Gaps in surface next to holes

Hi, sorry about the odd title 🙂

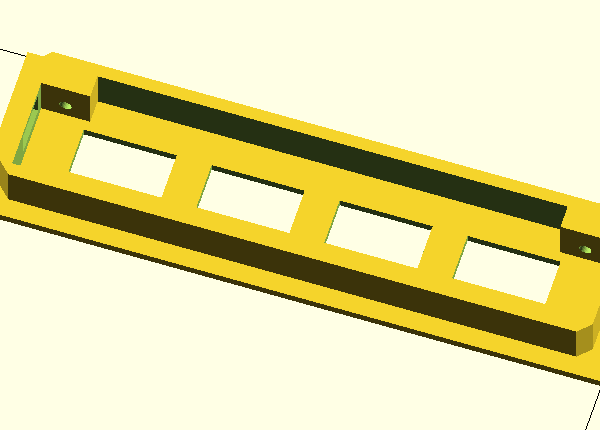

I am trying to print the following.

It comes out with vertical gaps around the cutouts :-

I have tried changing the perimeter settings, I reverted to a previous version of the slicer, I tried vase printing, I tried making the face thicker, I even tried repairing the STL. The gaps don't show up in the slicer when I rotate and view the surface and they don't show up on the model (created with openscad - literally it's a cube with four cubes subtracted from it so there is nothing to go amiss there).

Anybody any ideas on what else to try ?

Regards

S

RE: Gaps in surface next to holes

I probably should have added, it's a stock Prusa i3 Mk3S+ running the latest firmware and now latest PrusaSlicr. Printing with generic PET-G

It probably needs calibrating again as well but I don't think that's the problem.

Regards,

S

RE: Gaps in surface next to holes

Looks like a mechanical problem (belt or hotend loose) or maybe your infill overlap is low. Did you try rotating the model 90deg to see if the issue follows that?

RE: Gaps in surface next to holes

Can you zip the project file, and add it to your next post?

you will need to Zip compress the file, in order to attach it.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Gaps in surface next to holes

@3dp-micro

Hi,

Thank you for the quick reply. I hadn't considered a mechanical problem. I had a good check and all axes move freely and the hotend is clean. I rotated the job and moved it to the diagonally opposite quadrant on the bed, it was NE, it's now SE.

It still has the holes though they are now along the long edge of the cutouts.

I think if it was a mechanical problem, the fault would appear along the whole length rather than parallel with just two cutouts and also occur between the cutouts.

Good suggestion though - Chapeau 🙂

RE: Gaps in surface next to holes

@joantabb

Hi,

Thank you for a quick reply. I have attached the .stl and gcode in a zip file. The STL is produced by Openscad, the gcode is what is output from Prusaslicer after the stl has been imported, rotated and moved to the south west quadrant.

Attaced ZIP here : miniusbpsu

Regards,

S

RE: Gaps in surface next to holes

@stanley-4

Hi Stanley, your Gcode is printing fine for me so far, 2.4mm thick just started the mounting perimeters

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Gaps in surface next to holes

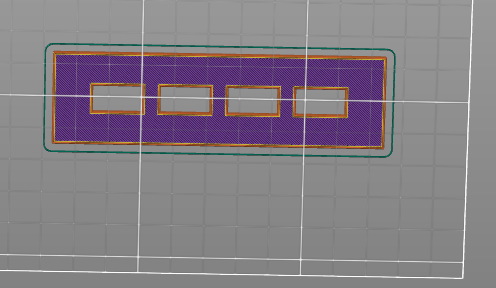

Successful print, no issues...

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Gaps in surface next to holes

@joantabb

Thank you Joan - that's above and beyond the call of duty 🤩

Hmm.

That would indicate that there is something wrong with either the printer settings, the printer hardware or the printer firmware. If you get a good print using the GCODE it would say thay my .stl is correct and so is the newly installed version of PrusaSlicer that generated the GCODE.

I can't see anything wrong with the X axis and it moves freely enough, the Y Axis is also free. I will go and get some IPA and a toothbrush and a good light and see if I can see anything (I'll blame cat hair for now 😘 ) to eliminate the hardware. I'll also have a go at calibrating the printer again to see if that makes a difference. Then I'll try another roll of filament and see what that does. I keep my filaments in vacuum sealed bags but just in case...

It's been up and running for over a year now and I've not really had any issues with the printer or process, this just seems to be odd.

I haven't quite ruled out the conspiracy theory that you are trying to drive me insane of course...

