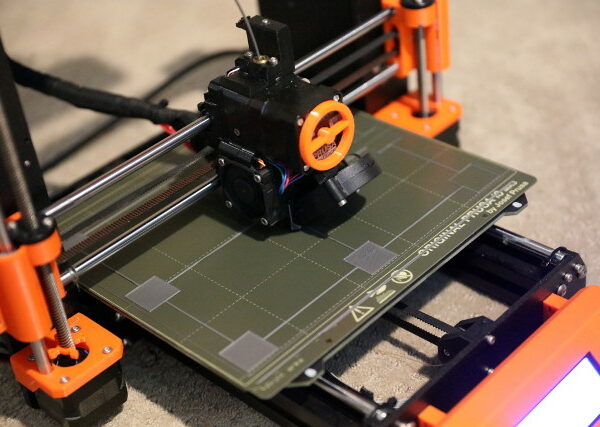

First print when getting new filament spool...

I used the search function, but it didn't really give me the results that I was hoping for. Sorry for the basic question.

I've just about blew through my "basic" filament roll, and I ordered in a bunch of new stuff that arrived yesterday.

When you get new filament, is a temp tower generally the first thing you print to evaluate the filament? I am thinking that benchy is more a mark of the overall printer's performance.

So, perhaps a temp tower and a sample card to store for reference? Is that the general approach?

RE: First print when getting new filament spool...

I personally print a swatch card because it's very useful to have those at hand instead of fumbling with spools to figure out which color to print something with.

The model I print is this one I made, which is a remix of someone else's design. To me it's just the right size: https://www.printables.com/model/59972-compact-filament-swatch

I only print temp towers or other tests prints like this when my prints are unsatisfactory and I want to optimize a filament's settings for better results. Say the layer adhesion is bad or there is too much stringing.

RE: First print when getting new filament spool...

Right - ok. So, all the spools I got in are the same manufacturer (Prusament), but they are just different colors. So, maybe I won't go printing temp towers for each.

I'm printing something now, and the first 3 attempts, I had some poor adhesion in the same spot on the print each time.

I'm just now wondering, when you switch filaments, it's probably a good idea to do a first layer again to adjust Z, yes? (Although, the temp tower printed just fine, which was the first print.) Or, do you find that you don't have to adjust much from one spool to the next assuming it is the same temp and material?

RE: First print when getting new filament spool...

If I understand well you have poor print adhesion on the heated bed. If that's the case, your Z is probably too high.

No need to adjust Z for each filament. Not even when you switch filament types. You only need to do it when you change steel sheet types or when you perform some more advanced maintenance such as re-positioning the PINDA sensor.

RE: First print when getting new filament spool...

I've always found very little difference between the major brands (Hatchbox, Overture, Paramount, etc.) of PLA, ABS, and PETg and even some of the cheaper lines such as Amazon Basics.

Once the Prusa is dialed in as far as Z calibration is concerned, all of the major brands and even minor brands seem to print consistently well using the default PS settings.

I've found little need to adjust parameters for most of the brands and types of filament. The only one that I recall being a significant exception is the Mika3d metallics, which seem to occasionally jam if the nozzle temperature is not bumped up a wee bit.

RE: First print when getting new filament spool...

Yes, the steel sheet, but specifically, one X-Y was the same spot where it was getting messed up.

If I understand well you have poor print adhesion on the heated bed. If that's the case, your Z is probably too high.

No need to adjust Z for each filament. Not even when you switch filament types. You only need to do it when you change steel sheet types or when you perform some more advanced maintenance such as re-positioning the PINDA sensor.

RE: First print when getting new filament spool...

OK - copy on the filament changes and Z.

Does anyone measure the thickness and width of the "initial line" at the bottom of the sheet (before it moves to actual part printing) for reference?

RE: First print when getting new filament spool...

When I do a Z calibration, I will carefully eyeball the zig-zag portion of the internal calibration pattern to be sure it has the desired oval profile, indicating the correct amount of 'squish', plus the underside of the 'flag' which is printed at the end of the pattern.

When I have it looking OK, I will follow up with a sanity check using one of those 3x3 single-layer test prints, which will verify the overall Z calibration, as well as show up any left/right and/or front/rear irregularities.

RE:

Generally there is no need to recalibrate except when switching to a different filament manufacturer or when a new variant of a filament is used.

Prusa's presets are good enough for 90% of the variation but oddities like wood/metal filled, silk, glow-in-the-dark and similar quite often need tweaks, as do some colours, white and very pale pastels sometimes contain so much pigment that they behave differently.

If you buy very cheap filaments; not a bad idea if you're doing a lot of prototyping, then the commonest issue used to be varying diameter 'though it's less frequent these days so measuring the true diameter and entering it into a specific preset is sometimes useful.

specifically, one X-Y was the same spot where it was getting messed up.

This is most likely to be surface contamination so a thorough clean may be enough.

Does anyone measure the thickness and width of the "initial line" at the bottom of the sheet

Not much point, this is the priming squirt that pushes out any overcooked filament in the nozzle and pressurises the hot end ready for use; expect it to be different every time.

Cheerio,