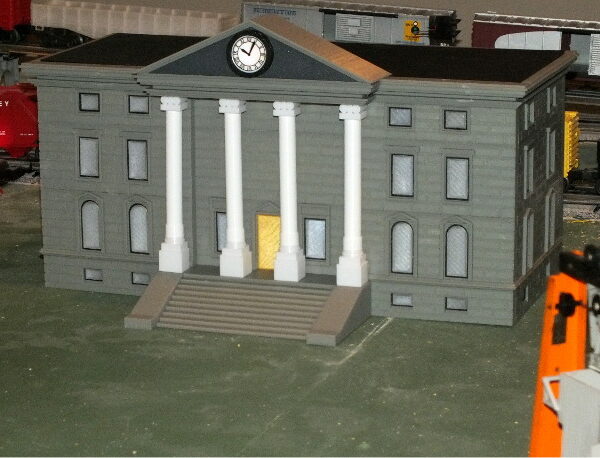

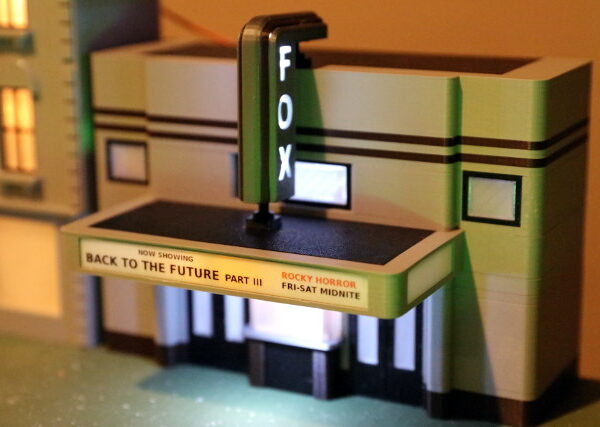

For larger models (such as below), I've found that registration pegs and maybe a single machine screw on the joints most likely to flex will make the entire assembly very sturdy. (Anybody recognize that building? Hint: Look at the time.) 😉

RE: Gluing parts

In hindsight.... I should have put masking tape over the gluing areas.... arse

🙄

RE: Gluing parts

In hindsight.... I should have put masking tape over the gluing areas.... arse

🙄

And hey, don't be afraid to sacrifice a piece and reprint it. Filament is relatively cheap. (Unless you're talking about a huge multi-day print, that is.)

RE:

Ha... well, that's not going to happen... yeah, they took a while to print.

They're quite large pieces and I've done them for both sides of the seat.

I'm sat here now sanding the paint off.

Anything come to mind that I can use to 'eat away' at the layers of paint but not affect the plastic?

Any household items... I want to get this done and on the chair asap. Been designing this thing on and off for 2 years and I'm sick of it

use to 'eat away' at the layers of paint but not affect the plastic?

Anything that will react with the paint or dissolve it will leave residues that themselves will have to be cleaned away... mechanical removal is best.

Been designing this thing on and off for 2 years

The old name for 3D printing was 'Rapid Prototyping'. Nothing has ever been designed that could not be improved, somehow, however marginally. Regard anything you make as a prototype. Regard any part you install or use as a test piece. Some of my parts are in their sixth year of testing...

Regard any assembly failure as a test of the build and use instructions that will go with the part whether published or not, and document them.

I had a request to replace a four year old TPU part from a yacht recently because it had discoloured. With the new part will go the added instruction 'Do not clean with holystone' as the abraded surface grabs all the fine particles from deckwashing.

In a few months, after real-world use, you may well find ways to improve the part. In due course, once you have had a stable, tested, design for long enough; you may be able to offer the design for others with lesser design skills to print for themselves. The painting and gluing instructions have already started writing themselves...

3D printing is a brilliant way to iterate a design and in the long run the result should be a better product.

Onwards and upwards!

Cheerio,

RE:

Thanks!

Your reply made this come to mind 😆 👍

RE: Gluing parts

Without the benefit of seeing your design, I'll chime in with the technique I use frequently to join seperate parts of an assembly. I "print" in slightly undersized holes in the mating surfaces (use at least four perimeters) and insert "rolled" or "tension" pins. Not recommended if the parts are in actual tension wirh respect to each other, but this may be something you can design around with orientations and cut planes. Has the added advantage that you can frequently make the holes "blind" so that the pins are totally hidden cosmetically.

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

RE: Gluing parts

I was the one who had the problem with paint. Primer helped a bit but the real issue was that the paint would never totally dry on PLA plastic, always had a sticky tacky surface.

Tried baking after painting, still tacky. Tried talcum powder, better but still got tacky after a while.

What did the trick was a thin coat of Pledge Floor Gloss. Gave a better surface luster too.

Formation dance routine everybody?

... five six seven eight, right kick, buck and wing...

Cheerio,

RE: Gluing parts

At least it wasn't a Chitty movie, 🤔 well it wasn't Bedknobs and Broomsticks anyway. 😉

The Filament Whisperer

RE: Gluing parts

Ok, for those of you that don't understand, or even have the desire to understand, the movie the original post was from was Chitty chitty Bang bang a very well thought out and made classic movie. I recognized this right off, for the Millennial's this was a movie we all saw in our youth, and it was a great movie. I made sure my kids saw this as they were growing up, and for the Millennial's I'm sorry the world and your parents messed this up for you.

Your screwed and your going to have to fight to get what we used to get out of life without a fight.

Sorry, blame your parents, they voted this way. At least in the USA.

Swiss_Cheese

The Filament Whisperer

RE: Gluing parts

@jsw - that looks just like Hill Valley's clock tower. Pretty sure you have the flux capacitor and DeLorean somewhere there in your collection as well - 😉