S

RE: Gaps in surface next to holes

Hi Stanley,

I can't comment on the Conspiracy theory, Coz 'They're watching Me too!"

Here's a picture of my effort, using your gcode...

regards Joan...

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Gaps in surface next to holes

@joantabb

It looks nice in white 😀 What material did you print it in ? That finish is incredibly smooth and I have never managed to achieve anything that good in all the printing I have done. My machine is the i3 Mk3 S+ as stock from Prusa - I have the MMU but haven't got round to using it yet, I've printed on PLA, PET3, ABS and Nylon (You need the glue and cardboard draught shields !!) but never got a finish as smooth as that one.

It's a good target to aim for 😎

RE: Gaps in surface next to holes

It's Cheap Chinese PETG. probably about £12.00 per Kg. on Ebay uk...

I am using a Mk3S printer,

Mine happens to have a Dragon Hot end, but I don't think that makes a big difference to the print quality. It certainly makes nozzle changes easier. which was my main reason for getting it, it also seems to melt a little more filament for larger nozzles. I have the standard flow version, the Hi Flow version is said to give similar performance to a Volcano hot end, without the loss of Z height due to the volcano being 11mm longer than the V6 hot end

all of the settings were your settings because you created the Gcode.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Gaps in surface next to holes

@stanley-4

Do a couple of one layer 40 cm patches and check your layer height, I get the impression that your just not quite dialed in on your height. When you print the patches try to get the gaps to go away there, perhaps when you print the patches change the infill angle to 0º so it runs on the x-axis only.

Stay safe and healthy, Phil

RE: Gaps in surface next to holes

@stanley, you didn't include the 3MF project file, so we can't verify your settings. What do you have Print Settings->Advanced->Overlap->Infill/perimeters overlap set to? I find 25% works well and helps with some of those issues. Also check Filament Settings->Filament->Filament->Extrusion multiplier to make sure it's not too low. Finally, you can try reducing speed to 50% with the front knob mid-print to see if that helps. Some filaments print better with slower speeds or hotter temps.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Gaps in surface next to holes

@pcweber

Hi Phil,

thank's for the suggestion.

I have other hobbies and a full time job and spent three hours yesterday evening cleaning, applying a light coating of silicon spray to the bearing surfaces and re-calibrating the printer. I also printed a sheet of 9 25mmx25mm patches 0.2mm thick and adjusted the z offset between the patches and found that my head was way too high. I noted the z offset for all the patches and then did a fingernail scratch on all the patches and found the smoothest one and used that as my layer one offset. The resulting print was a big improvement and is probably the best finished print I have ever managed so I am very happy 🙂 See a bit later on for a fuller explanation.

There is still a slight breakup on the surface but you have to look hard to see it and I will try altering the infill angle when I do the next print (I'm currently making some tweaks to it because, as with a lot of these things, printing them out highlights some areas for improvement that aren't immediately obvious on a screen.

S

RE: Gaps in surface next to holes

@stanley-4

A lot of people (including myself) like this way of optimizing live Z:

The only thing I do differently is to use a smaller square and vary Live Z within one square probably three or four times, not just once.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Gaps in surface next to holes

@bobstro

Hi Bobstro,

Thanks for the suggestions. I don't have a 3MF file 🙂 Until about 30 seconds and 1 google + 1 Wikipedia ago, I had no idea what a 3MF file was :-).

My models are built using openscad and I export the model as an stl file which I then import directly into prusaslicer, place it on the bed, slice it and export it to the SD card for printing. All done on Linux as well :-). It's a bit old fashioned after reading up about 3MF's but it's a fairly simple process and works well for me.

I checked Print Settings->Advanced->Overlap->Infill/perimeters overlap and it is set to 25%.

and Filament Settings->Filament->Filament->Extrusion multiplier is set to 1.

Everything is stock, I try to fiddle as little as possible - too many variables. When I have a go again at the print, I will have a close look and try tweaking the print speed and take on board the other suggestions to see if I can get even better results. I'm impressed with the quaility of Joan's print above and it has made me realise what a miserable standard I was happy with. I now have a good target to aim for and will hopefully improve my results with the advice from yourself and other so far 🙂

RE: Gaps in surface next to holes

@fuchsr

Hi,

I hadn't seen that and thought that my idea of printing out 0.2mm thick squares was original and brilliant then you come along and spoil it all for me 🤣

S

RE: Gaps in surface next to holes

@stanley-4

Yeah, life sucks!

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Gaps in surface next to holes

@stanley-4

Have you tried to do an linear adjustment to your k value of your particular filament?

Stay safe and healthy, Phil