Extruder noise vs nozzle size

I believe I’m in a catch 22 situation, or clueless. I love the small nozzle quality. I want to use even smaller nozzles for some detail or ultra detail printing, using a .2, or .1 nozzle. However I don’t see a way to tell the printer from its own menu structure, that I changed the nozzle. Slicer is not even in the mix yet because I’m afraid to calibrate with the extruder noise. The printer wants to extrude at a .4 nozzle ratio and the smaller nozzles can’t pass or take that pressure, thus the extruder is clicking like crazy. Seems to me when you change the nozzle, this is a device level change and should be reflected in the menu structure. This would be a setting on the printer to define the nozzle installed and set the extruder speed accordingly. I can’t find where to change the feed rate on the printer, so it won’t be over driving the extruder. If I can’t change on the printer, I can’t do a first layer cal. Aka the catch 22. If I can’t calibrate, then I’m doa.

Am I missing something here, this seems like a really gross oversight not to associate a nozzle at the device level via menu so the feed rates are adjusted accordingly?

RE: Extruder noise vs nozzle size

Good Morning

If you wish to try different nozzle sizes there are a number of parameters that you need to adjust

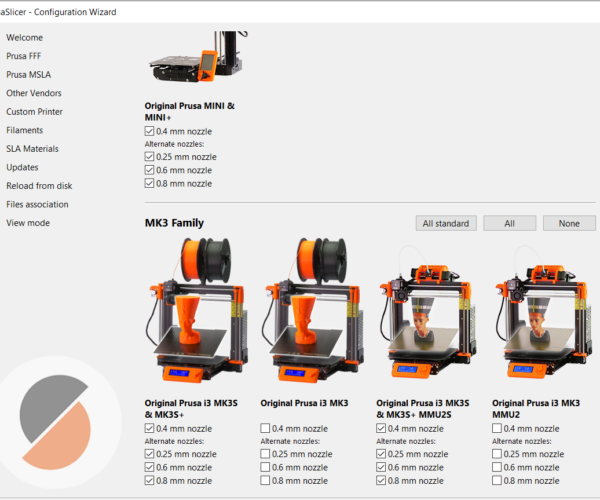

for a beginner, I would suggest that you start by using the pre programmed nozzle diameters as offered in Configuration Wizard

Unfortunately neither 0.2mm nor 0.1mm ate on the list

to create your own profile I suggest you start with the 0.25mm profile and work from there

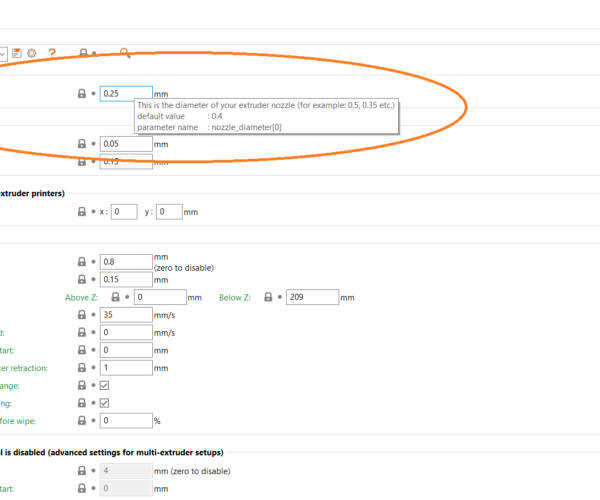

at the very lease, you will need to change the nozzle diameter

Note some of these parameters are only visible in Advanced or Expert mode

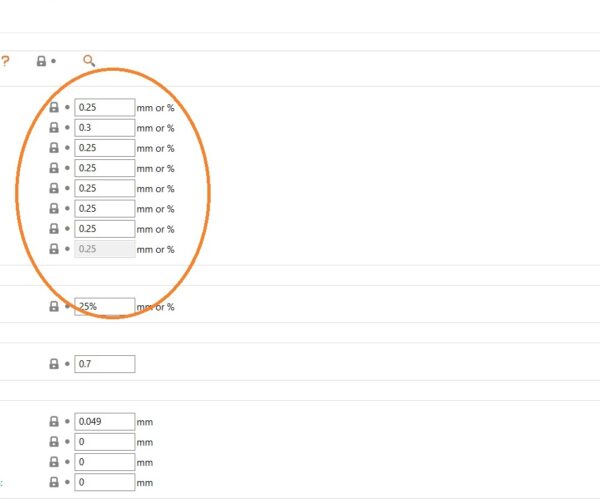

then you need to change the extrusion width to suit your needs

Please be aware that under normal circumstances the minimum first layer height on a Prusa Printer is 0.2mm, the Maximum layer height, should not exceed 80% of the nozzle diameter.

80% of a 0.25mm nozzle is 0.2mm

80%of a o.2mm nozzle is 0.16mm

80% of a 0.1mm nozzle is 0.08mm

both of the last two values are smaller than the normal minimum first layer height.

when working with small nozzles the extruder step size/definition becomes important, you may be better with a geared extruder

I believe One of the other forum users, Bobstro, has a set of personal notes relating to different nozzle sizes, which he makes available on the internet

Please also note that small nozzles block easily, they cannot handle the same range of filaments that larger nozzles can manage, so restrict yourself to plain colours. filled filaments like woodfill, or carbon fibre, will clog your small nozzle immediately.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extruder noise vs nozzle size

I think the OP's concern is how to run a first layer calibration after swapping nozzles if the built-in method is geared toward 0.4 mm nozzles.

I'd say that's a good excuse to ditch the stock method in favor of https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Just use your slicer to generate a calibration square for the different nozzle settings (use Joan's advice as needed for that) and then just pick whatever square you need after you swapped nozzles.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Extruder noise vs nozzle size

I believe I’m in a catch 22 situation, or clueless. I love the small nozzle quality. I want to use even smaller nozzles for some detail or ultra detail printing, using a .2, or .1 nozzle.

You want a nozzle size small enough to print the smallest details in your prints, but no smaller. Otherwise, you're just adding print time with no appreciable increase in print detail. I find a 0.25mm nozzle is ideal for printing detailed miniatures. I've got a bunch of notes on using different nozzle sizes here that might be useful.

However I don’t see a way to tell the printer from its own menu structure, that I changed the nozzle. Slicer is not even in the mix yet because I’m afraid to calibrate with the extruder noise. The printer wants to extrude at a .4 nozzle ratio and the smaller nozzles can’t pass or take that pressure, thus the extruder is clicking like crazy. Seems to me when you change the nozzle, this is a device level change and should be reflected in the menu structure. This would be a setting on the printer to define the nozzle installed and set the extruder speed accordingly. I can’t find where to change the feed rate on the printer, so it won’t be over driving the extruder. If I can’t change on the printer, I can’t do a first layer cal. Aka the catch 22. If I can’t calibrate, then I’m doa.

I do a Live-Z (1st layer) adjustment any time I swap nozzles. You're not stuck with the Prusa on-board Live-Z routine. As @fuchsr notes, there are alternative prints that are much easier to use and understand. I've got full notes as well as some test prints for various printers here that you can slice with your chosen filament and nozzle settings.

Am I missing something here, this seems like a really gross oversight not to associate a nozzle at the device level via menu so the feed rates are adjusted accordingly?

Prusa is adding new filament types and nozzle sizes to the firmware, but there is a finite amount of space. It's good to know how to slice your own test prints with your chosen nozzle and filament settings and do a good Live-Z calibration. In fact, what I learned on my Prusa has applied to other printers that I own, printing on everything from 100x100 to 300x300 bed sizes printing a wide range of filaments with a 1.2mm nozzle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…